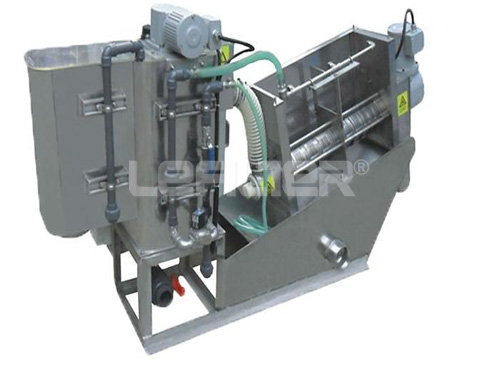

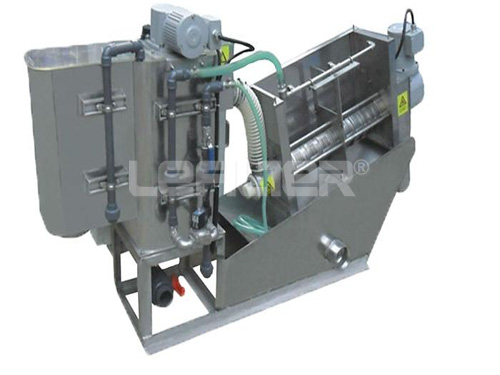

Equipment Introduction

The Sludge dewatering for waste water treatment plant developed by HOLLY utilizes the dewatering principles of force-water homo-direction, thin-layer dewatering, proper pressure and extension of the sludge dewatering path. The new equipment, more advanced than the traditional The Sludge dewatering for waste water treatment plant developed by HOLLY utilizes the dewatering principles of force-water homo-direction, thin-layer dewatering, proper pressure and extension of the sludge dewatering path. The new equipment, more advanced than the traditional dewatering equipment which are easily blocked, unsuitable for low-concentrated sludge and oily sludge, of high consumption and difficult to operate, well eliminate these problems and are of higher efficiency and power saving.

Main Features

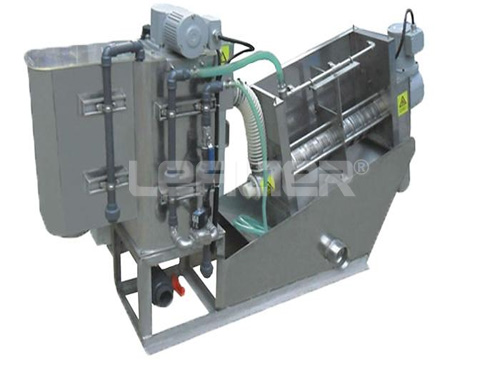

Exclusive pre-thickening device enables a wide solid concentration ranging from 3000mg/l to 50000mg/l

Exclusive pre-thickening device enables a wide solid concentration ranging from 3000mg/l to 50000mg/l

Fixed and moving plates replace filter cloth, self-cleaning, clog-free, easy to handle oily sludge

Fixed and moving plates replace filter cloth, self-cleaning, clog-free, easy to handle oily sludge

Low running speed, low noise, low power consumption, 1 /8 of Belt Press and 1 /20 of centrifuge

Low running speed, low noise, low power consumption, 1 /8 of Belt Press and 1 /20 of centrifuge

Less capital construction cost, more excellent working performance

Less capital construction cost, more excellent working performance

Fully automatic control, Easy operation and simple maintenance

Fully automatic control, Easy operation and simple maintenance

Advantages

Widely Use

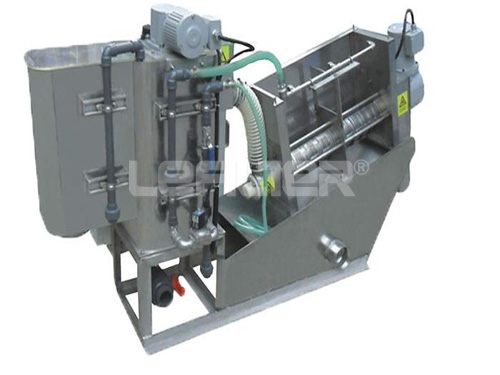

Applicable sludge concentration of 2000mg/L-50000mg/L.

Most especially for the oily sludge.

Fully Automatic Control

Combining with the auto control system, the machine runs very safely and simply and can be programmed according to the requirement of the users. It can operate automatically for 24 hours, unmanned.

Low Running Cost

Power-use: less than 5% of centrifuge.

Water-use: less than 0.1% of belt filter press. Polymer: saving around 60%.

Room: saving more than 60% of the investment for dehydration room.

Non-clogging

Self-cleaning with small amount of water.

Suit for Oily Sludge

No secondary pollution

The screw shaft rotational speed about 2~3r/min, no vibration and noise is very small .

Only need a small amount of water for self-cleaning, no secondary water pollution.

Sludge runs at a slow operating condition. The smell does not spread.

{sval:sql sql='SELECT n_parameter FROM dede_addonarticle WHERE aid = ~aid~ ' } {/sval:sql}

{sval:sql sql='SELECT n_parameter FROM dede_addonarticle WHERE aid = ~aid~ ' } {/sval:sql}