A Polypropylene (PP) micro-pore folding filter cartridge is a type of water filter constructed from polypropylene, a thermoplastic polymer possessing resistance to chemical corrosion and heat. The foldable design increases the surface area used for filtration which, in turn, enhances its effectiveness.

Its key feature is the micro-pores on the filter surface that effectively trap and eliminate impurities from the fluid passing through. The pores range from 0.1 to 60 micrometers, enabling the filter to remove particulates, such as dust, and microorganisms, like bacteria.

Since polypropylene is resistant to a range of chemicals, these filters are compatible with various fluids, from acidic to basic solutions, making them appropriate for many different industrial applications.

The foldable configuration of the filter increases the filtration area significantly, which allows it to capture a larger volume of impurities before a replacement or cleaning is necessary. This high dirt-holding capacity cuts down the need for frequent maintenance.

Given its construction material, polypropylene filters can resist higher temperatures, making them suitable for filtering hot fluids. Moreover, their d

esign ensures they are physically stable, which leads to consistent performance, lower instances of cartridge collapse and a longer lifespan.

The working principle of a Polypropylene (PP) micro-pore folding filter cartridge is predicated on both overlapping physical properties and the process of filtration.

Constructed from a thermoplastic polymer, the filter cartridge has a unique folded design that effectively enlarges the surface area for filtration. This increased surface area means more fluid can be filtered at a time, enhancing its efficiency.

When water or another type of liquid is channeled into the filter cartridge for purification, it flows into the inner core through the folded filter media. The micro-pores present on the filter surface trap any impurities, contaminants, or particles as the fluid navigates through the filter.

The size of these micro-pores is specific and can range between 0.1 to 60 micrometers. Due to this specific pore size, the filter is capable of removing particulates, bacteria, dust, and other microscopic impurities from the fluid. This process ensures that only clean and purified liquid passes through to the other side.

This filtration process is purely mechanical and does not involve any chemical reactions, making it a safe and effective method for purifying various types of fluids from water to chemicals.

Polypropylene, the fundamental material used to make the filter, is known for its chemical resistance and heat tolerance, qualities that allow for the filtration of both hot and chemically-loaded fluids. The robust and durable nature of the filter ensures that it can consistently provide high performance over an extended service life.

In conclusion, the working principle of a PP micro-pore folding filter cartridge involves the mechanical process of filtration, harnessing the physical properties of a specially designed folded filter media to purify various types of fluids effectively and efficiently.

The PP Micro-Pore folding filter cartridge offers several significant advantages and exhibits unique characteristics which make it useful in a wide array of applications, from home purification systems to industrial-scale filtration processes. These are predicated on the filter's construction, functionality, and the material it's made of - polypropylene.

Superior Filtration Capabilities: Thanks to its small pore size ranging from 0.1 to 60 micrometers, the filter can effectively trap a considerable range of impurities, including microorganisms and dust particles. The removal of such microscopic contaminants is essential to produce high-quality filtered fluid, whether it is for drinking, pharmaceutical manufacturing processes, or industrial fluid power systems.

Increased Surface Area: Due to the unique folded design of the filter, it has a larger filtration area as compared to conventional filters. Such a design offers higher dirt-holding and contaminant-separation capacity, increasing the longevity of the filter and reducing maintenance frequency.

Heat and Chemical Resistance: The filter is made from polypropylene, a thermoplastic polymer known for its resistance to both high temperatures and a wide range of chemicals. This allows for the safe filtration of high-temperature liquids, as well as the purification of corrosive or chemically complex fluids. This feature makes the filter applicable across a broad spectrum of industries.

Physical Rigidity: The build quality and design of the PP micro-pore folding filter cartridge make it physically rigid, reducing the chances of filter collapse under high-pressure operating conditions. This stability ensures consistent performance and extends the overall lifespan of the filter.

Broad Compatibility: Given the material and design, these filters are compatible with a multitude of systems and substances from water purification systems to the chemical industry, food and beverage processes, pharmaceutical production, and beyond.

In conclusion, the PP Micro-Pore folding filter cartridge presents distinct advantages and exhibits unique characteristics in its design, material and filtration capability. This enables it to deliver efficient and effective performance across diverse applications.

Polypropylene, the material used to construct PP Micro-Pore folding filter cartridges, is known for its excellent resistance against a variety of chemicals and high temperatures.

High-Temperature Resistance: Polypropylene has a good degree of heat resistance. It can withstand temperatures up to 100 degrees Celsius (212 degrees Fahrenheit) in continuous operation. This makes it suitable for filtering hot fluids without losing its efficiency as a filter, ensuring both durability and consistency.

Chemical Resistance: One of the most significant properties of polypropylene is its resistance to many aggressive chemicals. This resilient thermoplastic displays excellent resistance against most acids, alkalis, and other organic solvents, allowing it to maintain integrity and functionality in chemically complex environments. This chemical resistance does not scale evenly for all substances, with certain high-concentration chemicals causing degradation over long-term exposure. However, for a majority of standard applications, this level of resistance serves quite aptly.

In conclusion, Polypropylene exhibits an impressive scale of resistance toward both high temperatures and a vast range of chemicals, contributing greatly to the versatility, longevity, and applicability of PP Micro-Pore folding filter cartridges in various challenging environments.

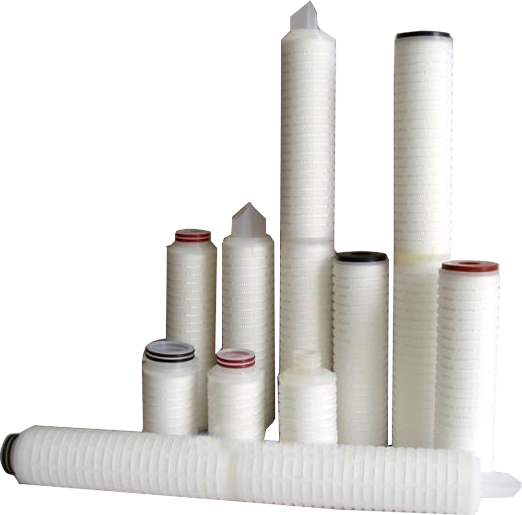

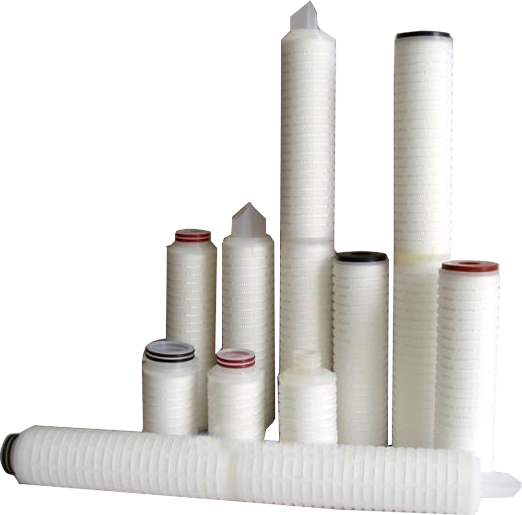

The PP Micro-Pore folding filter cartridge is a unique component crucial for filtration systems across various industries. The principle factors behind its functionality stem from its complex yet efficient construction design and its composition from various grades of Polypropylene (PP).

Structure and Composition: The body of the PP Micro-Pore folding filter cartridge is created from layers of polypropylene that are thermally bonded together, ensuring greater structural integrity and avoiding the use of adhesives that may contaminate the filtered substance. The design approach with a folded structure grants the filter a high surface area, allowing for increased rates of filtration and a larger volume of contaminant capture.

Filtration Function: The purpose of the PP Micro-Pore folding filter cartridge is to purify fluids by removing minute impurities that contaminate them. The arrangement of micro-pores on the surface of the filter cartridge trap particles of varying sizes, contaminants, and microorganisms, depending on the pore size of the filter.

Graded Pore Structure: The cartridges have a graded or tiered pore structure. The outermost layer has a larger pore size which first traps bigger impurities, while the subsequent inner layers possess progressively smaller pore sizes to capture finer particles. This design enhances the longevity of the filter by preventing the smaller pores from getting prematurely blocked, thereby aiding in comprehensive filtration.

Polymer End Caps and Core: Each cartridge is fitted with polypropylene end caps and core. These are not merely structural elements but also have a purpose in ensuring the purity of the filtered fluid as they do not leach out any contaminants.

Support Cage: Surrounding the pleated material is a support cage or net that adds to the stability of the filter, fortifying it against the pressure exerted during the filtration process.

In short, the PP Micro-Pore folding filter cartridge is a meticulously designed piece of advanced filtration technology. Its sophisticated structure composed of polypropylene enables superior and consistent filtration performance, contributing significantly to maintaining purity standards across a variety of industries.

The PP Micro-Pore folding filter cartridge is a meticulously designed filtration device, each specification and parameter carefully chosen to maximize filtering efficiency across various applications. A detailed overview of its standard specifications includes:

Material: The filter media, end caps, and inner core are all manufactured from polypropylene (PP), an excellent material choice due to its heat resistance and chemical stability.

Pore Sizes: Filter cartridges are typically available in a range of pore sizes to suit varying applications, ranging from 0.1 microns to 60 microns. The variety in pore sizes allows for flexibility in choosing the level of filtration necessary, with smaller sizes offering more intricate filtration.

Cartridge Lengths: The cartridges are customizable and can be made available in multiple lengths, typically starting from 5 inches and going up to 40 inches. The length corresponds to the surface area of the filter and thus impacts filtering capacity and the lifespan of the cartridge.

Diameter: The standard outer diameter of the cartridge is about 2.7 inches or 69mm, with an inner diameter of approximately 1.1 inches or 28mm.

Operating Temperature: PP Micro-Pore folding filter cartridges can function effectively in temperatures up to 82 degrees Celsius.

Maximum Differential Pressure: With a maximum differential pressure of 35 psi at normal room temperature (20 degrees Celsius), these filters can withstand significant pressure differences across its body.

Flow Rate: The exact flow rate of the cartridge depends on specific variables, including the type and viscosity of the fluid, size, and quantity of impurities, filter pore size, and operating pressure in the system. However, these cartridges are designed to facilitate high flow rates while maintaining filtration efficiency.

Compatibility: Due to the chemical resistance of polypropylene, these cartridges can filter a vast range of fluids, including water, solvents, acids, and alkalis.

In summary, the PP Micro-Pore folding filter cartridge is a versatile and robust filtration device with a wide range of specifications and parameters, each contributing to its efficient operational capacity in various filtration applications.

The future of the condensate water filter market appears to be promising, with various factors contributing to its substantial potential for development and success.

Growing Market: The water purifier market, which includes systems like condensate water filters, has been forecasted to have exponential growth. The market size crossed USD 43 billion in 2023 and is projected to expand at a 7.5% Compound Annual Growth Rate from 2024 to 2032. This growth is fueled by rising concerns about water pollution and the increased necessity for purification systems to ensure safe and potable water.

Tech Advancement: Technological advancements in the water purification market are expected to further fuel this industry's progression. These developments aim to increase filtration efficiency, reduce energy consumption, and further the environmental sustainability of these devices.

Rising Safety Concerns: The growing concerns about municipal water safety have amplified the need for reliable home water filtration systems. The condensate water filter, being one such system, is positioned favorably to meet this rising demand.

Market Demand: The global demand for clean and safe water is fuelling the water filtration housing market's significant growth, which directly impacts the condensate water filters' intrigue.

Increased Awareness: As people become more aware of the importance of water purity and the potential health risks posed by contaminated water, the demand for effective and robust filtration systems like condensate water filters is only anticipated to rise.

Residential Market Growth: The global residential water filtration parts & accessories market was valued at USD 9.50 billion in 2023 and is expected to reach USD 13.88 billion by 2029, providing further impetus for the development and advancement of products like condensate water filters.

In conclusion, the condensate water filter market, due to the rising necessity for efficient water filtration systems and backed by technological advancements, is set on a trajectory of considerable growth and development. This market's future certainly appears to be abundant with opportunities, promising for significant advances in water filtration technologies and practices.

The condensate water filter unravels an effective solution to addressing issues of water purification, directly intertwining with global efforts to promote environmental sustainability and public health. An assessment of its environmental performance and societal impact reveals the following:

Promoting Water Conservation: Water conservation stands as a significant environmental focus, and the condensate water filter plays a pivotal role in this area. By purifying and reusing condensate water, this device contributes to a more efficient utilization of water, thus conserving this precious resource.

Minimizing Waste: The use of these filters allows for an effective capture of impurities that would otherwise contaminate the water bodies where the waste water would have been discharged. This practice reduces the load of waste entering the water bodies and hence aids in preserving our aquatic ecosystems.

Discouraging Synthetic Chemical Usage: Unlike some other water purification methods, condensate water filters do not depend on harsh chemicals to purify the water. This reduces the chemical footprint of the water purification process, thereby contributing to a healthier environment.

Bolsters Public Health: From a societal perspective, the availability of clean, safe water thanks to such filters directly translates into health benefits by reducing the risk of water-borne diseases. This measure greatly elevates the public health standards in societies where such filtration systems are installed.

Creates Jobs and Boosts Economy: The manufacture, distribution, installation, and maintenance of condensate water filters stimulate job creation in these sectors. This in turn contributes positively to the local economy.

Fosters Sustainable Behaviour: The adoption of these filters in households promotes sustainable behavior and encourages people to consider the environmental impact of their daily choices. It acts as a catalyst in creating a more eco-conscious society.

Education and Awareness: The implementation of condensate water filters also serves as an opportunity to educate the public about water conservation and the importance of water purity.

In finality, the eco-credentials of the condensate water filter model create considerable societal impact, encompassing areas of public health, environmental sustainability, and economic stimulus. The application of these filters goes beyond just the product usage and extends into larger areas of global improvements and progress.

The effective use and maintenance of a condensate water filter are crucial to the overall performance of the system. Here’s a comprehensive guide discussing the routine use and upkeep of such filters.

Regular Use: The condensate water filter is an integral part of the HVAC/radiator system, with the primary role of filtering and removing impurities from the water drawn from these systems. The water passes through the filter, any impurities or contaminants are caught in the filter media, ensuring that only pure water is reused or discharged.

Weekly/Monthly Checks: It's crucial to conduct routine inspections of your water filter system to be on the lookout for any signs of leakage or defects. Pay specific attention to the pressure gauge reading. In most systems, an increase in pressure indicates a clogged filter that needs replacing.

Filter Replacement: Over time, the filtering media will become clogged with the impurities it has trapped. When this occurs, you will need to replace the filter cartridge. The frequency of replacement largely depends on the quality of the water being filtered, although most filters need replacing every 3-6 months.

Cleaning: Regular cleaning of the filter housing and connectors is an important maintenance task. It helps to prevent the buildup of impurities or bacterial growth that can affect the performance of the filter. Always shut off the water supply before removing the cartridge for cleaning or replacement.

Seek Professional Help: If you encounter major systemic issues or find it challenging to replace a cartridge, seek help from a professional. Trying to fix major issues without proper knowledge can lead to system damages or ineffective filtration.

Record-Keeping: It is a good practice to keep a record of filter changes, maintenance tasks, or any issues you've encountered and how they were resolved. This record can be helpful for troubleshooting future problems and for providing information to a professional if necessary.

Always Use Genuine Cartridges: To ensure optimal performance and longevity of your filter system, always use genuine replacement cartridges designed for your specific model. Non-genuine parts may be less efficient or may even cause damage to your system.

In conclusion, the longevity and optimal performance of your condensate water filter depend on regular use and diligent maintenance. By following these guidelines, you can ensure your system continues to function efficiently and provide you with clean, safe water for a long time.