Our customers

Circulating water pretreatment equipment needs to be designed according to the actual situation of the site, LEFILTER provides a full set of on-site measurement, scheme design, installation and commissioning, after-sales service.

―Equipment selection: self-cleaning water filter

In the whole social development, the iron and steel industry is very prominent in water and wastewater discharge, especially in the face of increasingly serious water shortage, coupled with the requirements of low carbon economy, the iron and steel industry recycling water treatment has been widely concerned. Although the recycling efficiency of water in iron and steel industry is increasing and the chemical oxygen demand in wastewater is decreasing, there is still a certain gap when compared with the world advanced level. In the future development, iron and steel enterprises still attach great importance to the development and utilization of energy, strengthen the rational use of water resources, and adopt the advanced environmental protection technology. Fundamentally promoting iron and steel industry in the rational use of water resources and sewage treatment and reuse should be greatly improved.

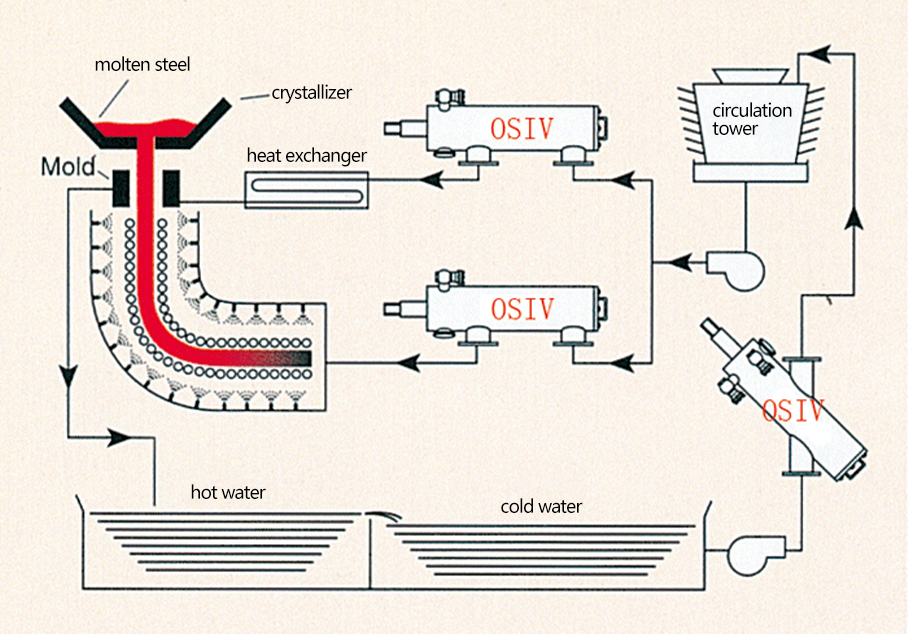

The consumption of circulating cooling water accounts for 50%~90% of the total water consumption of iron and steel industry. Different supplemental water sources have an impact on both the period of the problem and the degree of harm. As in the continuous industrial production process, with the extension of the operation cycle, the concentration ratio increases, and suspended matter and dust substances breeding by microorganisms lead to changes in water quality, lead to heat exchanger scaling, corrosion and pipeline impurities and suspended matter in the continuous accumulation of solid matter and other problems occur frequently, increase energy consumption, reduce the service life of equipment, and form security risks. Controlling the water quality parameters reasonably can improve the water reuse rate, save water resources, and greatly improve the overall situation of circulating cooling water. First of all, the cost of water is relatively high. Second, energy cycle efficiency is not high. Third, improve the concept and awareness of environmental protection in the whole society. Fourth, the lack of sound environmental protection policies. With the progress of society, people attach more and more importance to environmental protection. Therefore, in order to seek development, iron and steel enterprises pay more attention to the discharge of wastewater and the pursuit of zero discharge goal.

Overview:Self-cleaning water filter’s filter precision is from 100 to 3000 microns optional, it has large filtration area and high pollution capacity, users can be customized according to the actual working conditions. The cleaning method is simple, and the cleaning is cycle monitored, it can realize automatic cleaning sewage, and the automatic filter control system of all parameters can be adjusted. It has motor overload protection system, which can effectively protect the motor.

Application: electric power, reverse osmosis pre-stage, petrochemical, fine chemical, food and beverage, automobile industry, metallurgy, paper making, medicine, microelectronics, environmental water treatment and other industries.

Circulating water pretreatment equipment needs to be designed according to the actual situation of the site, LEFILTER provides a full set of on-site measurement, scheme design, installation and commissioning, after-sales service.

The self-cleaning water filter produced by our company is the preferred product for the filtration in the circulating cooling water system of steel mills. It can not only effectively filter out the heat exchanger’s fouling and corrosion and the impurities and suspended objects in the pipeline to generate solid objects, and reduce the frequency of system problems; but also realizes the online cleaning at the same time. The characteristics of continuous flow ensure the whole system flow circulation system and improve the stability of the circulating water. And unmanned operation, through the pIc remote online monitoring and control of system implementation, checks the stability of the system, greatly reduces the labor intensity and dangerous degree, effectively reduces emissions of waste water, strengthen the recycling, and reduces the operating cost of enterprises to achieve sustainable development of enterprises.