A condensate water filter core, more commonly known as a condensate filter cartridge, is an integral component of systems where clear, contaminant-free water is required. In essence, this device works to filter condensed water, removing any impurities or harmful substances that the water may have acquired in its natural or human-aided cycle.

The main function of a condensate water filter cartridge is to help maintain the quality and safety of water in a variety of applications, ranging from industrial to residential use. It works by capturing impurities and contaminants like rust, sediment, and even microscopic bacteria. As water passes through, these impurities get trapped within the filter's mesh-like structure.

This in turn allows clean and safe water to be repurposed for consumption or use in processes that require high water purity. With the increasing environmental concern and the need for sustainability, the condensate water filter cartridge plays a pivotal role in reducing water wastage and ensuring water is reused to the fullest extent possible. It underpins many systems that require a high degree of water cleanliness, filtering out impurities and allowing only the cleanest water to flow through.

Not only does the use of a condensate water filter cartridge promote health and cleanliness, but it also contributes to the efficiency and longevity of the systems in which it is used. By removing these harmful particulates before they have a chance to build up or cause damage, a condensate water filter cartridge can extend the lifespan of system installations and significantly reduce maintenance costs over time.

In summary, the condensate water filter cartridge serves as a fundamental prerequisite for maintaining water purity, promoting sustainability and increasing system efficacy. Without this vital component, water contamination can have detrimental effects on systems and the users they serve. The prevention of these effects underlines the importance of this key component in numerous applications.

The working principle of a condensate water filter cartridge is centered around physical filtration and sometimes, chemical adsorption, depending on its design and the specific requirements of the system in which it is installed.

Primarily, the condensate water filter cartridge functions using a porous material as the filtration medium. This could be made of several different materials including spun fiber, activated carbon, ceramic, or even a composite of several materials. The primary role of this medium is to provide a physical barrier to impurities in the water while allowing the water molecules themselves to pass through.

As the condensate water enters the cartridge, it is directed towards the filtration medium. Due to the nature of the porous material, water molecules are much smaller than the pores and can pass through unhindered. In contrast, larger impurities such as rust particles, sediment, or even microorganisms are unable to pass through the tiny pores, thereby effectively filtering the water.

Particularly, in cartridges that include an activated carbon layer, a secondary process known as adsorption occurs. Activated carbon has the ability to adsorb certain chemicals and impurities from the water, including chlorine, color, and certain types of organic matter. This is usually used in applications where the removal of these specific compounds is essential.

In essence, the working principle of a condensate water filter cartridge involves a balance between filtration and flow rate. The effective filtering of impurities must not compromise the flow rate of water through the system to ensure optimum operation. This is achieved by careful design consideration and selection of suitable materials for the filtration medium. Consequently, the condensate water filter cartridge thus plays a pivotal role in the quality, safety and efficiency of water systems across a broad range of industries and domestic applications.

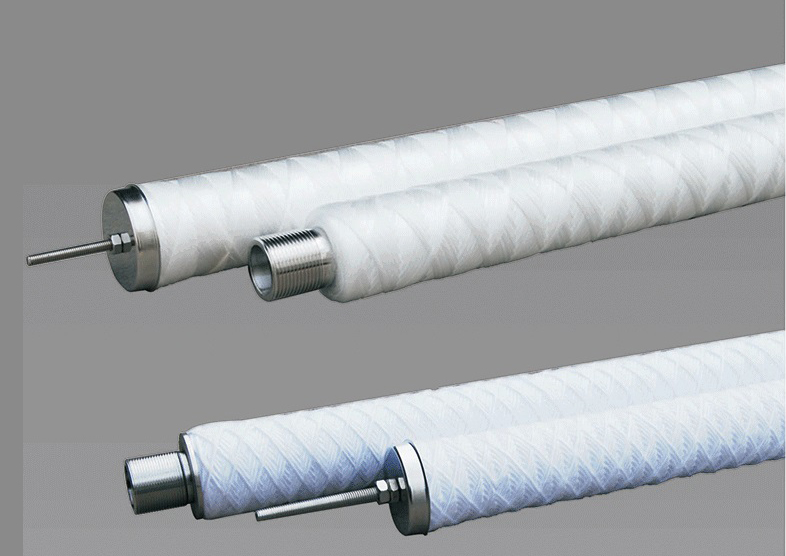

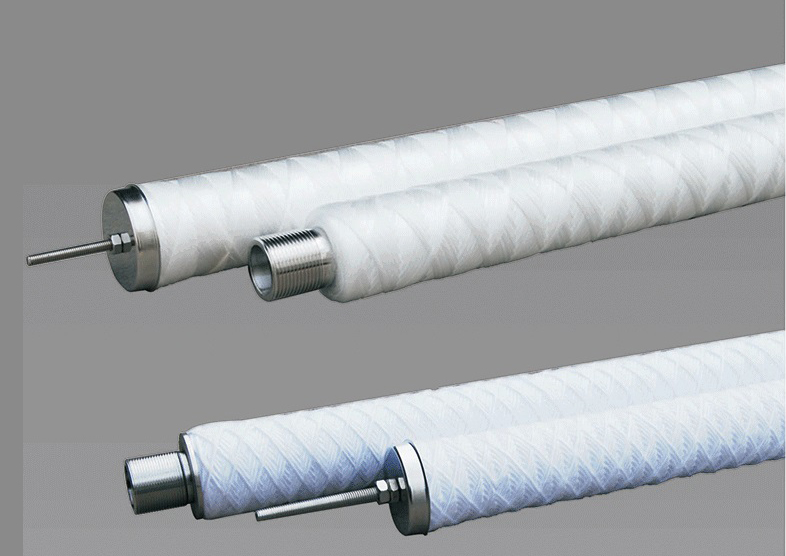

The structure and composition of a condensate water filter cartridge is an intricate combination of various components, each designed to effectively perform its role in the filtration process.

At the core of this system is the filter medium, a porous substance that physically filters the water passing through. Depending on the application requirements, a variety of substances may be used here. Among the most common are activated carbon, spun fiber, ceramic, or sometimes a mixture of several materials.

Around the filter medium, a durable outer casing, usually made from a sturdy plastic or metal material, is designed to protect the filter medium and ensure its longevity. This casing is typically designed to easily fit within the broader system, ensuring hassle-free replacements when necessary.

At each end of the cartridge, there may be specially designed caps or ends that aid in the fitting of the cartridge within the filtration system. These are also usually made from strong, durable materials that can withstand the pressure and conditions within the system.

For some designs, additional layers may be included within the cartridge. These may include pre-filters for removing larger particles before water reaches the primary filter medium. Similarly, post-filters may be used to ensure water quality by removing any remaining fine particles after the main filtration process.

Some cartridges also include a layer of activated carbon. This adsorptive material is capable of removing certain types of chemicals and impurities, by attracting and binding the impurities to its surface. It's especially effective for removing odors, discoloration, and chlorine.

In summary, the structure and composition of a condensate water filter cartridge is a finely-tuned combination of components. Each component has been meticulously designed and constructed to deliver effective, long-lasting, and trouble-free water filtration. From the filter medium to the casing and end caps, each element plays a crucial role in delivering the high-quality, clear, and safe water.

The specifications and parameters of a condensate water filter cartridge can vary widely depending on the intended application, the type of impurities to be removed, and the overall design of the water system. However, generally speaking, some common specifications include the following:

Size and Dimension: Standard filter cartridges are often designed in a cylindrical form to fit most filter housings. Common diameters include 2.5 inches and 4.5 inches. Lengths generally vary between 10, 20, 30, or 40 inches, while custom sizes may also be available, depending on the supplier.

Material: Depending on the nature of the filtration, cartridges can be made up of polypropylene, ceramic, activated carbon or other high-grade filtration materials. Each has its own performance specifications and suitability for certain types of water treatment.

Micron Rating: This specifies the size of particles that the filter cartridge is capable of removing and can be anywhere from 0.2 to 100 microns or more. The smaller the micron rating, the finer the filtration.

Capacity: The amount of water that a filter cartridge can process before it needs to be replaced is typically measured in gallons. This depends on factors like the quality of water and the size and type of impurities present.

Flow rate: This is the rate at which the water can pass through the cartridge, typically measured in gallons per minute (GPM).

Working Pressure: The operational pressure range within which the cartridge can safely function.

Operating Temperature: The range of temperature within which the cartridge can operate effectively.

Life Span: Typically determined by the amount of impurities in the water and frequency of usage, the cartridge's life span can range from several months to a few years.

These are general specifications, and the actual parameters may differ from one product to another based on its design and the manufacturer's credentials. Hence, it is vital to choose the right filter cartridge specifications and parameters that best fit your specific needs to ensure high-quality water filtration.

The use of condensate water filter cartridges brings several advantages. Here are some of the key benefits one can expect from these specialized filter systems:

Efficient Filtration: With specially designed cartridges that can target specific impurities, filter cartridges provide a high degree of filtration efficiency. Whether it's removing particulates, bacteria, chemicals, or odors, these cartridges can deliver clean, safe water.

Versatility: Cartridges come in various sizes, material compositions, and micron ratings, making them adaptable to a wide range of applications, from household use to industrial systems.

Easy Installation and Replacement: Filter cartridges are designed to be easily installable and replaceable. This makes maintenance processes relatively simple, saving time and effort.

Cost-Effective: Compared to more complex filtration systems, using filter cartridges can be a cost-effective solution. They require less upfront investment, and maintenance cost is usually low as well.

Environmentally Friendly: Many cartridges are made from materials that are recyclable or that have a low environmental impact. This makes them a greener option than some other kinds of filtration systems.

Durable and Long-Lasting: Quality filter cartridges are usually designed to be durable, able to withstand the rigors of operating under high pressures and over long periods. This means a longer lifespan and fewer replacements.

Improved Water Quality: By removing a broad range of contaminants, filter cartridges can significantly improve the overall quality of water. This can enhance the taste and odor of the water and promote better health.

Protective to Equipment: By filtering out potentially damaging debris and corrosive elements, filter cartridges protect the inner workings of the larger water system, reducing the chance of damage and extending the life of the equipment.

In conclusion, condensate water filter cartridges offer numerous advantages that ensure efficient and effective filtration. They are an integral component in water purification systems, both at small-scale domestic levels and in large-scale industrial operations.

Condensate water filter cartridges find applications in numerous industries due to their effective filtration capability and versatility. Here are some primary industries where they are extensively utilized:

Power Generation: Power plants, particularly those that utilize steam turbines, often need to filter the condensate water to remove impurities that could damage the turbines. Filter cartridges help to ensure the condensed steam is pure and safe for reuse.

Pharmaceutical and Healthcare: The pharmaceutical industry requires high-quality water for various processes. Filter cartridges are used to eliminate potential contaminants from the water, ensuring it meets strict purity standards.

Food and Beverage: In the production of consumable goods, the need for clean and safe water is paramount. Therefore, filter cartridges are used to purify water used for cooking, washing, producing drinks, and other processes.

Oil and Gas: In oil and gas industries, water often plays a crucial role in various operations, making the use of filter cartridges vital for water purification. They help remove contaminants that may interfere with processes or damage equipment.

Semiconductor Manufacturing: The production of semiconductors requires ultra-pure water. As such, condensate water filter cartridges are used in water treatment processes to ensure the highest level of purity is achieved.

Chemical Industry: The chemical industry makes extensive use of water. To prevent unwanted reactions and ensure process efficiency, the water used in these industries often go through rigorous filtration processes involving filter cartridges.

HVAC Systems: Heating, Ventilation, and Air Conditioning systems often generate condensate that needs to be filtered before it can be reused or disposed of. Condensate filter cartridges play a crucial role in this context.

Textile Industry: The textile industry requires massive amounts of water for various processes such as dyeing, washing, and finishing. To ensure the water does not stain or negatively affect the fabrics, it is thoroughly purified using filter cartridges.

In conclusion, due to their excellent filtration properties, durability, cost-effectiveness, and adaptability, condensate water filter cartridges are used in a wide variety of industries.

The future market prospects and development trends for condensate water filter cartridges are promising and continue to be shaped by various underlying factors. Here are some insights into their future market and trends:

Market Growth: The global demand for clean and safe water, coupled with the emphasis on environmental sustainability, is predicted to drive significant growth in the filter cartridge market. Water scarcity issues in many parts of the world also reinforce the need for efficient water filtration systems.

Technological Advances: Advances in filtration technology are expected to introduce more efficient and longer-lasting filter cartridges. Innovations might include the development of new materials for cartridge construction, improvement in cartridge design, and optimization of overall filtration performance.

Customization Trend: As different industries have specific water filtration requirements, there is an increasing trend towards customization of filter cartridges to suit precise needs. This adaptability is likely to become more prevalent in the future, further solidifying the role of filter cartridges in various sectors.

Regulatory Influence: Stricter environmental and health regulations worldwide will likely boost the market for water filter cartridges. These regulations often mandate certain water purity standards, which can be effectively met through the use of filter cartridges.

Sustainability Focus: With growing consciousness towards environmental sustainability, there is a shift towards eco-friendly materials and processes in producing filter cartridges. The focus on reducing environmental footprints can further drive advancements in filter cartridge technology.

Expanding Applications: As industries continue to recognize the benefits of using filter cartridges in their processes, their applications are likely to expand further. Emerging industries such as renewable energy might also become significant users of filter cartridges.

In conclusion, the future for condensate water filter cartridges seems bright, fueled by technology advancements, market demand, environmental consciousness, and evolving industry needs. These factors together are expected to drive considerable growth and innovation in the filter cartridge market.