Product Description

3M Company, initially incorporated in 1902 as Minnesota Mining and Manufacturing Company, has transformed over the century into a diverse multinational conglomerate that leverages innovation and technology. Recognized globally for its diligent research, development prowess, and synergy of technology across different sectors, 3M has carved out a significant presence in the domain of filtration tech. Its unyielding commitment to quality and efficiency sets benchmarks in the industry and makes it a trusted name when it comes to reliable filtration solutions.

In the industrial arena, high flow filters have emerged as a critical cog in operation machinery. These are ingeniously designed to tackle high volume applications, a rampant necessity in today's large-scale industrial operations. They form the lifeblood of numerous manufacturing processes, sewage treatments, oil and gas operations, and even the food and beverage industry.

One of 3M's remarkable innovations in this area is the 3M High Flow Series Filter Cartridges. These cartridges make a standout through their ability to deliver robust filtration at much higher flow rates than standard filters in the market. They encapsulate 3M's tradition of delivering efficiency and durability, offering enhanced contaminant capture and longevity. Consequently, they lead to less downtime, lesser change-outs, and heightened productivity.

In essence, the 3M High Flow Series Filter Cartridges are not merely a product offering. They represent a testament to 3M's approach to persistent innovation, a stride towards effectuating more efficient, sustainable industrial filtration. True to 3M's credo of applying science to life, this series signifies a stride in bettering our lives by transforming our industries.

technical design

The 3M High Flow Filter Series Cartridges are meticulously engineered to encompass a blend of innovative features, presenting a dynamic balance between advanced design and sophisticated technology.

At the heart of their construction is a coreless, cylindrical design which leaves behind the need for a solid core, common in traditional filters. This innovative design reduces unnecessary waste and bestows the filter with enhanced durability and structural integrity while also enabling easier handling due to the resulting weight reduction.

Another striking feature is the high surface area facilitated by the use of pleated media. This style bypasses the limitations possessed by rolled or wound media, used in orthodox filters. By incorporating pleated media, the cartridges can accommodate a larger volume of contaminants over the same duration, thereby improving overall efficiency. Further, the higher surface area culminates in an efficient dispersion of particles, leading to a purer end product.

Acknowledging the technological intricacies, the 3M High Flow Series Filter Cartridges incorporate a proprietary polypropylene blend as the chosen filtration medium. The filter media's peculiar composition enables superior particle retention, culminating in a high degree of filtration efficacy. The incorporation of the polypropylene media blend, coupled with thermally bonded construction, prohibits any fiber migration, securing the integrity of the filtrate.

Among other noteworthy features are the remarkable flow rates these cartridges can handle. Having been engineered to endure high-volume industrial operations, the cartridges can deliver volumetric flow rates up to an impressive 500 gallons per minute, far beyond conventional filters.

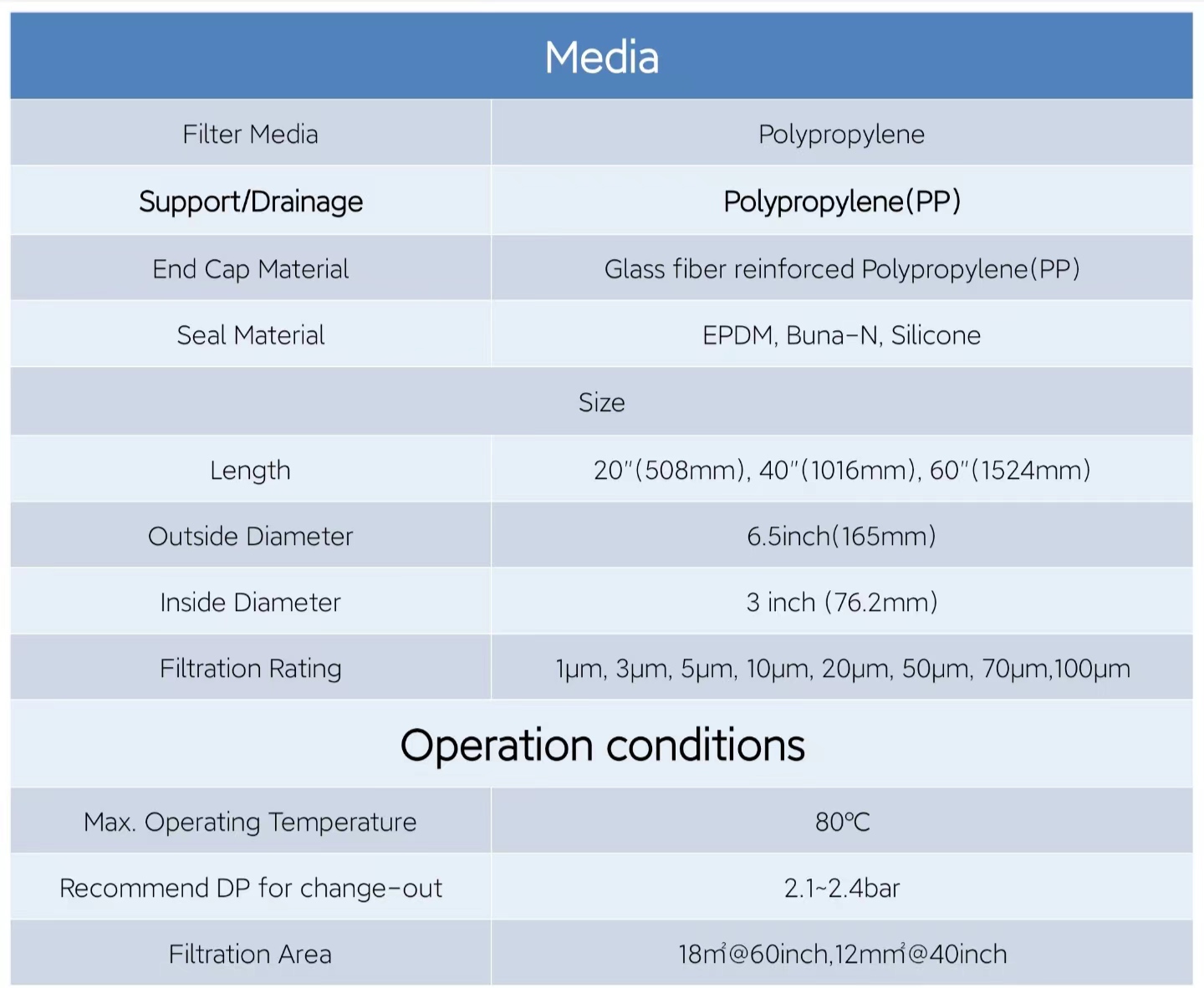

Technical parameters

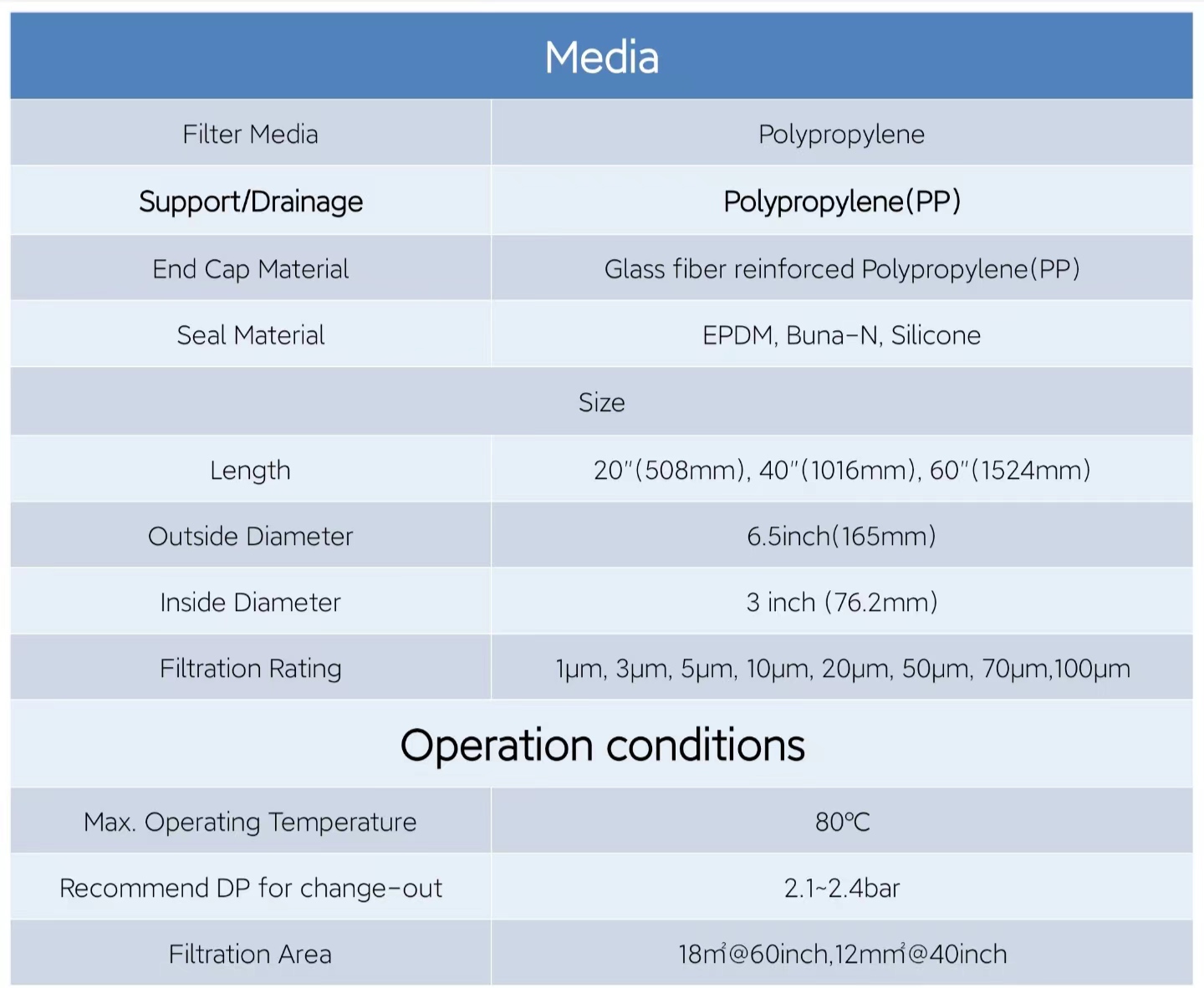

The 3M High Flow Series Filter Cartridges unfurl an impressive list of specifications that showcases their compatibility with high-demand industrial applications.

Primarily, these cartridges are engineered to handle considerable flow rates. They boast a commendable capability of enduring volumes up to 500 gallons per minute (gpm), significantly outmatching traditional filter cartridges. These high rates render the 3M High Flow Series a preferred choice for applications necessitating large quantities of high-purity fluid in a short duration.

Additionally, they showcase a sturdy thermal resistance, able to withstand operating temperatures up to 82°C. This high thermal limit fortifies their adaptability to a wide range of industrial processes involving elevated temperatures.

Essentially coreless, these cartridges bring forth a simplistic yet functional design. Owing to the lack of a traditional center core, they enhance ease of handling and installation while simultaneously minimizing waste generated during change-outs.

The cartridges also stand for exceptional filtration efficiency, a merit that is largely accredited to the use of a proprietary polypropylene filter medium. This material ensures superior particle retention, delivering a purified filtrate effectively.

Beyond that, the elevated surface area offered by their pleated filter media effectively prolongs the service life of the cartridges. This contributes to fewer cartridge replacements, reducing operational costs and downtime for maintenance or change-outs.

To sum up, the 3M High Flow Series Filter Cartridges, with their distinctive specifications, transform industrial filtration by catering to high flow requirements with efficient performance, durability, and longevity.

Difference

The 3M High Flow Series Filter Cartridges stand apart from traditional filter cartridges in several key aspects - signifying a leap forward in filtration technology and setting new standards for the industry.

1.High Flow Capacity: While conventional filter systems often struggle with limited flow capacities, the 3M High Flow Series shines with an impressive flow capability up to 500 gallons per minute. This drastically reduced filtration time contributes to enhanced productivity and efficiency in industrial processes.

2.Coreless Design: Traditional filters usually feature a core around which the filter media is wound or wrapped. In contrast, the 3M High Flow cartridges showcase a coreless design, simplifying the cartridge structure and consequently reducing waste generated during cartridge change-outs.

3.Advanced Filter Media: Where traditional filters might use rolled or wound media, 3M opts for a pleated filter media design. This approach significantly augments the filter surface area, thus prolonging cartridge lifespan and increasing contaminant holding capacity.

4.Proprietary Polypropylene Media: While conventional filters might utilize a range of materials for filtration, the 3M High Flow Series employs a proprietary blend of polypropylene. This ensures not just superior particle retention and high filtration efficiency, but also prevents fiber migration.

5.Thermal Resilience: Lastly, the High Flow Series boasts superior thermal resistance compared to conventional filters, with an operating temperature limit up to 82°C. This characteristic further broadens their applicability across various industrial scenarios with high-temperature requirements.

Cost performance

Enhanced Productivity: The standout advantage of the 3M High Flow Series is their ability to handle large volumes due to impressive flow rates of up to 500 gallons per minute. This capability directly contributes to enhancing productivity, making the High Flow Series an excellent investment for businesses aiming to increase output while maintaining high filtration efficiency.

Extended Lifespan: Owing to its unique pleated design, the 3M High Flow Series holds more contaminants, prolonging the cartridges' lifespan. Fewer replacements over a given duration render substantial financial savings, making it a worthwhile investment.

Reduced Maintenance Costs: The long-lived nature of the High Flow Series leads to lower maintenance requirements. When coupled with its easy-to-handle, coreless design, businesses can anticipate significant savings on labor costs related to cartridge change-outs.

Lower Operational Costs: The combination of high flow rates, superior filtration efficiency, extended lifespan and reduced maintenance results in significant operational cost savings over time.

Superior Quality: Despite offering savings in various dimensions, there's no compromise on the quality of filtration. The proprietary polypropylene blend used ensures excellent particle retention and prevents fiber migration, leading to quality end products.

Environmental Impact: The reduced frequency of cartridge replacements also generates less waste, making the High Flow Series an environmentally friendlier choice. This not only benefits the planet but possibly affects the company's bottom line through reduced disposal costs.

Environmentally

The 3M High Flow Series not only delivers performance but also manifests a commendable commitment to environmental sustainability, reaffirming 3M's adherence to responsible practices.

1.Reduced Waste Generation: The key environmental advantage of the 3M High Flow Series is its design, specifically enabling a longer lifespan compared to conventional filters. The superior capacity to retain more contaminants means fewer cartridge replacements, resulting in significantly less waste for disposal.

2.Lessens Carbon Footprint: The longer lifespan also means fewer manufacturing runs to produce replacement cartridges. This approach helps in lowering the overall carbon footprint as it reduces the energy consumption and emissions associated with the extraction, processing, and transportation of raw materials and finished products.

3.Energy Efficiency: The high flow efficiency of these cartridges means that they require less pressure to operate, equating to lower energy consumption. When applied across large industrial processes, the energy savings can be substantial.

4.Recyclable Components: The coreless design of the High Flow Series reduces the use of unnecessary material, and results in using recyclable plastic components wherever possible. The focus on recyclability aligns with the global shift toward circular economies and responsible waste management.

5.Reduced Chemical Use: The High Flow Series' excellent filtration efficiency minimises the need for additional process chemicals to treat the filtrate. This reduction plays a part in reducing the environmental footprint of industries, contributing to safer wastewater discharges and protecting aquatic ecosystems.

Product Features

The 3M High Flow Series brings an impressive roster of advantages to offer tremendous value to various industries:

High Flow Rates: True to its name, the 3M High Flow Series provides superior flow rates, enhancing productivity through an efficient filtration process.

Prolonged Lifespan: The unique pleated design of the High Flow Series increases its dirt holding capacity, which consequently extends its lifespan. This reduces the frequency of needed replacements and allows savings on labor and downtime costs.

Quality Filtration: Despite the high flow rates, the High Flow Series ensures high filtration efficiency. Its proprietary polypropylene blend guarantees excellent retention of particulates and prevents fiber migration, ensuring a high-quality filtrate.

Streamlined Maintenance: The lightweight and easily handled design simplify the cartridge change-out process, leading to substantially lowered maintenance effort and time.

Compatibility and Versatility: Its wide chemical compatibility makes the High Flow Series suitable for a broad range of applications across diverse industries.

Cost-Effective: Although it may entail a higher initial investment compared to conventional cartridges, the long-term cost savings in terms of fewer replacements, less maintenance, reduced downtime, and operational efficiency make the 3M High Flow Series a cost-effective choice.

Application

Renowned for its high-performance capabilities, the 3M High Flow Series finds broad application across a variety of industries, bringing significant benefits in each domain.

1.Food & Beverage Industry: The High Flow Series excels in providing outstanding filtration for food and beverage applications. Its superior flow rates and efficiencies ensure the safety and consistency of these products, meeting stringent quality controls while optimizing production rates.

2.Pharmaceutical Manufacturing: The High Flow Series assists in maintaining the highest level of sanitation and purity in pharmaceutical applications, crucial in producing safe and effective medicines. It helps remove particulates and contaminants from both water and active pharmaceutical ingredients (APIs).

3.Oil & Gas Industry: Mining industries make use of the High Flow Series for treating water used in extraction processes, ensuring the longevity of equipment by removing abrasive particles, which can lead to erosion damage.

4.Power Generation: Suitable for various stages of boiler feed water treatment or condensate polishing, it helps prolong the life of expensive equipment, ensuring efficient operation and lower maintenance.

5.Industrial Manufacturing: In processes where water is utilized for cooling or as a component of the end product, the High Flow Series proves invaluable. Its high flow rates support large-scale operations, maintaining the highest quality in the final product.

The results delivered by the High Flow Series are equally impressive. The unique design allows for exceptional dirt holding capacity and particle retention, ensuring excellent quality filtrate. Along with a substantial increase in productivity due to high flow rates, the extended cartridge life equates to fewer replacements, lower maintenance, and downtime. This yields significant cost savings and operational efficiency over the product's lifespan.

In summary, the application of 3M's High Flow Series brings about tangible improvements in filtration quality, productivity, and financial efficiency, making it a preferred choice in numerous industries.

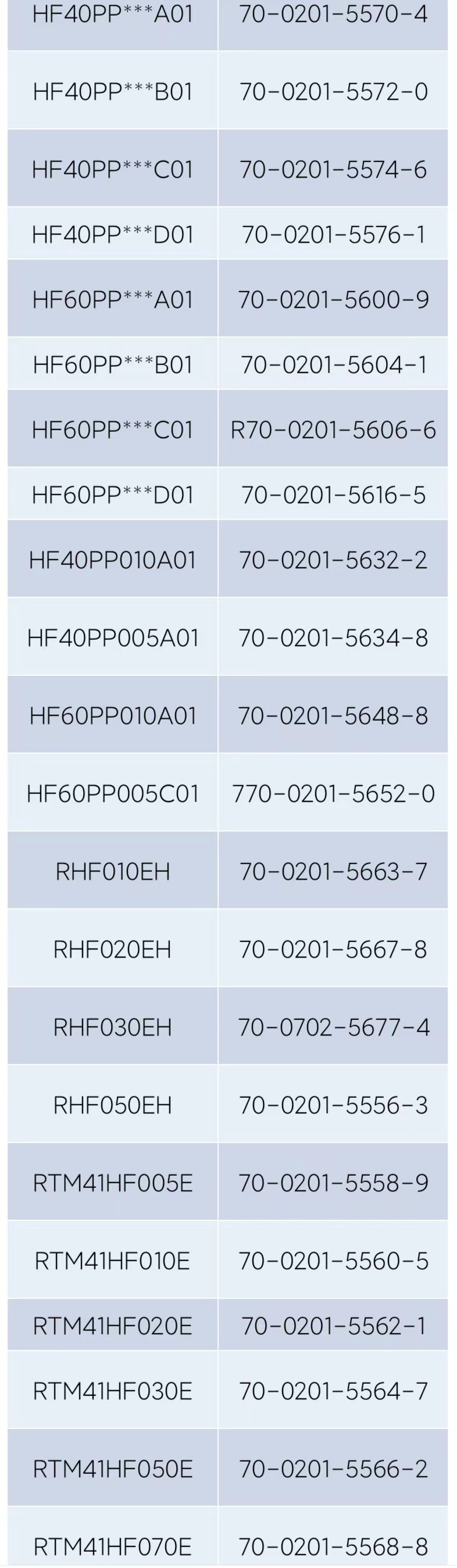

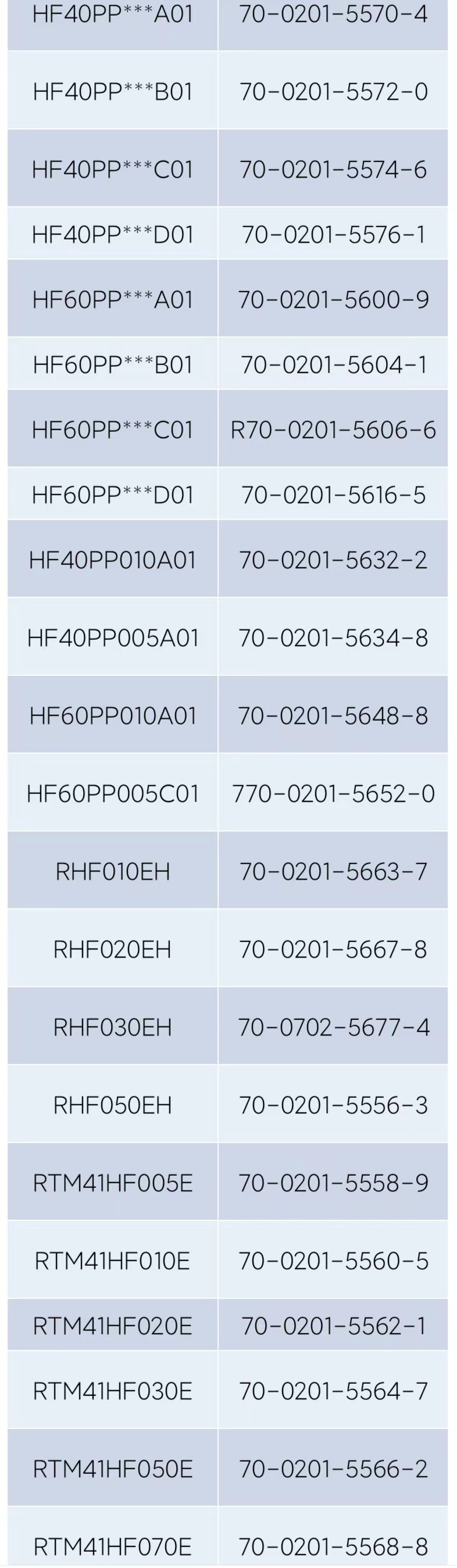

Replacement 3M Model

RELATED PRODUCTS

High-flow water filter cartridge