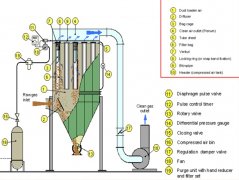

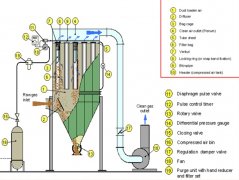

The working principle of LFEF series dryer glass fiber bag dust collector:

1, filter: dust smoke into the intake pipe through the flue, from the upper into the intake chamber, part of the coarse particles falling into the ash bucket by inertia, the rest of the smoke dust into the filter bag, through the inner surface filter, into the bag room, and then through the ventilator, exhaust valve, outlet pipe air exhaust fan into the air, the equipment for the upper air, the equipment for upper intake, The filter type glass fiber bag dust collector in negative pressure operation.

2, ash cleaning and automatic control: after a period of time, the dust layer on the inner surface of the filter is thickened, and the running resistance of the dust collector rises. When the filter is increased to a certain value, it needs to clean the filter bag, that is, remove the dust attached on the inner surface of the filter bag by external force, so that the running resistance of the dust collector is reduced. After the resistance drops to a certain value, the filter bag of the room is put into operation again.

The whole process is mainly through the air blowing. When the resistance rises to the need of dust cleaning, the microcomputer command closes the exhaust valve, opens the anti blowing valve, and presses the original expanded dust filter bag under the action of the back blow, and makes it reach the dust dust on the surface of the cleaning filter bag. The ash is discharged into the ash hopper and discharged through the ash discharge valve into the ash conveying mechanism. The whole cleaning process is carried out in a separate room without affecting the normal work of the dust collector.

Structural features:

1. The air intake, exhaust and back blowing system of the glass fiber bag type dust collector, including the intake pipe, the intake chamber, the back blow valve, the anti blow tube, the three pipe, the exhaust valve and the exhaust pipe.

2. Bag room structure of fiberglass bag filter: including ash hopper, maintenance door, body frame, upper and lower flower plate, filter bag and bag room.

3. Dust discharge system of fiberglass bag filter includes ash discharge valve and screw conveyor.

{sval:sql sql='SELECT n_parameter FROM dede_addonarticle WHERE aid = ~aid~ ' } {/sval:sql}

{sval:sql sql='SELECT n_parameter FROM dede_addonarticle WHERE aid = ~aid~ ' } {/sval:sql}