Reverse Osmosis (RO) Membranes are an integral part of many water purification systems, known for their unique ability to remove a wide array of water impurities and contaminants. Employing the principle of reverse osmosis, these membranes utilize pressure to force water molecules through a semi-permeable surface, a process directly opposing natural osmosis.

Their selective permeability permits only water molecules to pass through, ensuring efficient separation and removal of undesirable substances, including bacteria, viruses, heavy metals, and dissolved salts. Noteworthy for their durability, RO Membranes, when properly maintained, function effectively for an extended period, typically from 2 to 5 years. This endurance makes them a highly reliable component of water treatment systems utilized across various settings.

Whether employed in residential environments for purifying drinking water or in industrial setups such as food and beverage production, pharmaceuticals, and wastewater treatment, the versatile application of RO Membranes is truly impressive.

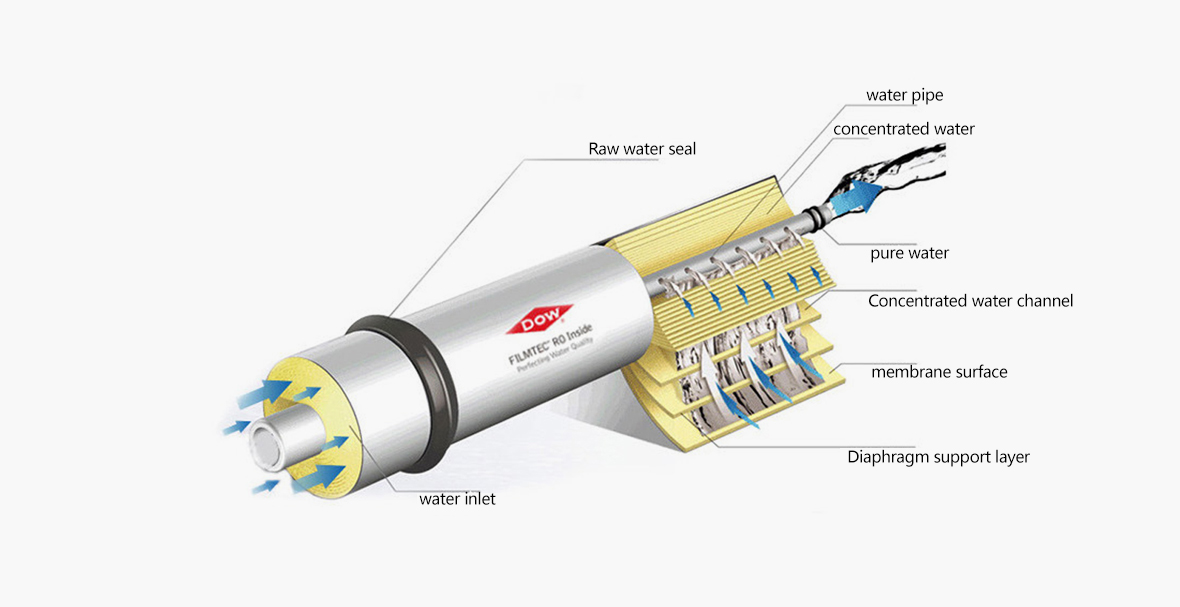

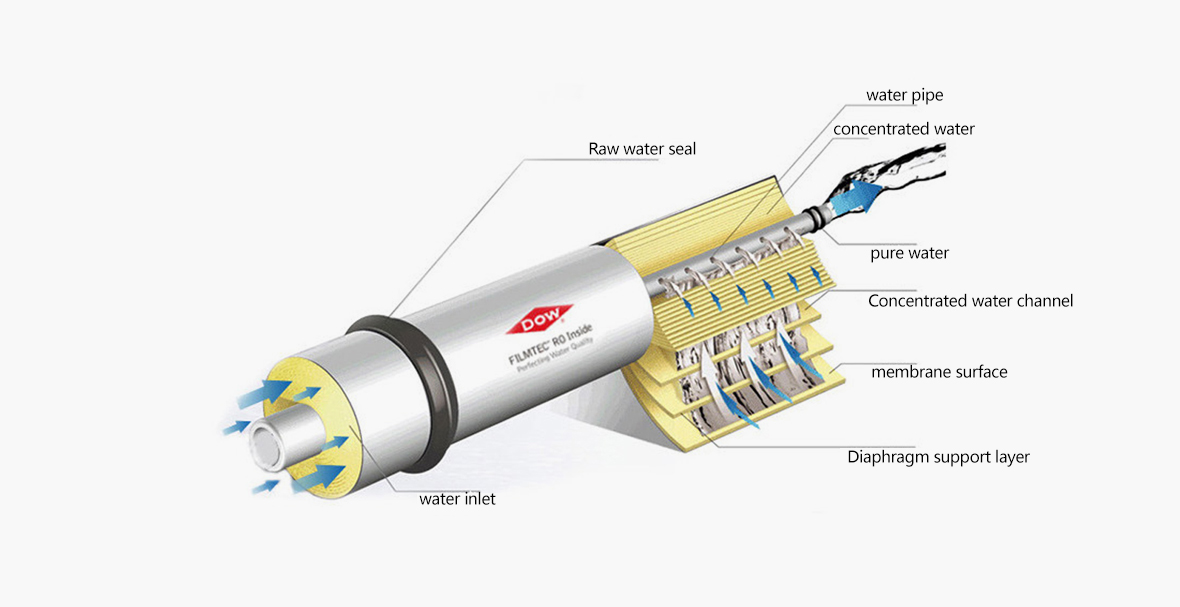

Their operational mechanism involves pressurized feed water being directed through the membrane. The fine pores of the membrane allow only the water molecules to pass, holding back the contaminants which are subsequently flushed out of the system. The filtered water, commonly referred to as product or permeate water, is then stored for use.

Ensuring optimal performance of an RO Membrane mainly requires regular inspection and routine cleaning, along with the mitigation of any potential scaling or fouling. Following the manufacturer's guidelines, the membrane needs to be replaced entirely should there be a noticeable decline in the purified water's quality.

While RO Membranes significantly contribute to ensuring water purity, it's also essential to consider the environmental implications. The by-product of this process, a wastewater or brine stream resulting from the concentrated impurities left behind, mandates appropriate disposal means.

All things considered, Reverse Osmosis (RO) Membranes represent a significant advancement in water treatment technologies. Their ability to provide high-quality, purified water across varying areas of application plays a fundamental role in ensuring both human health and environmental sustainability.

Reverse Osmosis (RO) is a special type of filtration process, primarily used for water purification. It involves using a semi-permeable RO membrane under high pressure to separate impurities from water.

The working principle of an RO membrane is fairly straightforward and hinges on the concept of osmosis. Osmosis is a natural process where liquid molecules move from a low concentration solution to a high concentration solution through a semi-permeable membrane to establish equilibrium. However, in reverse osmosis, as the name suggests, this process is reversed.

RO systems utilize a high-pressure pump to increase the pressure on the salt side of the membrane, forcing water across the membrane while leaving the majority of dissolved salts behind. The pressurized conditions essentially compel the water to move from a region of greater solute concentration (contaminated water side) to a region of lower solute concentration (filtered water side). This is contrary to the natural osmotic flow and hence the term, reverse osmosis.

The water that makes it through the RO membrane is deemed purified and is then ready for consumption or use. This water, often referred to as permeate, is largely free of impurities and contaminants, having been stripped of substances like salts, bacteria, viruses, and heavy metals. Meanwhile, the impurities that didn't pass through the RO membrane are flushed out as waste, also known as concentrate or brine.

Through this principle, RO membranes offer an effective way to purify water down to microscopic levels, making them an essential component in various water treatment systems. They enable the production of safe, high-quality water for numerous uses, from domestic consumption through to industrial processes.

In summary, the working principle of RO membranes leverages pressure and the selective nature of the membrane to achieve a high level of water purity, marking a significant advancement in water treatment technology and contributing to health and environmental sustainability.

Composition and Function of Reverse Osmosis (RO) Membranes: Original English Content

Reverse Osmosis (RO) Membranes are a central element in the water purification process. Their composition and the intricate functionality they perform contribute significantly to their effectiveness.

Composition of RO Membranes:

RO membranes are made from a semi-permeable polymeric material. The membrane's composition mainly consists of three layers:

The top layer is a thin Polyamide (PA) film, which serves as the active or rejection layer responsible for separating impurities.

Below the rejection layer is a Polysulfone (PS) layer also known as the support layer, which provides structural firmness for the top layer.

The third layer, also the bottom layer, is a fabric support web. This layer primarily serves to give the overall RO membrane its strength and durability.

Function of RO Membranes:

RO membranes serve as a barrier in the filtration process, allowing the selective passage of substances. They are designed to allow only water molecules to pass through while blocking impurities.

The primary function of an RO membrane is to filter out undesirable substances from the water. This includes various types of contaminants such as dissolved salts, bacteria, viruses, heavy metals, and other microorganisms.

Apart from serving as an effective filter, the RO membrane also plays a crucial role in maintaining the efficiency of the entire RO system. It can resist damage from chemical reactions or physical strain, thereby improving the durability and longevity of the system.

In a nutshell, the composition and function of Reverse Osmosis (RO) Membranes play a critical role in the purification of water. These membranes leverage advanced technology to ensure the production of safe, high-quality water for a wide range of applications, contributing significantly to environmental sustainability and public health.

An RO (Reverse Osmosis) Membrane plays a central role in an RO System. Its key function is to purify water by segregating impurities on a microscopic level.

The entire RO system primarily consists of a pre-filtration stage, an RO membrane stage, and a post-filtration stage. The RO membrane lies at the heart of this system.

In the pre-filtration stage, larger contaminants are filtered out. This preserves the RO membrane's integrity by preventing damaging substances from reaching it.

The heart of the RO system - the RO Membrane stage – is where the most critical purification occurs. The pressurized water is forced through the semi-permeable RO membrane, with water molecules being small enough to pass through the minute pores of the membrane. At the same time, harmful contaminants, including salts, bacteria, and other microorganisms, are left behind because their molecular structure is too large for the pores of the RO membrane.

In the post-filtration or ‘polishing’ stage, final cleaning as a safety precaution takes place. This ensures that any potential impurities that may have made it past the membrane are thoroughly removed.

Hence, within the RO system, the RO membrane is the critical component responsible for the actual intended purification. It significantly reduces a variety of contaminants, such as total dissolved solids (TDS), heavy metals, viruses, and bacteria, delivering safe, clean drinkable water.

Not only that, the RO membrane contributes to the system’s efficiency. With proper maintenance, an RO membrane can last several years, conferring long-term cost-effectiveness and reliability to the RO system.

In a nutshell, the RO membrane is the functional heart of the RO system, responsible for the major purifying action, and maintaining the overall efficiency and productivity of the system.

The specifications and parameters of an RO (Reverse Osmosis) membrane can vary based on the manufacturer, the application, and the design of the RO system. Let's discuss some of the key features that are typically seen in RO membranes.

1. Material: Most RO membranes are made from a type of plastic known as polyamide. This material is durable, chemically resistant, and has excellent water permeability properties. Some RO membranes may also use polysulfone or cellulose triacetate.

2. Size: The size of RO membranes can vary dramatically based on the application. For home systems, the average size is generally around 10 to 50 square feet. Commercial and industrial applications can require much larger RO membranes, which can be as large as 300 to 400 square feet.

3. Operating Pressure: The operating pressure for RO membranes is typically between 150 to 600 psi (pounds per square inch). The actual required pressure will depend on the type of feedwater and the desired level of water purity.

4. Flow Rate: The flow rate is how much water can pass through the RO membrane in a given time. It's usually expressed in gallons per day (GPD). RO membranes can range from 50 GPD for small home systems to over 1,000 GPD for commercial applications.

5. Rejection Rate: One of the most critical parameters of an RO membrane is its rejection rate. This is the percentage of contaminants that the membrane removes from water. Most RO membranes have a rejection rate of over 95%-99%, depending on the specific contaminants.

6. Lifespan: The lifespan of an RO membrane depends on its quality, the characteristics of the feedwater, and how well the system is maintained. Typically, a residential RO membrane can last 2-3 years, while a commercial RO membrane can last 3-7 years.

7. Temperature and pH range: RO membranes typically operate at temperatures between 20°C (68°F) and 45°C (113°F), with an ideal pH range between 3-10.

These are some of the primary specifications and parameters of an RO membrane. However, it's essential to know that these can vary dependant on the specific use case of the membrane, and always to check the manufacturer's information for any specific model.

1. Superior Filtration: RO membranes provide one of the highest levels of filtration available, capable of removing up to 99% of all dissolved solids, organic particles, and bacteria from the water. This extreme level of filtration ensures that only safe, clean water is produced.

2. Versatility: RO membranes can work effectively with a variety of water sources, including municipal, well, and brackish water. They're even capable of purifying seawater, although this process requires significantly more energy.

3. Economical: Although the initial investment for an RO system can be high, the cost per gallon of filtered water is comparatively low. Additionally, an RO membrane has an average lifespan of 2-3 years (residential) to 3-7 years (commercial), which can make it a cost-effective solution in the long run.

4. Less Maintenance: Once an RO system is properly installed and set up, it requires relatively minimal maintenance. Regular maintenance mainly includes periodic membrane replacement and system cleaning.

5. Removes a Wide Array of Contaminants: RO membranes are effective in removing a wide range of harmful substances, including lead, mercury, chlorine, pharmaceuticals, pesticides, and even microorganisms like bacteria and viruses.

6. Enhances Taste: By removing a significant portion of the contaminants present in the water, RO membranes also contribute to improving the taste, odor, and color of the water.

7. Environmentally Friendly: RO systems are more eco-friendly compared to bottled water as they reduce plastic waste. Moreover, newer RO systems have improved water efficiencies to decrease the overall amount of wastewater generated.

To sum up, RO membranes offer superior filtration resulting in purified drinking water, versatility in handling different water sources, economic advantages over time, and eco-friendliness by reducing dependence on bottled water. It's these numerous benefits that make RO systems a popular choice for water purification needs, whether it's for residential or commercial use.

Applications and Industries Using Reverse Osmosis (RO) Membranes:

1. Water Treatment Industry: The most common application of RO membranes is in water treatment plants where they are used for the purification of municipal and industrial wastewater, generation of potable water and desalination of seawater.

2. Food and Beverage Industry: In the food and beverage industry, RO membranes are used to purify water that is used in processes such as cooking, cleaning, and ingredient mixing. They also make the water used in beverages, like bottled water, soft drinks, and beer, cleaner and better-tasting.

3. Pharmaceutical Industry: RO membranes are used to produce ultrapure water needed for making pharmaceutical products. This ultrapure water is used in the formulation of the pharmaceutical products and also for cleaning the equipment used in the production process.

4. Power Generation Industry: In power plants, RO membranes are used to produce demineralized water that is used in boiler feed water to prevent scaling and corrosion, which can hamper the efficiency of power generation.

5. Semiconductor Manufacturing: In this industry, ultrapure water is required for washing silicon wafers and other components, which is produced through RO systems.

6. Agriculture and Aquaculture: RO systems are used to purify water used in irrigation and also to generate fresh water from brackish water in fish farming.

7. Dialysis Units: In clinical applications, RO membranes are used in renal dialysis units. They purify the water that is used in the dialysis machines, which is critical for patient safety.

8. Automotive Industry: RO purified water is used in numerous automotive processes such as surface treatment, paint preparation, and final rinse stages to ensure high-quality finishes without mineral spotting.

These applications underscore the widespread utility of RO membranes across different industries, where the production of high-quality water is often fundamental to operational success and product quality.

Installation of RO Membranes:

Location Selection: Choose a suitable location for the RO system that provides easy access for maintenance. It should be close to a water source and drain, and ideally, near the point of use.

Prep the System: Unpack the RO system and check to ensure all parts are included. This typically involves an RO membrane, pre-and-post filters, and a storage tank.

Connect to Water Source: The RO system should be hooked up to a cold water line. A saddle valve is commonly used to tap into water supply.

Install Filters and Membrane: Install the pre-filters and the RO membrane according to the instructions provided by the manufacturer.

Connect the Drain: The RO system will also need to be connected to a drain to get rid of wastewater.

Check for Leaks: Once everything is connected, turn on the water supply and inspect the system for leaks. If no leaks are present, you can proceed by turning on the system.

Maintenance of RO Membranes:

Replace Pre-and-Post Filters: Pre-and-post filters protect the RO membrane and enhance the performance of the system. As such, they should be replaced every 6 to 12 months, depending on the quality of your water and usage.

Change the RO Membrane: Typical residential RO membranes need replacing every 2-3 years, but this may vary depending upon the condition of your feed water and the pattern of usage.

System Sanitization and Cleaning: On an annual basis, carry out a system sanitization and cleaning process. This may involve running a solution (usually chlorine or a similar sanitizing agent) through the system to eliminate any bacteria or bio-film build-up.

Regular Inspections: Conduct regular inspections of the entire RO system to ensure all components are in good working order and to check for any leaks.

Ensuring correct installation and maintenance of your RO membrane will prolong the filter's lifespan, maintain optimal performance, and continue to provide safe and pure water. Remember to always consult with the manufacturer's specific guidelines for installation and maintenance to ensure the best care for your system.

Environmental Impact:

Water Conservation: RO membranes are capable of producing highly purified water from sources that may otherwise be unsuitable for use, such as seawater or polluted rivers. This helps in conserving freshwater resources by expanding fresh water availability.

Reduced Dependence on Bottled Water: With the ability to purify tap water effectively, RO systems can reduce the demand for bottled water, thereby reducing plastic waste associated with it.

Waste Management: However, RO systems do produce a certain amount of wastewater. Modern advances in RO technology are reducing this wastewater output, making them more efficient and eco-friendly.

Societal Influence:

Health benefits: Clean drinking water is a fundamental human need. Its availability directly influences a person's health. RO systems providing high quality water can thus have a significant societal impact in terms of improved health outcomes.

Promoting Self-Sufficiency: RO systems offer individuals and communities the ability to produce their own purified water, reducing dependence on external water supplies, and promoting self-sufficiency.

Economic Opportunities: The manufacture, installation, and maintenance of RO systems create numerous jobs and contribute to economic growth.

Disaster Assistance: In the aftermath of natural disasters, RO systems can play a critical role, providing clean drinking water when traditional supplies may be disrupted.

In conclusion, RO membranes are not only an effective water purification solution but also contribute positively to environmental protection and societal well-being. However, continuous efforts should be made to address their environmental drawbacks, like wastewater production, in order to further enhance their sustainability.