CUSTOMIZATION SERVICE PROCESS

Provide customization services according to different working conditions

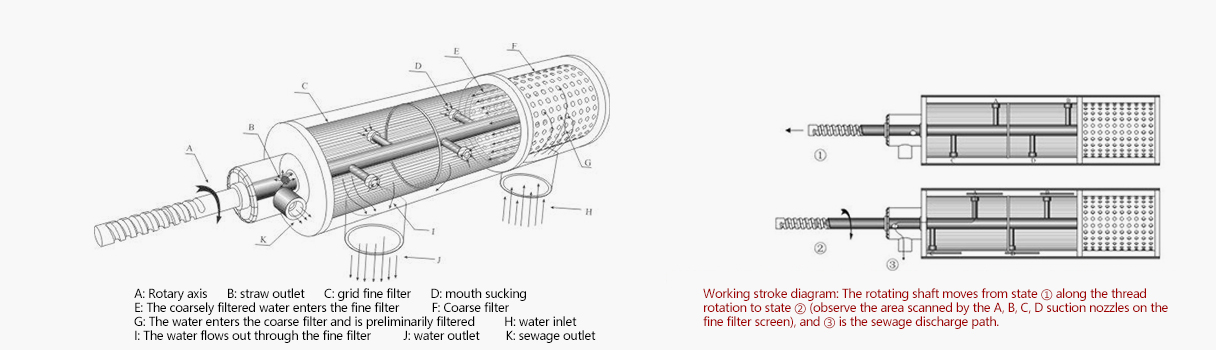

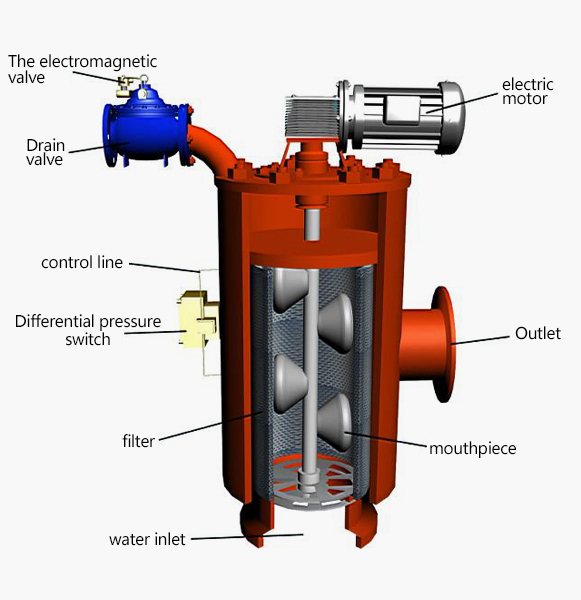

Working principle

First of all, the water passes through the coarse filter screen at the inlet to remove the larger impurities, and then passes through the fine filter screen to remove the smaller impurities. In the filtration process, the fine filter

screen gradually accumulates dirt and impurities, forming a impurity layer which is piled up in the inner side of the fine filter screen, then a differential pressure is formed on the inside and outside sides of the fine filter

screen.

When the pressure difference of the filter inlet and outlet reaches the preset value or when the preset cleaning time is reached or when the filter is manual preset, the automatic self-cleaning process will begin, and the

water supply is not cut off during this self-cleaning process. The whole self-cleaning process consists of two steps: the sewage discharge valve is opened, the water pressure in the cleaning chamber and the sewage suction pipe

greatly decreases, and there will be a pressure difference between the filter element and the sewage suction pipe, the suction pipe and the cleaning chamber will produce a suction process through the suction nozzle, forming a sewage

suction process. Impurities in the inner wall of the screen are sucked up by the suction scanner and discharged through the drain valve. At the same time, the external bidirectional motor drives the suction scanner to scan spirally.

The combination of axial movement and rotary movement of the suction pipe will completely clean the inner surface of the filter screen. The whole process takes only a few seconds. The drain valve closes at the end of cleaning.

The filter begins to prepare for the next flush cycle.

Cleaning mode: The filter's back cleaning mode adopts motor driving and suction nozzle sucking. The reducer and motor drive the suction device and suction nozzle to rotate, and suction nozzle sucks impurities on the inner

surface of the fine screen to complete the suction. The whole operation process of the self-cleaning filter is controlled by an intelligent control box equipped with it. Control mode is optional (pressure difference, time, manual

and PLC control).

Advantages

Suction nozzle design

Suction nozzle design:

mesh surface filtration, online intelligent cleaning and various cleaning forms

Reverse cleaning and energy saving

Reverse cleaning energy saving:

short reverse cleaning time, small pressure loss and less water is consumed by sewage discharge, which shall not exceed 1% of the total flow.

Various control modes

Various control modes:

the control modes include differential pressure, time and manual, which can be set arbitrarily

Key components of equipment

Key components of the equipment: the shell is carbon steel, the filter screen is stainless steel, the service life is long, and the filter screen is used for life without replacement

Technical Specification

Shell: carbon steel, 304 stainless steel, 316L stainless steel Filter screen: 304 stainless steel, 316L stainless steel

Brush holder: 304 stainless steel, 316L stainless steel Blowdown valve: cast iron, stainless steel

Controller: copper Sealing ring: EPDM rubber

Customized according to different working conditions

Production Field

Pictures

Details

Video

Cases

Purpose: circulating water treatmentFlow: 1000t/h

Purpose: cooling water treatmentFlow: 200t/h

purpose: ultrasonic cleaning solutionflow: 100t/h

Provide customization services according to different working conditions

Professional installation team to ensure the normal operation of the equipment

Technical Support