Every industry demands apparatus that are not just efficient but also reliable, durable, and user-friendly. When it's about filtration requirements, the LYC Coalescence Dehydration Oil Filter stands as your unmatched solution.

The LYC Coalescence Dehydration Oil Filter presents an ingenious blend of exceptional filtration and exceptional dehydration. It breaks the conventional bounds of filtration with its high-efficiency filter system, important for large filtration tasks and enhancing your operational efficiency.

Our filter doesn't discriminate with the oil type. Be it turbine oil, transformer oil, or hydraulic oil, it masterfully handles the purification process for all.

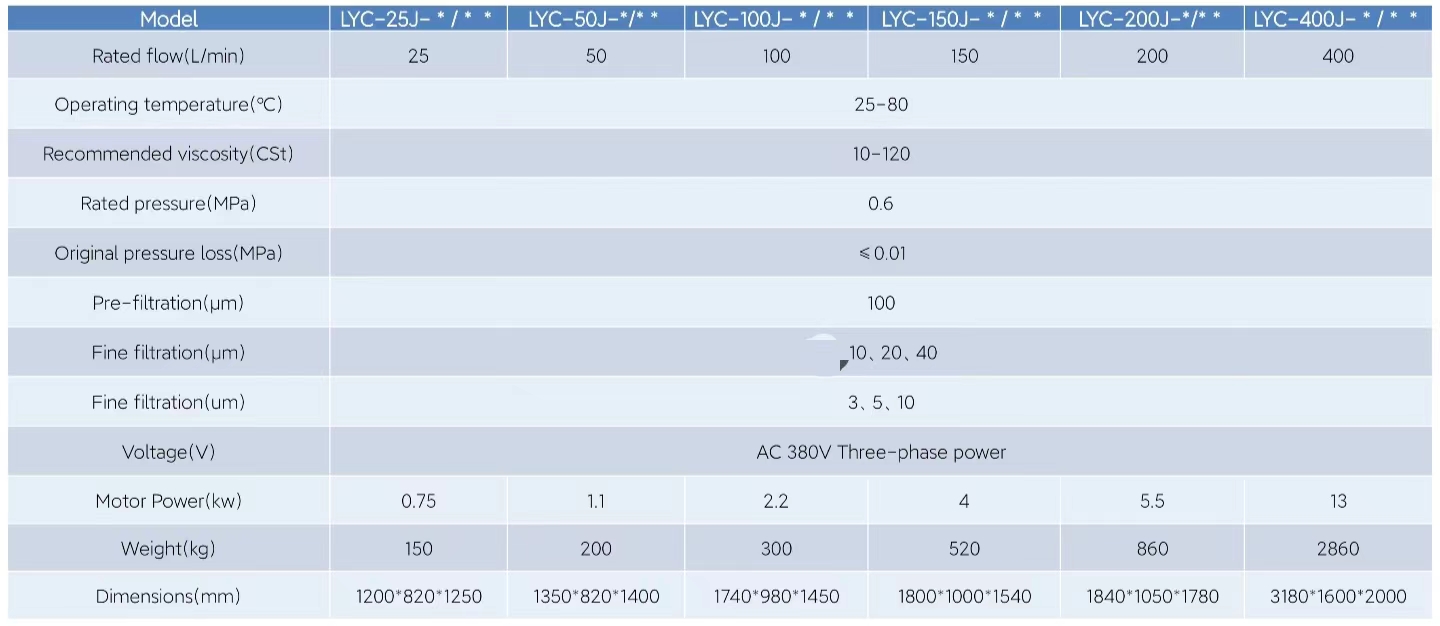

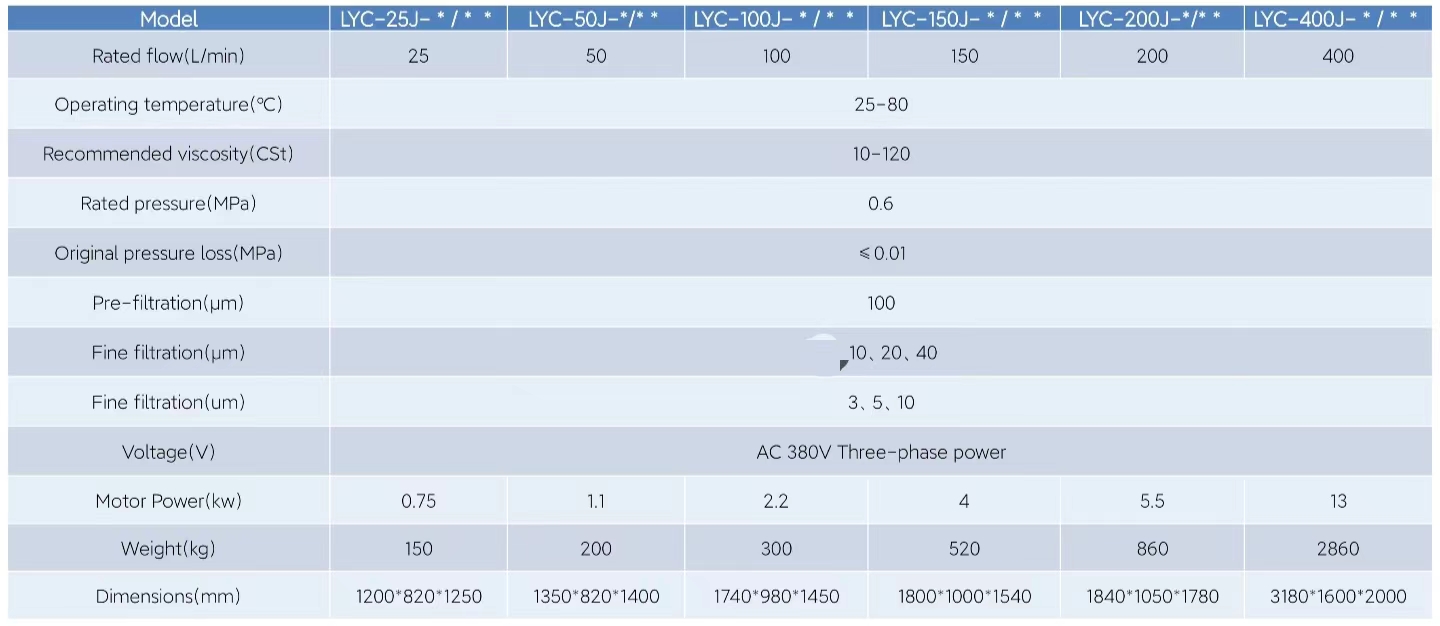

The LYC Coalescence Dehydration Oil Filter operates efficiently within a temperature range of 25-80°C, accommodating oil viscosities between 10-120 CSt. With a rated pressure of 0.6 Mpa and minimum original pressure loss of ≤0.1 Mpa, it ensures optimal operation without compromising performance.

In conclusion, this filter is an epitome of optimal functionality, durability, and reliability, all packed in one. The LYC Coalescence Dehydration Oil Filter is more than just an equipment; it is an investment that guarantees unmatched filtration and dehydration for years to come.

Primary Features:

High-efficiency Media Filter: The LYC Coalescence Dehydration Oil Filter is designed with a superior filter system. The high-efficiency media filter provides effective purification, effortlessly removing impurities from the oil.

Large Filtration Area: The design boasts a generously expansive filtration area. Such a feature is instrumental in optimizing the filtration process, accommodating larger quantities of oil and reducing operational time.

Five-Stage Filtration: The filter utilizes an advanced, meticulous five-stage filtration process. This ensures the thorough removal of contaminants and enhances the quality of purified oil.

Versatility: Moreover, this filter doesn't discriminate between oil types. Be it hydraulic oil, transformer oil, or turbine oil, it ensures perfect purification across all categories.

Advantages:

Exceptional Dehydration Performance: The prime advantage of the LYC Coalescence Dehydration Oil Filter is its exceptional dehydration performance, efficiently eradicating water from oils.

Operational Efficiency: With an intelligently designed filtration system and large filtration area, this filter offers significant improvements in operational efficiency, which could result in increased productivity.

Versatility and Broad Application: This filter's versatility is truly unparalleled, being suitable for various oil types and industrial applications.

Durable Construction: Finally, its robust construction ensures the filter's long lifespan, providing persistent unbeatable performance and and minimizing maintenance, ultimately leading to cost savings over the course of its use.

In conclusion, the LYC Coalescence Dehydration Oil Filter proves to be a sound investment, promising outstanding filtration, superior dehydration, and expansive applicability wrapped in durable construction. This excellent tool is the ultimate partner for all your industrial filtration needs.

The Unique Industry Advantages of LYC Coalescence Dehydration Oil Filter

In the ever-evolving landscape of industrial filtration, finding the right equipment for your operations can be a challenging task. However, the LYC Coalescence Dehydration Oil Filter truly emerges as a class apart and here's why.

Unrivaled Filtration and Dehydration: The LYC filter boasts exceptional filtration and dehydration capabilities. Its intricate five-stage filtration process, coupled with superior dehydrating performance, ensures that oil is purified to optimum levels, giving the LYC filter an exceptional competitive edge.

Operational Efficiency: Time is of the essence in industrial applications. With its large filtration area and advanced filtering system, the LYC filter significantly improves operational efficiency. It demonstrates a decreased filtration time without compromising on the quality of output, contributing to its industry prominence.

Versatility: The filter's multi-faceted appeal lies in its versatility. capable of handling various oil types—turbine oil, transformer oil, hydraulic oil, and more, it eliminates the need for multiple filters in the workplace, proving itself to be a cost-effective, all-in-one solution.

Durability: Let's not forget the robust construction of the LYC filter that guarantees longevity. Its design is durable, ensuring sustained high-level performance over extended periods. This promises minimal maintenance costs and maximum return on investment, making it a leading choice for industries.

Persistent Innovation: LYC constantly innovates and improves upon their product designs. Their forward thinking approach and commitment to incorporating the latest in filtration technology keeps them at the forefront of the industry.

Environmental Consideration: The LYC Filter showcases enhanced environmental consideration. With efficient filtration, it helps cut down on wastage, promoting more responsible and greener industrial practices.

In conclusion, the LYC Coalescence Dehydration Oil Filter has positioned itself as the go-to choice for diverse industries due to its excellent filtration and dehydration, operational proficiency, versatility, and durable construction. Coupled with the company's diligent commitment to innovation and eco-friendly practices, it's no wonder it stands as an unmatched filtration option in the market.

A Detailed Look at the Technical Specifications of LYC Coalescence Dehydration Oil Filter

Optimum Operating Temperature Range: The LYC filter adeptly handles a broad range of temperatures, making it ideal for various operating conditions.

Accommodated Oil Viscosities: Whether it's low or high viscosity oil, the LYC filter can accommodate. Its intelligent design means it can purify oil of varying viscosities with equal efficiency, further enhancing its versatility.

Rated Pressure and Original Pressure Loss: The LYC filter is designed to operate optimally under a specific pressure range. Its initial pressure loss stays minimal, proving that it's capable of excellent performance even under demanding operations.

Filtration Precision: The LYC filter takes pride in delivering highly precised filtration results. Regardless of the level of impurities, it can filter to a high degree of precision, ensuring an outstanding output quality.

Flow Rate: Despite its intricate filtration and dehydration process, the LYC filter boasts an impressive flow rate. It can process a substantial volume of oil in a given timeframe, contributing to its high operational efficiency.

Dimensions and Weight: Its design principles maintain a perfect balance between functionality and size. The dimensions and weight of the LYC filter are carefully calibrated to provide superior performance while maintaining practicality and ease of use.

Material Construction: The LYC filter is constructed from robust, high-quality materials. This ensures not just optimal performance but also longevity and resistance to wear and tear.

In conclusion, the superior technical specifications of the LYC Coalescence Dehydration Oil Filter facilitate its outstanding filtration and dehydration performance across various conditions and oil types. Combining versatility, effectiveness, and durability, it stands as the epitome of a reliable, high-performing industrial filtration tool.

Understanding The Working Principle of LYC Coalescence Dehydration Oil Filter

The LYC Coalescence Dehydration Oil Filter operates on the premise of coalescence, a process where small droplets of oil are united to form larger droplets in order to be effectively separated from water or other contaminants. Here is how it takes place:

The First Stage - Filtration: When oil first enters the system, the initial filtration stage takes place. This is where large particulates and impurities are removed using a preliminary filter.

The Second Stage - Coalescing: The second stage initiates the actual process of coalescence. Tiny oil droplets pass through a coalescing filter, which is designed to promote the merging of these small droplets, leading to the formation of larger oil globules.

The Third Stage - Separation: Once the oil has passed through the coalescing filter and larger droplets have been formed, the third stage—separation, comes into play. Here, the larger oil droplets, due to the difference in specific gravity, will rise to the top while the water droplets settle at the bottom.

The Fourth Stage - Dehydration: Sent to a dehydration chamber, the heavier water molecules remain at the bottom of the chamber while the lighter oil floats on the top. That oil is then carefully drawn off from the surface, producing oil with significantly reduced water content.

The Final Stage - Polishing: The final stage of operation is the polishing process. The oil, now devoid of water or solid contaminant, is passed through a final, micro filter to remove any remaining small impurities, resulting in the highest quality purified oil.

Needless to say, the LYC Coalescence Dehydration Oil Filter operates through a sophisticated multi-stage process to ensure the highest quality of oil purification. Whether it's removing impurities or dehydrating oil, its commitment to delivering the purest oil is certainly unparalleled within the industry.

Core Applications of the LYC Coalescence Dehydration Oil Filter

Power Generation Industry: In the power generating sector, this oil filter is primarily used for processing turbine oils. It helps to initiate a smooth turbine operation by reducing the water and impurity content in the lubricants, thus providing an efficient power generation process.

Industrial Manufacturing: The LYC filter plays a crucial role in various manufacturing processes where it's used to purify hydraulic oils, lubricating oils, and coolants. Thus, it contributes to the longevity of the machinery, increased efficiency, and reduced maintenance costs.

Oil & Gas Industry: Impurities and water in the oil can seriously affect the quality and safety in the oil & gas industry. As such, the LYC filter comes in to provide an optimal solution to filter and purify these oils, thereby improving overall operational efficiency.

Aviation Industry: For the aviation field, this filter is especially important. It ensures maximum efficiency in the operation of aircraft and support equipment by purifying the oil used in hydraulics and other vital mechanisms.

Maritime Industry: As a vital component of the shipping industry, the LYC oil filter assists in the smooth operation of marine machinery. It decontaminates the oil used in various marine applications, guaranteeing better onboard machinery performance.

Automotive Industry: The LYC filter can also be used for filtration of engine oils in vehicles. It removes impurities and water from the oil, contributing to the better performance and longevity of the automobile's engine.

In conclusion, the adaptability of the LYC Coalescence Dehydration Oil Filter assures its role in numerous industries. Whether the objective is to ensure smooth construction processes, safe oil & gas operations, or efficient power generation, its contribution cannot be undermined. In fact, its utility extends to any industry where oil purity is of cardinal importance.

Long-Term Use and Maintenance Guide for the LYC Coalescence Dehydration Oil Filter

Regular Inspections: Making a habit of periodically checking the filtration system aids in identifying any irregularities or abnormalities at initial stages and taking prompt corrective measures.

Filter Replacement: Carry out regular inspections of the filter element and replace it in a timely manner. Prolonged operation with a clogged filter will affect the purifying effect and the operational efficiency.

System Cleaning: Maintaining cleanliness is imperative to the machine's performance. Ensure that the unit, particularly the oil tank and the filter, is cleaned regularly to prevent build-up of impurities and contaminants.

Examination of Seals and Gaskets: To prevent leakage and ensure efficient operation, it is necessary to check and test the seals and gaskets regularly. Replace any that show signs of wear and tear immediately.

Monitoring Oil Contamination Levels: Regular monitoring of oil contamination levels can provide a clearer picture of the oil filter's performance. If contamination levels are not reduced as expected, it may signify a problem requiring attention.

Preventing Overheating: Overheating could impair the filtration process and damage the filter elements. It is crucial to maintain the appropriate operating temperature and provide ample cooling.

Professional Maintenance Check: In addition to the routine checks and measures, schedule a comprehensive inspection by a trained professional at regular intervals. Their experienced eye can help diagnose and rectify issues that may have been overlooked.

Following Manufacturer's Guidelines: Always adhere to the guidelines and instructions provided by the manufacturer when it comes to maintenance and operation.

Safety Measures: When carrying out maintenance or inspection, please ensure safety measures such as wearing proper protective equipment and isolating the power supply.

In conclusion, efficient and effective maintenance is the key to the longevity and performance of the LYC Coalescence Dehydration Oil Filter. By following this guide, you can ensure that your LYC oil filter remains in optimal working condition while prolonging its service life.

Ensuring Performance and Durability: The LYC Coalescence Dehydration Oil Filter

Performance Assurance:

The performance of the LYC Coalescence Dehydration Oil Filter is backed by its state-of-the-art engineering design and high-quality material usage. The filter achieves a high level of oil purification by applying a multi-stage filtration process, effectively removing impurities and water content.

By ensuring that the oil passing through it is thoroughly cleansed, this filter piece promotes optimal operation of machinery and equipment that it services. The superior performance of the LYC filter hence contributes to enhanced efficiency, reduction of wear and tear, and overall longevity of the machinery.

Durability Confidence:

The durability of the LYC Coalescence Dehydration Oil Filter is ensured through top-notch manufacturing standards and robust materials used in its construction. Made to withstand strenuous operating conditions, the filter is able to provide reliable and long-lasting service.

Certain features contribute to its durability. The filter elements are designed for extended service life and the housing materials can withstand environmental changes. Furthermore, seals and gaskets are made to prevent leakage and to endure the stress of operation, promoting the overall durability.

In maintenance, the filter's design allows for easy replacement of parts and cleaning. This, paired with adherence to prescribed maintenance schedules and guidelines, will ensure that the LYC filter continues to operate at peak performance over extended periods of use.

In conclusion, the guarantee of the LYC Coalescence Dehydration Oil Filter's performance and durability is a reflection of the committed engineering, superior manufacturing standards, and rigorous quality control processes that stand behind its name. The brand's dedication to delivering a product that meets and exceeds customer expectations ensures that the LYC filter is a top choice for any industry requiring effective oil purification and filtration.