Introduction

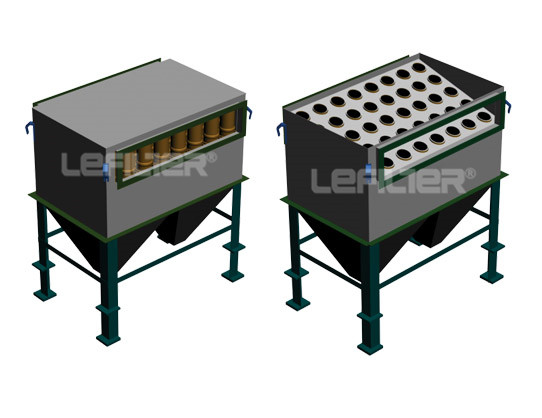

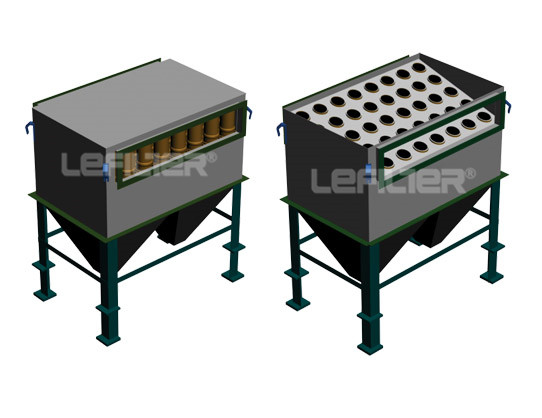

Ceramic multi-tube dust collector is a new-generation high-efficiency low-resistance dust removal equipment researched and developed by the company. It has corrosion resistance, wear resistance, high temperature resistance, no clogging, long service life, simple operation management, no cost, no secondary pollution. The advantages are the ideal dust removal equipment for the boiler.

It is a high-efficiency dust collector. The efficiency can reach more than 95%. The main body resistance of the dust collector is less than 900Pa. The existing boiler induced draft fan can ensure the normal operation of the boiler. The dust collector has good load adaptability, and the dust removal efficiency is above 94% at 70% load.

The filter in the Ceramic multi-tube dust collector is made of cast iron or ceramic and has athickness of more than 6mm, so it has good wear resistance. It is ideal for industrial boiler flue gas dedusting and other dust management.

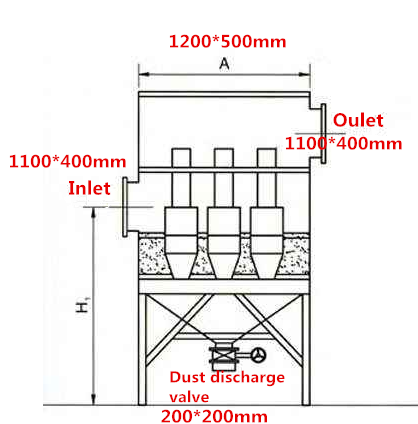

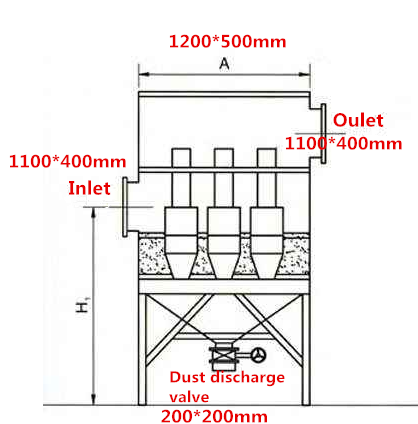

Schematic diagram

The dust collector is a cyclone type dust collector. When the dust-containing gas enters the dust remover and passes through the ceramic guide, the dust rotates at a high speed inside the cyclone. Under the action of the centrifugal force, the dust and the gas are separated, and the dust falls in the dust box and is discharged. The ash valve is discharged, and the purified gas forms a rising swirling flow, which is collected in the plenum through the exhaust pipe, and is discharged from the chimney through the outlet to achieve the dust removing effect.

Installation:

a) Pay attention to the collision during transportation and installation, handle gently.

b) During installation, all the flanges should be connected with the asbestos rope, and bolted tightly to prevent air leakage and affect the dust removal efficiency;

c) After the using of the investment, it is necessary to ash on time, generally not more than 4 hours - to prevent excessive dust collection in the dust box;

d) The unit used by the design shall use the dust collector according to the exhaust volume of the boiler and the flow rate of the flue gas, and provide space for the use of the unit boiler dust collector;

e) When the ash is discharged, the induced draft fan must be closed first. The ash outlet is strictly forbidden to be hit with a shovel. It is often checked whether the ash outlet is sealed.

Reliable manufacturers

Reliable manufacturers

High quality products

High quality products

Excellent service

Excellent service

Favourable prices

More details, contact Jessie:

Favourable prices

More details, contact Jessie:

E-mail/Skype: export01@lefilter.com

Mob/Whatsapp: 0086-17630717330

Tel: 0086-373-2618077

{sval:sql sql='SELECT n_parameter FROM dede_addonarticle WHERE aid = ~aid~ ' } {/sval:sql}

{sval:sql sql='SELECT n_parameter FROM dede_addonarticle WHERE aid = ~aid~ ' } {/sval:sql}