The plate filter is an advanced filtration device designed to achieve efficient solid - liquid separation, offering reliable and precise filtration solutions for a wide range of industrial applications.

I. Product Introduction

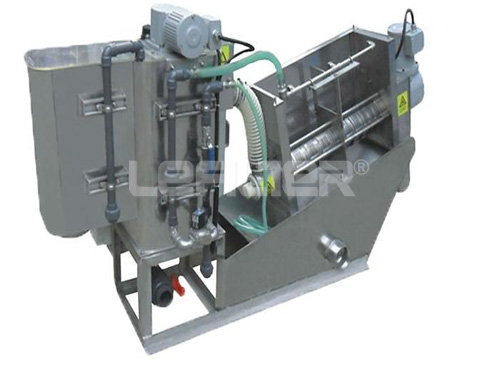

The plate filter is engineered with a unique structure. Its main components include a filter housing, multiple filter plates, and an assembly system for these plates. The filter plates, often made of high - quality stainless - steel mesh or other durable filter media, are vertically arranged within the housing. This configuration provides a large filtration area, enabling high - volume fluid processing. The filter plates can be customized according to different filtration requirements, such as varying the pore size of the mesh or choosing different types of filter media. Some plates are equipped with special surface treatments to enhance the adhesion and retention of solid particles during filtration. The plate filter can be designed as a manual - operation model for small - scale production or an automatic model with integrated control systems for continuous and large - scale industrial processes.

II. Working Process

Filtration Phase

Fluid Inflow: The fluid to be filtered, which is a mixture of liquid and solid particles, enters the filter through the inlet. It is then evenly distributed across the surface of the filter plates. The distribution mechanism is designed to ensure that the fluid flows uniformly, maximizing the utilization of the filtration area.

Solid - Liquid Separation: As the fluid passes through the filter plates, the pores in the filter media act as barriers. Solid particles larger than the pore size are retained on the surface of the plates, gradually forming a filter cake. The liquid, now free of these solid impurities, permeates through the plates and collects at the bottom of the filter housing. From there, it flows out through the outlet, ready for further processing or use.

Filter Cake Build - up and Monitoring

Continuous Filtration: During the filtration process, the filter cake on the filter plates gradually thickens. This build - up is monitored through various means. Some plate filters are equipped with pressure sensors that measure the pressure difference across the filter plates. As the filter cake thickens, the pressure difference increases. When this pressure difference reaches a pre - set value, it indicates that the filter cake has reached a certain thickness and may need to be removed or the filtration process adjusted.

Cleaning and Filter Cake Removal Phase

Manual Cleaning (for manual - operation models): In manual - operation plate filters, when the filtration efficiency decreases due to the thickening of the filter cake, the filter needs to be stopped. Operators then manually disassemble the filter housing to access the filter plates. The filter plates are removed and cleaned, usually by washing with water or other appropriate cleaning agents. The filter cake is physically scraped off or washed away, and the plates are then reinstalled for the next filtration cycle.

Automatic Cleaning (for automatic models): In automatic plate filters, the cleaning process is automated. Once the pressure difference or a pre - set time triggers the cleaning process, a reverse flow of clean fluid (such as clean water or compressed air) is introduced. This reverse flow scours the surface of the filter plates, loosening the filter cake. In some cases, mechanical vibration devices may also be activated to further assist in dislodging the filter cake. The loosened filter cake is then discharged from the filter through a dedicated outlet. The entire cleaning process can be completed within a few minutes, minimizing downtime and ensuring continuous operation.

III. Product Features

Key Advantages | Description |

High - Efficiency Filtration | The large - area filter plates and optimized flow path enable high - speed and high - volume filtration. It can handle fluid volumes ranging from several cubic meters per hour to hundreds of cubic meters per hour, depending on the model. |

Precise Filtration | With a wide range of available filter media, the plate filter can achieve filtration precision from a few microns to hundreds of microns, effectively removing various solid particles, ensuring the purity of the filtrate. |

Low Maintenance | The filter plates are durable and have a long service life. For automatic models, the self - cleaning function reduces the frequency of manual maintenance. Even for manual - operation models, the simple structure of the filter plates makes disassembly, cleaning, and reassembly relatively easy. |

Flexible Adaptability | Available in different sizes, filter media options, and operation modes (manual or automatic), the plate filter can be customized to adapt to various fluid properties, such as different viscosities, chemical compositions, and particle sizes. It can also operate under different pressure and temperature conditions. |

Cost - Effective | Compared to some other filtration equipment, the plate filter has a relatively low initial investment cost. Its energy consumption is also reasonable, and the long - lasting filter plates reduce the cost of filter media replacement, resulting in overall cost - effectiveness. |

Space - Saving Design | The vertical arrangement of the filter plates makes the plate filter have a relatively compact footprint. This is especially beneficial for installations in areas with limited space, such as in small - scale industrial plants or laboratories. |

IV. Technical Parameters

Parameter Category | Specific Parameters |

Filter Plate Material | Stainless - steel mesh, Polypropylene, High - performance filter cloth, etc. |

Filtration Precision | 1μm, 5μm, 10μm, 20μm, 50μm, 100μm, 500μm (customizable) |

Operating Pressure | ≤1.0 MPa (varies by model, some high - pressure models can reach up to 2.5 MPa) |

Operating Temperature | 5 - 80℃ (different filter media have different temperature resistance ranges) |

Single - unit Treatment Capacity | 5 - 500 m³/h (varies significantly depending on the size of the filter and the filtration conditions) |

Number of Filter Plates | 10 - 100 (varies by model) |

Backwash Medium (for automatic models) | Clean water, Compressed air, Air - water mixture |

Backwash Pressure (for automatic models) | 0.3 - 0.8 MPa |

Backwash Time (for automatic models) | 5 - 15 minutes |

Inlet/Outlet Pipe Diameter | DN25 - DN300 (customizable) |

V. Application Fields

Food and Beverage Industry

Beverage Production: In the production of wine, beer, juice, and soft drinks, the plate filter is used to remove yeast cells, suspended solids, and other particles. This improves the clarity, taste, and shelf - life of the beverages. For example, in wine production, it can filter out sediment and impurities, enhancing the visual appeal and quality of the wine.

Edible Oil Filtration: Filters impurities from crude oil, such as suspended solids and free fatty acids, to improve the quality and stability of edible oils. It can be used in the production of olive oil, soybean oil, and other types of edible oils.

Chemical Industry

Chemical Reaction Filtration: Separates catalysts, unreacted raw materials, and reaction by - products from chemical reaction mixtures. This is crucial for ensuring the purity of chemical products and facilitating subsequent processing steps. For example, in the production of pharmaceuticals, it helps to separate intermediate products from reaction solutions.

Wastewater Treatment: Removes suspended solids, heavy metals, and other contaminants from industrial wastewater, helping to meet environmental discharge standards. It can be used in the treatment of wastewater from chemical plants, electroplating factories, and other industrial facilities.

Pharmaceutical Industry

Drug Production Filtration: Filters drug solutions during the production process to remove particles, bacteria, and other contaminants, ensuring the safety and quality of pharmaceutical products. It is also used in the filtration of biological products, such as vaccines and enzymes.

Purification of Intermediate Products: Separates solid - phase substances from intermediate products in pharmaceutical synthesis, improving the yield and purity of the final drugs.

Environmental Protection Industry

Industrial Waste Gas Treatment: In some cases, the plate filter can be used to remove solid particles from industrial waste gas, reducing air pollution. For example, in metal smelting plants, it can filter out dust and other particulate matter from the exhaust gas.

Sludge Dewatering: Separates water from sludge in wastewater treatment plants, reducing the volume of sludge and facilitating subsequent disposal or resource utilization.

VI. FAQ

How often do the filter plates need to be replaced?

The replacement frequency of filter plates depends on various factors, including the nature of the fluid being filtered, filtration precision, and operating conditions. Under normal circumstances, stainless - steel mesh filter plates can last 1 - 3 years, while filter plates made of other materials may have different service lives. Regular inspection and monitoring of the filtration performance can help determine when the filter plates need to be replaced.

Can the plate filter handle highly viscous fluids?

Yes, but certain adjustments may be required. For highly viscous fluids, the filter may need to operate at a lower flow rate to ensure effective filtration. Additionally, the choice of filter media and the design of the filter plates may need to be optimized. For example, using filter media with larger pores or a more open structure can help reduce the resistance to flow for viscous fluids.

What should I do if the filtration efficiency of the plate filter decreases?

First, check whether there are any blockages in the inlet and outlet pipelines. Then, monitor the thickness of the filter cake. If the filter cake is too thick, it may be necessary to clean or replace the filter plates. For automatic models, ensure that the cleaning system is working properly. If the problem persists, it is recommended to contact our technical support team for further inspection and troubleshooting.

VII. Conclusion

The plate filter is a reliable, efficient, and versatile filtration solution. Its advanced features, such as high - efficiency filtration, wide adaptability, and cost - effectiveness, make it an ideal choice for numerous industries. Whether it's ensuring product quality in food and beverage production or contributing to environmental protection in wastewater treatment, this filter delivers consistent performance. Choose our plate filter to optimize your filtration processes, improve productivity, and reduce operational costs.

If you are interested in this product or have any questions, please feel free to contact us at any time.

VIII. Related Products

Hydraulic oil filter

https://www.le-filter.com/oil-purification/hydraulic-filter/

Replacement EPPENSTEINER filter element

https://www.le-filter.com/filter-element/EPE-filter/

{sval:sql sql='SELECT n_parameter FROM dede_addonarticle WHERE aid = ~aid~ ' } {/sval:sql}

{sval:sql sql='SELECT n_parameter FROM dede_addonarticle WHERE aid = ~aid~ ' } {/sval:sql}