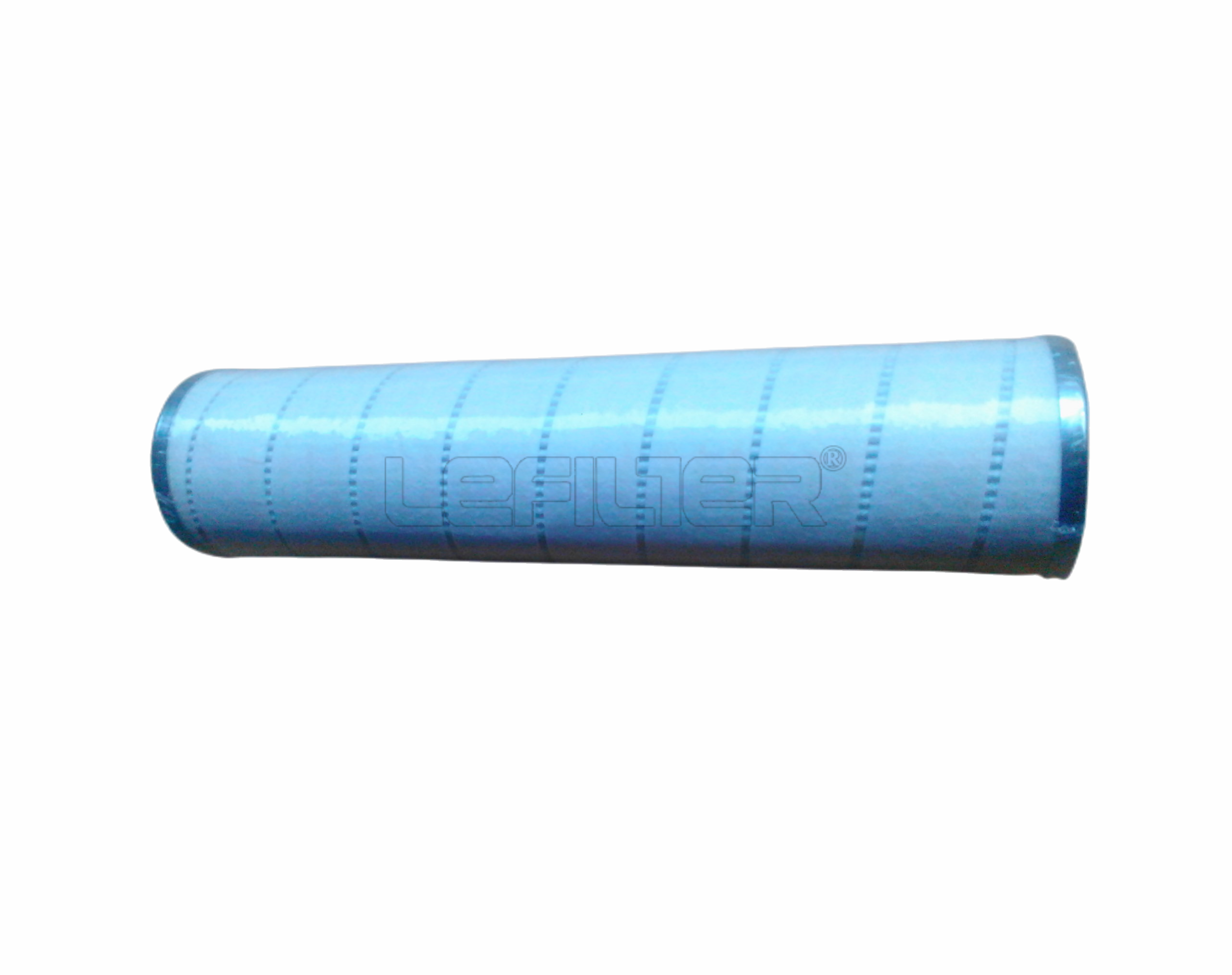

Made of multi - layer composite fiber materials, it efficiently removes dispersed tiny droplets and particulate impurities in oil products through the principles of coalescence and separation.

The core filter layer is processed by a special technology, which has excellent demulsification and coalescence capabilities for oil - water emulsions, ensuring the cleanliness of oil products.

With a modular design, it is compatible with various filtering equipment, meeting the fluid purification needs of multiple industries such as petrochemicals and electricity.

Fluid Inflow: Oil products containing impurities and moisture flow into the filter element from the outside, and large - particle impurities are initially intercepted by the outer coarse filter layer.

Coalescence Process: The fluid enters the coalescence layer, where tiny droplets collide, coalesce, and grow on the surface of special fibers.

Separation and Discharge: The coalesced large droplets settle to the separation layer due to gravity and are separated and discharged. Clean oil products flow out from the center of the filter element.

Pressure Difference Monitoring: The system continuously monitors the pressure difference before and after the filter element. When the pressure difference reaches the set value, it prompts the need to replace the filter element.

High - precision Filtration: The filtration accuracy can reach 0.1μm, effectively intercepting fine particles such as colloids and rust.

High Dirt - holding Capacity: The special structural design allows the filter element to hold more impurities, extending the service life by 40%.

Anti - pollution Performance: The oleophobic and hydrophilic coating on the surface reduces oil adhesion and lowers the risk of blockage.

High Temperature and Pressure Resistance: It can operate stably under the working conditions of 80℃ and 1.6MPa, adapting to complex environments.

| Item | Parameter Range |

|---|

| Filtration Precision | 0.1 - 10μm |

| Working Pressure | ≤1.6MPa |

| Working Temperature | -10℃ - 80℃ |

| Material | Glass fiber, polypropylene |

| Applicable Media | Lubricating oil, diesel oil, hydraulic oil, etc. |

Petrochemical Industry: Crude oil dehydration and purification of chemical raw material oil.

Electric Power Industry: Removal of moisture and impurities in turbine lubricating oil and transformer oil.

Transportation Industry: Fine filtration of marine fuel oil and aviation kerosene.

Industrial Manufacturing: Circulating purification of hydraulic oil for machining equipment.

Question 1: How often does the coalescing filter element need to be replaced?

Answer: The replacement cycle is affected by factors such as the degree of medium contamination and flow rate. Generally, when the pressure difference between the inlet and outlet of the filter element reaches 0.3MPa, or the service life exceeds 6 - 12 months, it is recommended to replace the filter element.

Question 2: Can the coalescing filter element handle different types of oil products?

Answer: Yes, it can. However, it is necessary to select filter elements with suitable materials and precision according to the characteristics of the oil products (such as viscosity and composition). Before use, it is recommended to provide the parameters of the oil products, and professional personnel will recommend the appropriate model.

The efficient coalescing filter element has become a key component in industrial fluid treatment with its precise water removal and purification capabilities. Its excellent performance can effectively protect downstream equipment, reduce maintenance costs, and provide reliable solutions for oil product purification in various industries.

Microporous Pleated Filter

PP Melt-Blown Filter

{sval:sql sql='SELECT n_parameter FROM dede_addonarticle WHERE aid = ~aid~ ' } {/sval:sql}

{sval:sql sql='SELECT n_parameter FROM dede_addonarticle WHERE aid = ~aid~ ' } {/sval:sql}