A reverse osmosis (RO) equipment is a water purifying system designed to filter out trace impurities and contaminants using the process of reverse osmosis. The equipment features an RO membrane, which filters out contaminants as small as 0.001 microns in size under pressure.

An integral part of the system are pre and post filters; they not only enhance the longevity and efficiency of the RO membrane by trapping larger particles but also improve the taste and odor of water. The system uses a pressure pump to drive untreated water through the RO membrane, thereby enhancing the filtration process. The purified water accumulates in a pressure tank, ready for use as and when required.

The equipment also comes with an automatic shut-off valve (ASO) that conserves water by shutting off the water supply to the RO system when the storage tank fills up. Additionally, it incorporates flow restrictors that adjust the water flow rate through the RO membrane, thus ensuring optimal performance.

RO equipment finds application in residential homes, commercial establishments, industrial operations, and healthcare facilities. Whether it's for producing high-quality drinking water, purifying wastewater, for food and beverage processing, or pharmaceutical production, the utility of RO equipment is far-reaching. It provides a peace of mind that the water you consume is clean, free from potentially harmful contaminants, and safe.

In the long run, investing in RO equipment proves more efficient and cost-effective compared to reliance on bottled water, making it a worthwhile choice for both homes and businesses.

Reverse osmosis (RO) equipment utilizes a fascinating and complex scientific process to purify water. At its core, it's about using pressure to force a solution through a membrane, letting water pass through while holding back contaminants.

Initially, the water to be purified is introduced to the system. This water, under pressure, is driven towards the RO membrane, a semi-permeable layer designed to allow only water to pass through while rejecting the contaminants.

The pressure is crucial in the process as it has to overcome osmotic pressure. The applied pressure forces water through the membrane, and the contaminants are left behind. This separation under pressure is the "reverse osmosis" from which the process draws its name.

The purified water, also known as permeate, is then collected on the lower pressure side of the membrane. It is taken to a storage tank and kept ready for immediate use, while the remaining water containing the rejected impurities, termed as the concentrate or brine, is drained.

One significant aspect of RO equipment working principle is its 'cross filtration' method, unlike the typical filtration where contaminants are captured within the filter. In cross filtration, the solution passes through the filter, with the filtered water going one way and the contaminated water going another way. This method helps to avoid the filter getting clogged with contaminants.

Ultimately, reverse osmosis equipment provides a reliable and efficient way for water purification. By applying pressure to force water molecules through a semi-permeable membrane while leaving contaminants behind, it delivers purified water that’s safe and healthy to consume.

The semi-permeable layer of the Reverse Osmosis (RO) membrane is the fulcrum on which the entire process rests. This thin layer, made up of a synthetic polymeric material, is densely packed with pores so tiny that they are only a few Angstroms (a unit of length equivalent to one ten-billionth of a meter) in size. This minuscule pore size is crucial in acting as a barrier to almost all types of impurities present in water.

The fundamental idea behind RO filtration relies on the selective permeability of the membrane, which is to allow only specific substances to pass through, in this case, water molecules. As water is forced against the membrane under pressure, only the smaller water molecules can navigate through the microscopic pores, leaving behind larger molecules of contaminants and impurities.

Talk about these impurities; they could be anything from salts, heavy metals, microorganisms, to larger particulates. Due to the difference in size and polarity, these substances cannot pass through the dense semi-permeable layer of the membrane and are effectively screened out from the purified water.

Besides size exclusion, another essential mechanism at work is the charge repulsion. Many contaminants in water are charged particles, and because the RO membrane is also charged, it repels contaminants of the same charge. This adds another layer of security in ensuring the purity of the water.

In essence, the semi-permeable layer of the RO membrane does a stellar job of rejecting impurities while allowing water molecules to pass through. It is this fine balance that lends the reverse osmosis process its immense efficiency and effectiveness in water purification.

The semi-permeable layer of RO membrane, also known as the active layer, is typically composed of a synthetic polymeric material. This material is chosen for its ability to withstand the rigors of the filtration process, remain stable under varying water conditions and, importantly, to show the selective permeability required for effective filtration.

The most commonly used polymeric material is a compound called Polyamide (PA). Polyamide is excellent for rejecting a wide variety of solute molecules, especially salts - making it the perfect choice for the RO filtration process. This layer is often made via a chemical process known as the Interfacial Polymerization (IP), where two reactive monomers come together to form the thin, yet sturdy polyamide layer.

Other materials such as Cellulose Acetate (CA), Polysulfone (PS), and Polyethersulfone (PES) are also used, especially in older or specialized RO systems. Different materials offer different pros and cons, such as resistance to chlorine, pH tolerance, and fouling propensity.

In conclusion, the semi-permeable layer of the RO membrane is made up of a synthetic polymer, most often Polyamide - the compound that gives RO membranes their selective permeability, durability, and high filtration efficiency.

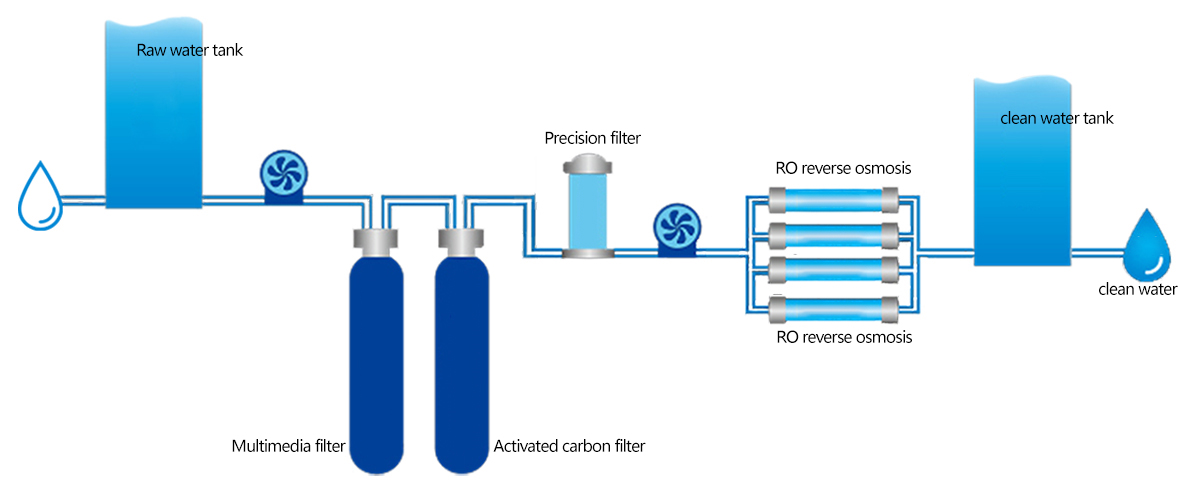

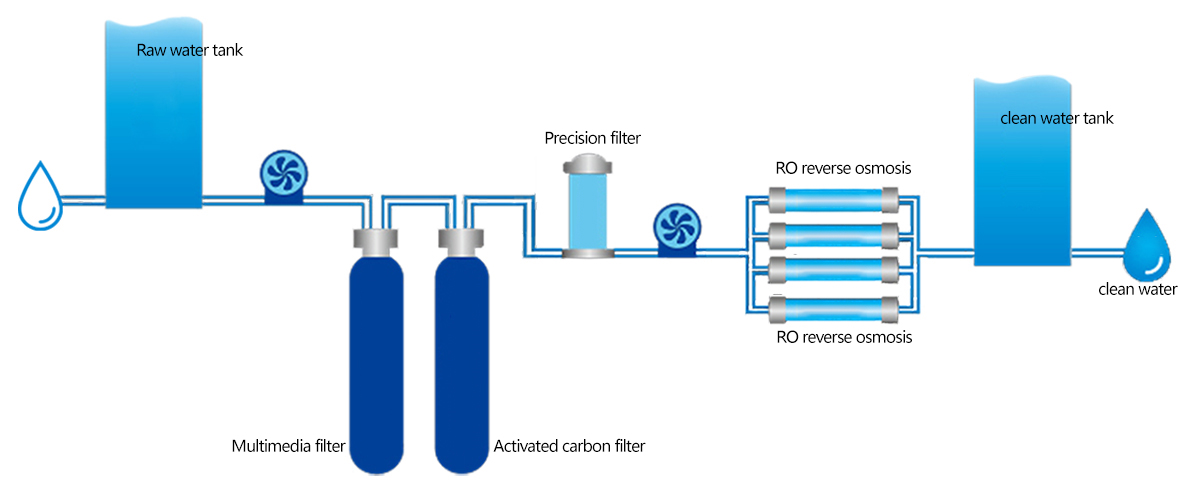

A Reverse Osmosis (RO) system is a powerful water purification technology that uses a semi-permeable membrane to remove impurities from water. However, a typical RO system is not consisting of the RO membrane alone, but it embodies a series of components to achieve optimal filtration. Here's a brief rundown of these components and their functions.

Pre-filters: RO systems are usually equipped with sediment and carbon pre-filters before the RO membrane to deal with larger particles such as dirt, sand, and rust. This helps protect the membrane from early fouling, thus prolonging its lifespan.

RO Membrane: The crux of the system is the RO membrane. Its semi-permeable layer sieves out microscopic impurities such as dissolved salts and heavy metals while allowing water molecules to pass through.

Pressure Pump: The pump applies pressure to the incoming water so that it gets pushed through the membrane despite the osmotic pressure working against it. It's especially critical in systems dealing with brackish or seawater desalination.

Storage Tank: After being purified, the filtrate water needs to be stored somewhere for later use. That's where the storage tank comes in. It's designed to hold purified water until you're ready to use it.

Post-filter: Post-filters or polishing filters are designed to remove any remaining taste or odor in the water after the RO process before it reaches your tap.

Flow Regulator: This component maintains a regulated wastewater flow to prevent excess water usage and maintain an optimal filtration rate.

Check Valve: The check valve prevents the backward flow of water from the storage tank, protecting the membrane from pressure fluctuations and potential damage.

Automatic Shut-Off Valve: When the storage tank is full, this valve interrupts water flow to the membrane, thus saving water and preventing unnecessary system strain.

Drain Line: The drain line is where the system gets rid of the wastewater, i.e., the water containing all the impurities removed by the RO membrane.

In essence, each component in a RO system has a unique function that complements the others, all working in unison to deliver purified and safe drinking water.

When evaluating a Reverse Osmosis (RO) system's effectiveness, various specifications and parameters come into play. Below, we take a closer look at some of the most significant RO system parameters and what they mean:

System Capacity: RO systems are often rated by their daily water production capacity, measured in gallons per day (GPD). Capacities can range from small under-sink systems of 50 GPD to large-scale industrial systems of thousands of GPD.

Rejection Rate: The system's ability to exclude solutes from the purified water is represented as the Rejection Rate, generally expressed as a percentage. Most RO systems offer a rejection rate of 95-99%, removing a vast majority of the impurities from the water.

Recovery Rate: This parameter represents the percentage of feed water converted into purified water. Higher recovery rates mean less water wastage.

Operating Pressure: Each RO system has an optimal operating pressure range, typically between 50 and 200 psi, which depends on the water source and the quality of the feed water.

TDS Levels: Total Dissolved Solids (TDS) denote the concentration of dissolved substances in your water. A quality RO system should drastically reduce these levels, typically below 10 ppm.

Water Quality: The feed water's quality greatly impacts the RO system's operating parameters. Variables such as pH, hardness, iron content, and the presence of chlorine can affect membrane life and system efficiency.

System Dimensions and Weight: These parameters are critical for determining the installation space required for the RO system.

Membrane Life and Replacement Frequency: An important parameter to evaluate the cost-effectiveness and maintenance requirements of the RO system.

In the end, specific configuration of the RO system will indeed depend on individual needs, water source quality, and desired water quality. Please always refer to the manufacturer's recommendations for best results.

Reverse osmosis (RO) systems are acclaimed for their efficiency and adaptability in water purification, but their advantages go beyond these aspects. Here we explore the benefits and unique characteristics of RO systems:

Superior Filtration: RO systems can effectively filter out a vast majority of contaminants, even down to the smallest particles and ions. Most importantly, they can remove harmful substances such as lead, arsenic, and nitrates that can adversely affect health.

Improved Taste: With nearly all impurities removed, RO-treated water usually has a better taste, eliminating unpleasant odors and tastes caused by chemicals, mineral content, and other dissolved pollutants.

Energy Efficiency: RO systems typically require less energy compared to other forms of desalination or purification techniques. This makes them a more environmentally friendly option, especially for areas of scarce fresh water.

Low Maintenance: Once installed, RO systems don't require considerable maintenance. Regular system check-ups and periodical membrane replacement are the primary upkeep tasks.

Versatility: They're suitable for diverse applications, from under-sink home units to large-scale industrial setups for seawater desalination or wastewater management.

In terms of their uniqueness:

Excellent Selectivity: The heart of an RO system is its semi-permeable membrane, equipped with particularly small pores that allow water molecules to pass through while blocking contaminants. This selectivity is exceptional and a major plot twist in water purification.

Pressure-Dependent Operation: Unlike conventional filters, RO systems use water pressure to facilitate filtration. This counteracts the osmotic pressure of the impure water and makes the filtration possible even against concentration gradients.

Two-Stream Output: An RO system simultaneously produces two outputs – the purified water and the rejected stream containing the removed contaminants. This dual-stream output is unique to advanced membrane filtration processes like RO.

Scalability: The RO technology is very scalable, enabling it to meet a vast range of water treatment sizes without losing filtration quality or efficiency.

In conclusion, while RO systems may not be the be-all and end-all solution in every circumstance, they offer an efficient and reliable way to process water in many applications, thanks to their advantages and unique characteristics.

Maintaining a reverse osmosis (RO) system is essential for ensuring its longevity, efficiency, and effective performance. Here are several key aspects you need to consider when it comes to RO system maintenance:

Frequent Inspection: Regularly inspecting the RO system helps detect leaks, pressure issues, or other signs of malfunction. Often, catching and rectifying a small issue can prevent more significant, costlier problems down the line.

Filter Change: Pre-filters and post-filters protect the RO membrane from particulate matter, chlorine, and other potentially harmful substances. Regular replacement of these filters (typically every 6-12 months) is necessary for effective operation.

Membrane Replacement: The core element, the semi-permeable membrane, usually needs to be replaced every 2-3 years, depending on water quality and usage. An under-performing membrane can drastically decrease water quality.

System Sanitization: Sanitizing the entire system, usually annually, is an often-overlooked aspect of maintenance. This process helps clean the system, removing any potential bacterial or algae buildup.

Water Pressure and Quality Monitoring: Periodically recording system pressure and water quality can be a good indication of system performance. Variations from normal conditions might suggest filter or membrane problems.

Professional Servicing: For larger or more sophisticated systems, professional maintenance might be necessary. Trained technicians can complete comprehensive system checks, maintenance, and troubleshooting.

Reading the Manual: Each RO system can come with its unique quirks and maintenance recommendations. Always refer to the system's manual for manufacturer-specific advice and precautions.

In summary, maintaining an RO system is a combination of regular inspections, replacing filters and membranes as necessary, comprehensive sanitization, and seeking professional help when needed. By respecting these guidelines, RO systems can deliver efficient and reliable service for many years.

Reverse Osmosis (RO) systems stand out as versatile and efficient solutions for water treatment, used across a spectrum of industries. Here are some key sectors where RO technology proves invaluable:

Drinking Water Purification: RO systems provide high-quality drinking water in residential, office, and public spaces. They deliver water free from harmful contaminants, ensuring safety and better taste.

Municipal Water Treatment: Many cities incorporate RO technology in water treatment plants to purify municipal water supplies, especially in areas where water sources may be polluted or scarce.

Food & Beverage Industry: RO technology helps maintain product quality in the food and beverage industry, removing impurities that might affect taste, color, or shelf-life of products.

Pharmaceutical Industry: Producing pure water for various pharmaceutical processes, including formulation, cleaning, and quality control, is another significant application of RO systems.

Agriculture: In farming and horticulture, RO systems can treat water to meet specific plant needs, removing harmful salts or adjusting mineral content to optimally support crop growth.

Aquariums & Aquaculture: Aquariums and fish farms use RO systems to make suitable environments for aquatic life, maintaining species-specific water conditions.

Electronics Manufacturing: The production of semiconductors and other electronics requires ultrapure water. RO systems provide a key part of this water purification process.

Boiler Feed and Cooling Water: Industries using boilers and cooling systems need to prevent scaling and corrosion problems. Treating water with RO systems helps achieve this, prolonging equipment life.

Power Generation: In power plants, especially in thermal and nuclear plants, RO systems enhance the quality of water used in steam generation, leading to higher efficiency.

Desalination: RO systems are ideal for larger scale sea or brackish water desalination, providing fresh water in water-scarce regions.

In summary, the application of reverse osmosis technology spans various sectors where water quality plays a critical role. From enhancing our drinking water to supporting industrial efficiency, the versatility of RO systems is clear.

Reverse Osmosis (RO) systems play a significant role in both environmental stewardship and social well-being. Here's a look at the impact:

Environmental Impact:

Water Conservation: RO systems effectively purify contaminated water sources, preventing wastage of potentially useful water. They can treat both industrial waste-water and naturally polluted water sources.

Reduced Chemical Usage: Unlike many other water treatment methods, RO systems do not require harmful chemicals. This reduces the environmental impact linked to chemical production, usage, and disposal.

Energy Efficiency: Modern RO systems are becoming increasingly energy-efficient, reducing the carbon footprint associated with their operation.

Desalination: In regions where freshwater sources are limited, desalination of seawater using RO systems provides a valuable resource while preserving the natural freshwater resources.

Social Impact:

Public Health: By producing clean, contaminant-free water, RO systems have a direct positive impact on public health. They reduce the risk of water-borne illnesses and contribute to better overall health.

Economic Improvement: Access to clean water can drive economic improvement, especially in underserved regions. Applications are not only limited to drinking water but extend to agricultural, industrial, and commercial usage.

Education and Awareness: The implementation of RO systems, especially in schools and community centers, provides opportunities for education and awareness about water conservation and hygiene.

Emergency Relief: Portable RO units can be used for water purification in disaster-struck areas, reducing the impact of such events on affected communities.

In conclusion, reverse osmosis systems are not just tools for water purification. They contribute meaningfully to environmental sustainability and societal well-being. As technology continues to advance, their importance is only set to increase.