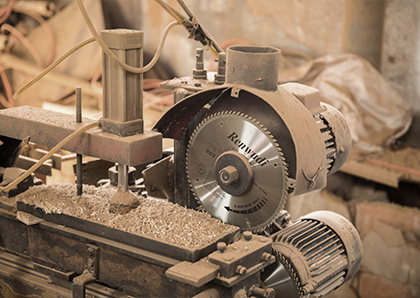

Equipment configuration and requirements

While meeting the production needs, it reduces maintenance costs and facilitates maintenance, improves the stability and safety of the equipment, and enables it to have a high-efficiency dust collection effect.

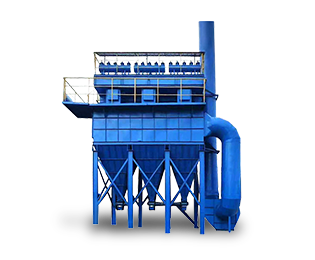

The project uses Lefilter GMC-200 bag filter, 30-channel pulse controller, screw conveyor, detachable maintenance platform and dust removal accessories and other products.

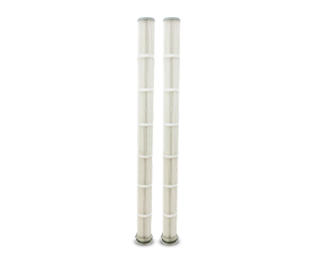

The total height of the bag filter equipment is not more than 3.5 meters (the height of the factory building is 5 meters), and the length is not more than 4.5 meters. The filter bag is made of antistatic needle felt material ≤10mg/m³。