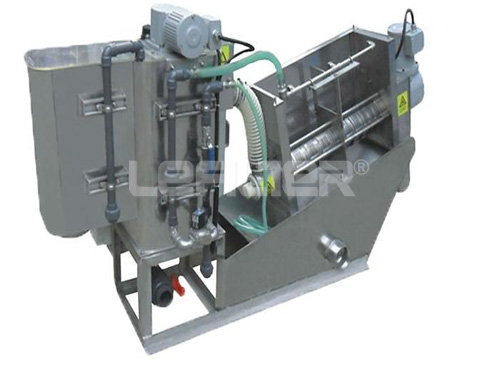

Structural Composition

Filtration Unit: Composed of multiple sets of parallel - arranged filter plates and frames. Filter media (such as filter cloths, filter papers) are placed between the plates and frames to form filtration chambers, increasing the filtration area.

Pressing Device: Adopts hydraulic, manual, or electric pressing methods. By applying pressure to the plates and frames, the filtration chambers are sealed to prevent material leakage.

Feeding and Liquid Discharging System: Includes feeding pipes, valves, liquid discharge pipes, and valves, enabling uniform feeding of materials and smooth discharge of filtrate.

Support and Base: Provides stable support for the equipment, ensuring reliable operation.

Working Principle:The material to be filtered enters the filtration chambers through the feeding pipe. Under pressure, the liquid passes through the filter media such as filter cloths or filter papers, enters the channels of the filter plates, and is then discharged. Solid impurities are intercepted on the surface of the filter media to form filter cakes. When the filter cake reaches a certain thickness or the filtration pressure reaches the set value, feeding stops. The pressing device is loosened, and the plates and frames are opened one by one to remove the filter cakes. After cleaning the filter media, the plates and frames are pressed again to start the next filtration cycle.

Core Advantages:Compared with other filtration equipment, the plate filter has a large filtration area and strong processing capacity. Different - precision filter media can be flexibly replaced according to material characteristics and filtration requirements. The plate - frame structure facilitates the observation and cleaning of filter cakes, making maintenance easy. It has a wide application range and can handle materials with various viscosities and particle sizes.

Preparation Stage

Check whether all components of the equipment are firmly connected and ensure that the valves of the feeding and liquid - discharging pipes are closed.

Install suitable filter media between the filter plates and frames and check the sealing performance.

Press the plates and frames through the pressing device to form sealed filtration chambers.

Filtration Stage

Open the feeding valve, and the material to be filtered enters the filtration chambers under the action of a pressure pump.

The liquid in the material passes through the filter cloths or filter papers, and is discharged from the liquid outlet through the channels of the filter plates. Solid impurities are intercepted to form filter cakes.

Observe the pressure gauge and flowmeter to monitor the pressure and flow changes during the filtration process.

Filter Cake Removal

When the filtration pressure reaches the set value or the filter cake reaches a certain thickness, close the feeding valve to stop feeding.

Loosen the pressing device, open the plates and frames one by one, and let the filter cakes fall off due to gravity or auxiliary external force. Clean the filter cakes manually or mechanically.

Media Cleaning and Equipment Reset

Clean the residual impurities on the surface of the filter media, check whether the filter media are damaged, and replace them in time if necessary.

Re - install the filter media, reset the plates and frames, and press them again through the pressing device to prepare for the next filtration.

| Features | Details |

|---|

| Efficient Filtration | The multi - set plate - frame design increases the filtration area, with a unit - time processing capacity of 5 - 100m³/h. |

| Flexible Adjustment | Different - precision and - material filter media can be replaced to adapt to the filtration requirements of various materials. |

| Convenient Maintenance | The plate - frame structure is easy to disassemble, and filter cake cleaning is simple. Maintenance can be completed by a single person. |

| Reliable Sealing | The hydraulic/electric pressing device ensures the sealing of the filtration chambers, preventing material leakage and ensuring a safe working environment. |

| Strong Durability | Made of high - quality stainless steel or anti - corrosion materials, it is corrosion - resistant and wear - resistant, with a service life of up to 8 - 10 years. |

| Wide Application | Suitable for multiple industries such as chemical, food, pharmaceutical, and environmental protection, and can handle materials with different viscosities and particle sizes. |

| Parameter Category | Specific Parameters |

|---|

| Processing Flow Rate | 5 - 100m³/h (customizable) |

| Filtration Area | 2 - 100㎡ |

| Operating Pressure | ≤0.8MPa |

| Operating Temperature | -10℃ - 80℃ |

| Plate and Frame Material | Stainless steel 304, stainless steel 316L, polypropylene (PP) |

| Filter Media | Polypropylene filter cloth, polyester filter cloth, filter paper, non - woven fabric, etc. |

| Pressing Method | Hydraulic pressing, manual pressing, electric pressing |

| Overall Dimensions | Customized according to the filtration area |

Chemical Industry: Filters chemical raw materials, intermediate products, and finished products, such as coatings, inks, resins, etc., to remove impurities and improve product purity.

Food and Beverage Industry: Used for filtering fruit juices, wines, edible oils, dairy products, etc., to separate pulp residues, suspended solids, and microorganisms and improve product quality.

Pharmaceutical Industry: Filters liquid medicines and suspensions, intercepts bacteria and insoluble particles, and meets the GMP standards of drug production.

Environmental Protection Field: Treats industrial wastewater and domestic sewage, separates solid suspended solids in water, and reduces pollutant content.

Metallurgical Industry: Filters metal working fluids and electroplating solutions, recovers useful substances, and reduces environmental pollution.

Oil Processing: Filters crude oil, removes impurities and phospholipids, and improves oil quality.

How to select suitable filter media for the plate filter?:When selecting filter media, consider the properties of the materials (such as acidity, alkalinity, viscosity, particle size), filtration precision requirements, and production processes. For example, polypropylene filter cloths resistant to acids can be selected for filtering acidic materials. For the pharmaceutical industry with high - precision requirements, filter papers with smaller pore sizes can be used. When dealing with high - viscosity materials, filter media with good air permeability should be chosen to prevent low filtration efficiency.

What should I do if the filtrate is turbid during the filtration process of the plate filter?:Turbid filtrate may be caused by damaged filter media, allowing solid impurities to penetrate. Stop the machine, check the filter media, and replace the damaged parts in time. It may also be due to poor sealing of the plates and frames, causing material leakage from the gaps. Check whether the pressure of the pressing device is sufficient and whether there are impurities on the sealing surface, clean the surface, and press the plates and frames again. In addition, excessive feeding pressure may break through the filter media, so the feeding pressure needs to be adjusted to an appropriate range.

The plate filter, with its efficient solid - liquid separation ability, flexible operation mode, and wide applicability, has become a key device for many industries to ensure production quality. Whether in the chemical and pharmaceutical fields with strict product purity requirements or in the food industry with strict hygiene standards, it can provide stable and reliable filtration solutions. Choosing our plate filter means choosing an efficient, flexible, and durable filtration equipment to escort the production process.

If you are interested in this product or have any questions, please feel free to contact us at any time.

Backwash filter

https://www.le-filter.com/self-cleaning-filter/backwash-filter/

Shallow sand filter

https://www.le-filter.com/wastewater-treatment/shallow-sand-filter/

{sval:sql sql='SELECT n_parameter FROM dede_addonarticle WHERE aid = ~aid~ ' } {/sval:sql}

{sval:sql sql='SELECT n_parameter FROM dede_addonarticle WHERE aid = ~aid~ ' } {/sval:sql}