The important sources of waste gas in steel industry are: (1) a large number of dust containing waste gas in the process of transporting, handling and processing of raw materials and fuels; 2. A large number of dust and harmful exhaust gases will appear in the process of re consumption of all kinds of kilns in iron and steel plants; (3) waste gases from the process of consumption process, such as smelting, burning, and melting, will be reflected in the process of consumption. Waste gas generated during pickling process of steel products and steel products. The emission of waste gas in iron and steel enterprises is very large, and the pollution surface is wide; the exhaust gas temperature of metallurgical kiln is high, and most of the emission in the process of iron and steel smelting is iron oxide dust. It has small size and strong adsorption capacity, which increases the difficulty of the management of waste gas; the appearance of flue gas in the blast furnace, slag, and other processes in the steelmaking process. Emissions are paroxysmal, and are also emitted by unorganized emissions. The waste gas of iron and steel industry has the value of recovery, such as the waste heat recovery of high temperature, coke making and iron making, the use of gas in the process of steelmaking, and the recycling of iron oxide dust.

working principle of dust collector

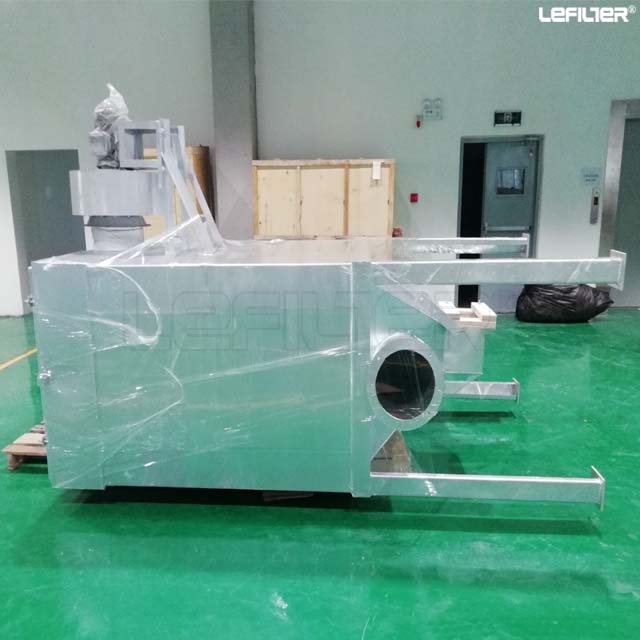

The dust remover in the steel plant is made of filter bag made of porous filter cloth to separate dust particles from the flue gas flow. When working, the flue gas flows out of the filter bag, and the dust particles are blocked outside the filter bag.

The term for cloth bag dust includes 2 processes such as collecting dust (separating dust particles from the air from the air) and regularly clearing the dust (removing the collected dust particles from the filter cloth).

The basic conditions for collecting dust are: (1) dust particles must collide with the fiber surface (or with dust particles blocking the fibers). (2) dust particles must be blocked on the surface of fibers (or with dust particles blocking fibers).

There is a common misconception about the dust removal mechanism of the bag filter: the filter is like a fine sieve, only the dust particles smaller than the sieve hole can pass through. However, the diameter of the fiber is more than one order of magnitude larger than the average particle size of the dust particles. The dust removal of the bag dust collector occurs first by the collision and attachment of the dust particles to the surface of the filter fabric.

There are five basic mechanisms for the deposition of dust particles on filter bags. (1) interception: when a dust particle moves along the flue gas flow to the surface of a single fiber, only when it is within the radius of a particle, interception occurs. (2) inertial collision: when a particle of dust is unable to move rapidly enough and abruptly changing streamlines near a fiber because of its inertia, the dust particles collide from the streamline to the fiber. (3) diffusion: dust particles collide with fibers due to Brown motion. (4) gravity: larger particles fall due to gravity leaving the flue gas flow. (5) electrostatic attraction: electric charges on dust particles / fibers produce electrostatic attraction between fibers and dust particles.

{sval:sql sql='SELECT n_parameter FROM dede_addonarticle WHERE aid = ~aid~ ' } {/sval:sql}

{sval:sql sql='SELECT n_parameter FROM dede_addonarticle WHERE aid = ~aid~ ' } {/sval:sql}