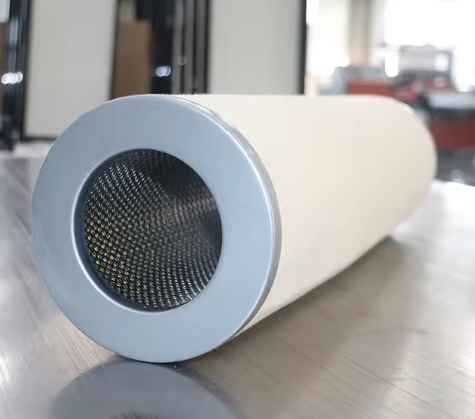

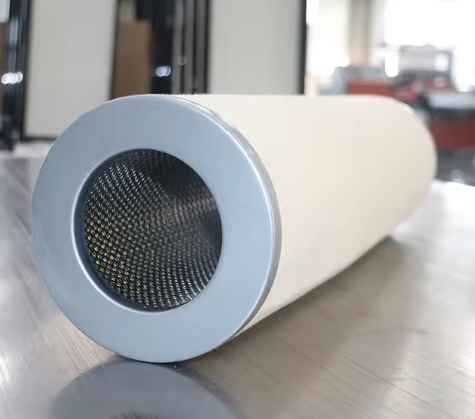

The CAA22-5 coalescing filter element is a professional industrial filter element designed for precise sewage treatment and oil-water separation. This filter element has efficient separation technology. Through its multi-layer composite structure filter material, it can accurately control the filtration accuracy, which can effectively remove higher concentrations of moisture, help protect the normal operation of subsequent equipment and ensure production safety. The uniqueness lies in its filter layer structure, which includes a filter layer, a demulsifying layer and a coalescing layer to optimize the filtration effect. The filter layer is mainly responsible for intercepting larger particle impurities, and the role of the demulsification layer is to increase the volume of water droplets, allowing them to condense into larger water droplets, making them easier to filter out. The coalescing layer is responsible for gathering the remaining water and small particles together to achieve final filtration and dehydration. Furthermore, due to the increase in the usage of filter material and filtering area, the CAA22-5 coalescing filter element has also greatly increased the dirt holding capacity and extended the service life. This makes it an extremely cost-effective option for long-term and heavy workloads. When we talk about application fields, CAA22-5 coalescing filter element has wide application in various industrial fields. It is often used in Pall coalescing dewatering oil filters and is most suitable in the field of oily sewage treatment. In addition, the characteristics of its coalescing filter material make it particularly important in the aviation field. It can filter impurities from aviation kerosene and has strong processing capabilities for coalescing moisture. Therefore, whether it is manufacturing, petrochemical, or aviation industry, CAA22-5 coalescing filter element has an important position and is widely used.

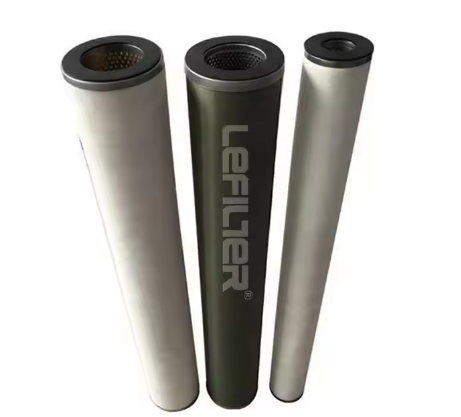

Detailed introduction of CAA22-5 coalescing filter element

The main product features of the CAA22-5 coalescing filter element are its super durability, high efficiency and excellent forward and backwash capabilities.

In terms of durability, the durability of the CAA22-5 coalescing filter element is mainly reflected in its impressive adsorption capacity and large dirt holding capacity. This comes from the complex multi-layer composite structure filter material it uses. This structure allows the filter element to not only absorb high levels of pollutants, but also maintain stable and efficient operation over a long period of time. This feature means users can replace filters less often, thereby significantly reducing operating costs while ensuring long-term performance of the equipment.

In terms of efficiency, the high efficiency of the CAA22-5 coalescing filter element is also one of its outstanding features. This is because it adopts a scientific and reasonable distribution of filter fiber layers, which allows it to efficiently coalesce and achieve extremely high filtration accuracy in the process of processing liquids and gases. It can also effectively reduce moisture, making the treatment medium drier, preventing the occurrence of hardening, corrosion and scaling, and effectively ensuring the stable operation of the equipment and production safety.

When it comes to the evaluation of forward and backwash capabilities, the CAA22-5 coalescing filter element also performs well. Due to its cleverly designed filter element structure and materials, it can effectively withstand more frequent forward and backwash operations. This provides users with greater operational flexibility and can perform cleaning according to actual needs to reduce machine downtime, thus improving overall production efficiency.

Technical specifications: Introduce detailed specifications such as product size, filtration accuracy, etc.

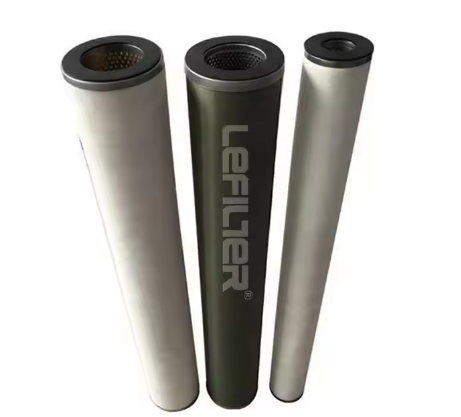

First of all, in terms of size, the CAA22-5 coalescing filter element has complete specifications and can be flexibly adapted to various filtration needs. It can be installed and used smoothly in a variety of equipment, and can achieve excellent performance whether in large industrial facilities or in some delicate equipment.

Secondly, in terms of filtration accuracy, the CAA22-5 coalescing filter element is also eye-catching. The filtration precision of this filter element can reach 0.1 micron, which is higher than that of many traditional filter elements. It can remove extremely small particles and microorganisms, ensuring the cleanliness and purity of the outlet fluid.

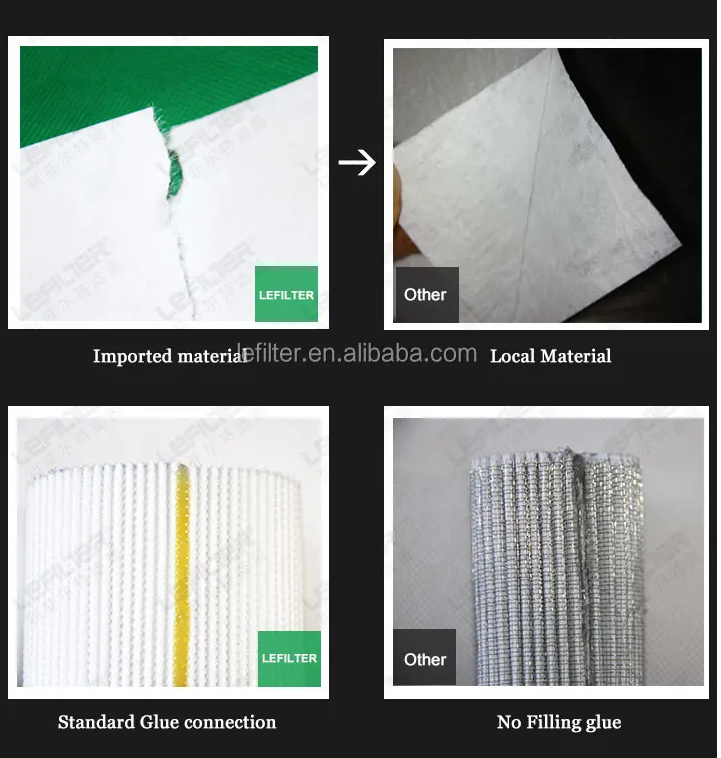

In addition, the CAA22-5 coalescing filter element also uses surface-treated glass fiber or polyester fiber as the coalescing medium, so that the filter medium has good coalescing performance. The selection and design of this kind of filter material enables the filter element to achieve high separation efficiency during filtration, while also providing stable operation guarantee for subsequent processes.

In addition, the CAA22-5 coalescing filter element uses a 200-mesh stainless steel oil-water separation mesh, which makes the filter element have less flow resistance during the filtration process and also improves the separation efficiency.

Globally, we can already see many successful application cases. For example, in traditional industrial fields such as metallurgy, petroleum, chemical industry, and electric power, CAA22-5 coalescing filter elements are widely used. Since the environment in these industries is often complex and the requirements for cleanliness and purity are relatively high, a filter element that can effectively remove impurities and can operate for a long time is needed to ensure the stability of the production process. The CAA22-5 coalescing filter element was born based on such needs. Not only can it efficiently filter out tiny particles, but its special design can also coalesce and separate water to ensure the cleanliness of the fluid. In addition, its powerful filtration capacity and durability also enable it to work stably and stably in complex and harsh environments, and can stand the test of time and practice.

In Russia, CAA22-5 coalescing filter elements are also widely used. Due to Russia's vast geographical scope and diverse climatic environment, industrial production often faces the problem of excessive impurities and moisture in liquids and gases. In this environment, a powerful and reliable filter element is needed to handle these complex problems, and the CAA22-5 coalescing filter element meets such needs. Whether in the oil fields in the cold Siberian region or in the highly industrialized Moscow and St. Petersburg, the CAA22-5 coalescing filter element plays an important role. Its powerful filtration capacity and durability enable it to operate stably in Russia's harsh environment and is highly praised by users.

Why is the CAA22-5 coalescing filter element particularly suitable for Russia’s industrial environment? This is mainly due to its special design and manufacturing process. First of all, its size and shape design allows it to match various oil filters and filtration systems to adapt to different industrial environments and needs. Secondly, its filtration accuracy is high, it can not only filter out tiny particles, but also effectively coalesce and separate moisture, meeting the changing and complex needs of the Russian industrial environment. Finally, its durability and stability also enable it to operate continuously in complex and harsh environments, ensuring the stability of the production process.

In general, the CAA22-5 coalescing filter element has demonstrated excellent performance and wide adaptability, both globally and in Russia's special industrial environment, providing a strong guarantee for the stable operation of global industrial production. In the future, we also expect it to play a greater role in more fields and regions.

What are the advantages of CAA22-5 coalescing filter element compared with other products on the market?

The CAA22-5 coalescing filter element is a high-quality product manufactured by Pall Corporation. It has won widespread praise from customers worldwide due to its excellent performance and remarkable applicability. Among the filter elements on the market, the CAA22-5 coalescing filter element stands out due to its many advantages. Herein, I will elucidate its unique advantages.

First and foremost, the CAA22-5 coalescing filter boasts superior water separation capabilities. As a highly efficient water-removing filter, the CAA22-5, with its unique design and material selection, can effectively separate high concentrations of water from the media, ensuring normal operation of the equipment. This feature is particularly essential for many industrial applications operating under harsh conditions, making this filter an indispensable component across sectors - whether it's aviation, petroleum, or chemical industry.

Subsequently, the CAA22-5 coalescing filter demonstrates exceptional filtering performance. It primarily utilizes specially processed glass fiber or polyester fiber as the coalescing medium. The selection and design of these materials endow the CAA22-5 with excellent coalescing performance. In terms of filtering impurities and water, its filtering accuracy can reach 0.1 microns, ensuring fluids in the system are free from impurities and water, thus ensuring stable operation of the equipment.

Moreover, the application scope of the CAA22-5 coalescing filter is extraordinarily wide-ranging. Particularly in Pall's coalesce deracinating oil filter, the CAA22-5 coalescing filter can demonstrate its dual function, that is, filtering out impurities from aviation kerosene and coalescing water at the same time. This allows the oil filter to maximize its performance, making the operation process more efficient and safe.

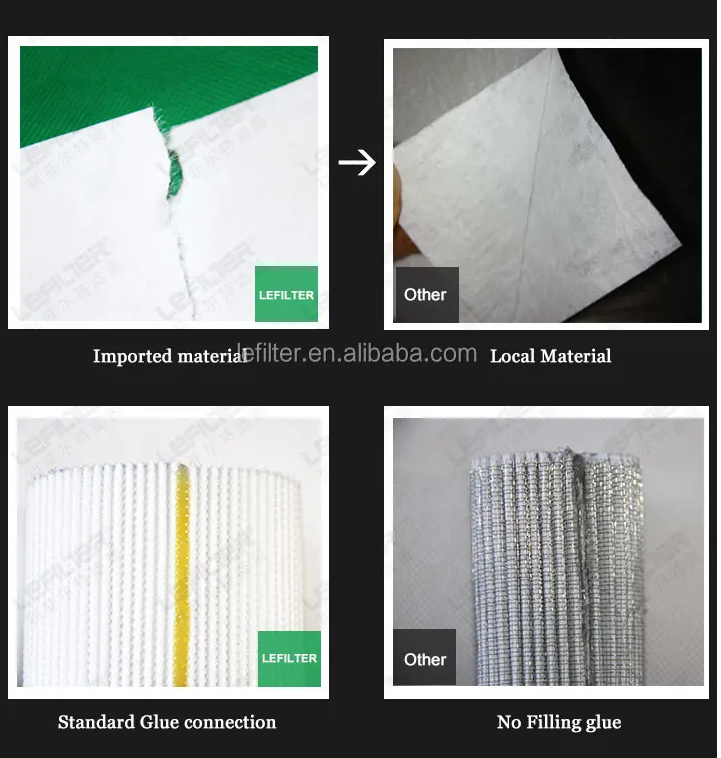

Finally, the CAA22-5 coalescing filter chooses filtering materials discerningly. The filter uses imported glass fiber medium, which greatly enhances the filtering efficiency of the filter, making it capable of achieving over 99.9% filtering effect, thus leading the way among such products.

In conclusion, the CAA22-5 coalescing filter, with its unique design, superior material selection, and wide applicability, holds a unique place among all the filter products on the market. Whether it's its efficient water separation capability or precise filtering performance, all of these make it a high-quality filter product on the market, earning it a prominent place amid fierce market competition.

The detailed steps for replacing the CAA22-5 coalescing filter element are as follows:

Step 1: Safety Preparations First, make sure to completely cut off power to the device to avoid any accidental injury. Specifically, connected circuits and power switches should be turned off. Next, prepare appropriate protective equipment such as gloves, safety glasses, and work clothes. This is because during the process of replacing the filter element, you may come into contact with the old filter element containing impurities and oil. At the same time, it is very important to keep the work area clean so that there is no accidental contamination during filter replacement.

Step 2: Open the filter housing. According to the specifications of the equipment, use the corresponding tools to open the filter housing. This process requires extreme caution, and no force should be used to avoid damaging the reusable filter housing part. Once all the fixing elements are loosened, you can gently remove the upper part of the filter housing.

Step 3: Take out the old filter element. Next, take out the old CAA22-5 coalescing filter element one by one. When removing, be careful not to scratch the outer shell of the filter element and prevent messy debris from entering the system. Then, use professional tools to clean the filter element position to ensure that the next new filter element will not be affected by past residues.

Step 4: Install the new filter element. Before starting to install the new filter element, conduct a comprehensive inspection of the filter element. Make sure it is complete and free of any stains. When installing the new filter element in place, be sure to ensure that the filter element is evenly and symmetrically positioned to prevent air leakage and unreasonable failure of the early filter element.

Step 5: Determine the installation position of the filter element. After installing the new filter element, confirm again whether the filter element and filter housing are properly installed to ensure that no air remains inside the filter element. After completing the above steps, seal the filter housing again.

Step 6: Check the installation work. After completing the assembly process, repeatedly check whether the filter housing is completely sealed to prevent any risk of leakage.

Step 7: Test the new filter element. Use a hand pump to take a snapshot of the filter element to confirm that there are no signs of serious leaks or equipment failure.

Step 8: Start the equipment. Before starting the equipment, a period of trial operation is required to confirm that the equipment can operate normally and that the new filter element is installed correctly.

Note that this process may involve special steps, depending on the specifics of your device and work environment. When performing these steps, be sure to refer to the device manufacturer's specific guidelines. This process serves as a general guide for replacing the CAA22-5 coalescing filter element, but if you encounter any problems during the replacement process, it is strongly recommended that you seek professional help.

Step 1: Visually check the equipment for leaks. After replacing the new filter element and before restarting the equipment, you need to carefully check the leakage points on the surface of the filter element and the equipment. This also includes checking the fixed part of the filter element to confirm that the filter element is securely installed in the correct position and that the filter element housing is completely closed. Make sure all interface parts are tightened and there are no leaks. Once a leak is discovered, stop work immediately and seek professional help.

Step 2: Work inspection Before restarting the equipment, you need to confirm again that the filter element has been correctly installed into the equipment and the filter element shell has been correctly packaged. In particular, check whether the filter element is evenly installed in the seat, whether the housing is sufficiently closed and whether all connecting parts have been properly handled. Also, make sure that all mounting components are properly secured in place.

Step 3: Start the device step by step and conduct preliminary monitoring. After the above two steps, you can carefully start your device for the initial test. Within a few minutes of first turning on the device, listen for any unusual sounds or touch it for excessive vibrations. Such signs may indicate some internal problems. If you hear unusual sounds or feel unusual vibrations, turn off the device immediately and look for the cause.

Step 4: Strictly test the equipment performance indicators. After starting the equipment, the first performance indicator to pay attention to is the pressure of the equipment. Check the indication on the equipment pressure gauge to confirm whether the pressure is within a reasonable range. If the pressure is too high, it may indicate that it is partially clogged; if the pressure is too low, it may indicate that the filter element is not installed correctly. Another thing to pay attention to is the flow rate of the equipment. Make sure the flow rate of the equipment is normal. If the flow rate is too slow, it may indicate a clogged filter element. At this time, you need to shut down the equipment and check the filter element.

Step 5: Short-term and long-term close observation After the equipment officially starts operation, you need to observe its short-term and long-term performance to confirm that the performance of the equipment has not been affected. For example, changes in output quality, sound and vibration of equipment operation, heat dissipation and power consumption of equipment, etc. Record this data and analyze it to confirm whether the equipment's performance indicators are as expected.

At the same time, special attention needs to be paid to any possible signs of new malfunctions. If any emergencies occur, you need to stop the equipment immediately and seek expert help. If the equipment works normally for a period of time, you can be sure that the filter element has been replaced correctly.

This series of processes may take some time, but please be patient. Because this ensures that any possible problems can be detected and dealt with in time, ensuring the normal operation of the equipment and the continuation of production.