What is a dust filter cartridge?

What is the history of air filter?

The origin of air filter cartridges can be traced back to the Industrial Revolution, when people's understanding of air quality began to gradually increase, and the prototype of air filter cartridges came into being at this time. However, the real development of air filter cartridges dates back to the early 20th century. With the advancement of science and technology, the principles and manufacturing methods of air filter cartridges have been significantly improved.

Over the past century or so, air filter cartridges have evolved from simple cotton filters to the complex structures they are today, from a single filtration function to now filtering a wide range of gases, including viruses and particulates. In this process, many researchers and engineers have worked hard. From market demand, scientific discovery, to technological innovation, all of these have inspired changes in air filter cartridges.

Today, air filters have become an indispensable part of our lives. They play a decisive role in many key areas, such as household and industrial air purification, vehicle and aircraft engine performance, medical and scientific research safety, etc. What is worth looking forward to is that in the days to come, with the further development of technology, air filter cartridges will play a greater role in areas such as air quality improvement and public health protection. This is just part of the never-ending scientific journey, let us look forward to the next leap in air filter cartridges.

What is a dust filter cartridge?

The air dust filter cartridge is a piece of equipment whose main function is to filter and remove dust and other impurities in the air. This device usually consists of a filter material that effectively captures and blocks particulate matter in the air flow.

What is air filter used for?

1. Pharmaceutical industry: In this industry, equipment such as tablet presses, mixers and granulators generate large amounts of dust during the production process. Dust cartridges are devices used to capture and filter these tiny particles. In the pharmaceutical industry, the service life of dust filter cartridges is usually 6-12 months, depending on the use environment and work intensity.

2. Metallurgical industry: Equipment such as electric furnaces and blast furnaces produce large amounts of dust and particulate matter. These devices typically use high-temperature, durable dust collection cartridges. Due to the harsh working environment, the service life of the dust filter cartridge is generally 3-6 months.

3. Wood processing industry: such as sawdust machines, shaving machines and other equipment. The wood dust produced by these devices can be captured by efficient dust collection cartridges. Typically, the frequency of dust filter cartridge replacement depends on the frequency and intensity of wood processing and can be as short as a few weeks or as long as a few months.

4. Stone industry: Stone cutting machines, grinders and other equipment will produce a large amount of stone particle dust during the processing process, which requires the use of tank-type dust removal equipment equipped with dust removal cartridges to deal with it. Because stone dust causes greater wear and tear on the dust removal filter cartridge, its service life is relatively short, usually 3-4 months.

In addition, there are many other industries such as mining, chemical industry, electric power, etc. that also use dust filter cartridges. How long a filter cartridge lasts and how often it needs to be replaced also depends on factors such as how long your equipment has been operating, the types of materials the equipment handles, and the material and design of the filter cartridge. I recommend that you inspect it regularly and replace it according to the manufacturer's recommendations to ensure optimal performance of your device.

What are filter cartridges made of?

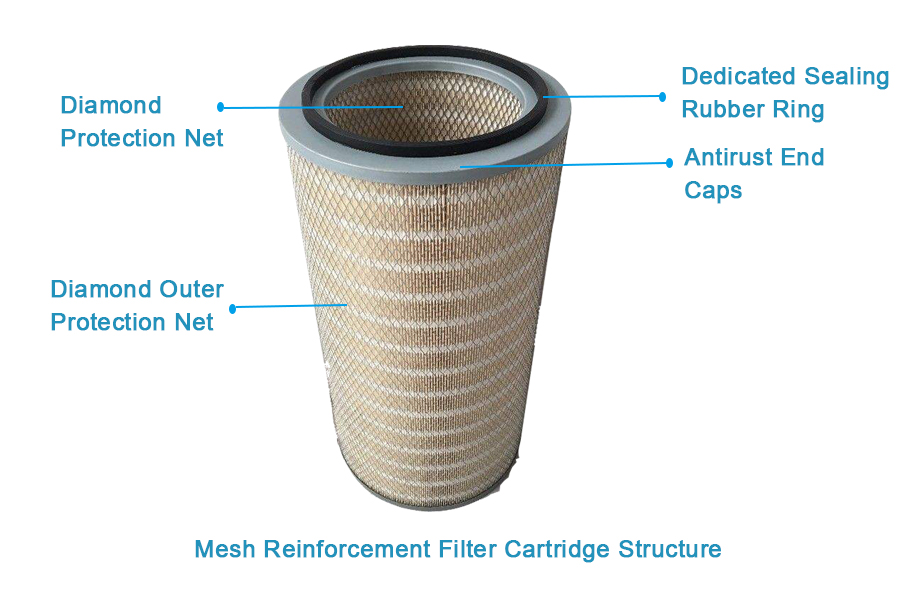

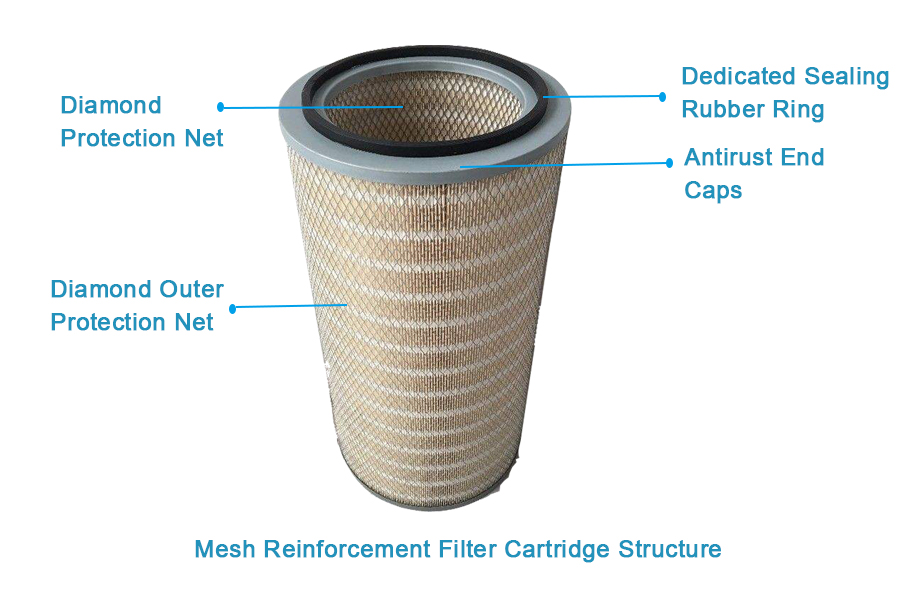

The air dust filter cartridge is an important air filtration equipment, which mainly consists of the following parts:

1.Filter material: The filter material is located inside the filter cartridge and is the core part of the dust filter cartridge. Its main task is to filter and remove dust particles in the air. The type and selection of filter media determines the filtration efficiency and performance of the filter cartridge. Common filter materials include non-woven fabrics, glass fiber, activated carbon, ceramics and ferrite materials.

2.Support net or frame: The support net or frame is usually made of metal material to support the filter material and prevent it from deforming or breaking after absorbing dust and particles. It also helps maintain the stability of the filter cartridge and ensures its performance under working conditions.

3.End caps: The end caps are usually located at both ends of the filter cartridge and are used to secure and seal the filter cartridge to prevent unfiltered air and dust from bypassing the filter material.

4.Sealing ring: The sealing ring is located at the installation interface of the filter cartridge. It is used to ensure the tightness between the filter cartridge and the equipment and avoid air leakage.

These components work together to effectively capture and adsorb dust and particles in the air, thereby achieving the purpose of dust removal. Selecting and configuring the appropriate dust filter cartridge is extremely important to improve air quality and protect machinery and equipment.

How are air filters classified?

Air filter cartridges can be classified from many angles. Here are some common classification methods:

1. For particles of micron or sub-micron size, the more particles can be filtered out, the higher the efficiency of the filter cartridge.

Classification by filtration efficiency: Air filter cartridges can be divided into primary-efficiency, medium-efficiency and high-efficiency filter cartridges

Primary filter cartridge: It can mainly filter out particulate matter ≥5-10 microns, and its filtration efficiency is generally around 30% - 60%. Usually used for pre-filtration, such as pre-filtration in air-conditioning systems, primary filtration in ventilation air purification, etc.

Medium-efficiency filter cartridge: It can mainly filter out particulate matter ≥1 micron, and the filtration efficiency is generally 60% - 95%. For example, laminar flow operating rooms and air purification in the food and beverage industry.

High-efficiency filter cartridge: It can filter out particles above 0.3 microns, with a filtration efficiency of 99.97% - 99.9999%. High-efficiency filter cartridges are mainly used in places that require very high air cleanliness, such as pharmaceutical engineering, biological laboratories, thermal nuclear power, semiconductor manufacturing, etc.

2. The selection of filter material for the filter cartridge is the key, which determines its filtration efficiency and service life. Classification by material:

Nonwoven fabric: This is the most common filter cartridge material, and it can be said that almost all air filter cartridges will be used. Nonwoven fabrics have good filtration effects and are low cost, making them very suitable for mass production.

Nanofiber: Nanofiber material has a small fiber diameter and a large specific surface area, and has a higher ability to capture tiny particles in the air.

Glass fiber: Many high-efficiency filter media use this material because it has a high filtration effect and can maintain stable performance for a long time.

Activated carbon: Activated carbon has extremely high adsorption capacity. For some harmful gases and industrial waste gases, filter cartridges made of activated carbon can achieve very good filtration effects.

Metal: For some special filtration requirements or industrial environmental conditions, metal filter cartridges can be selected, such as stainless steel, aluminum, copper and other metal filter materials.

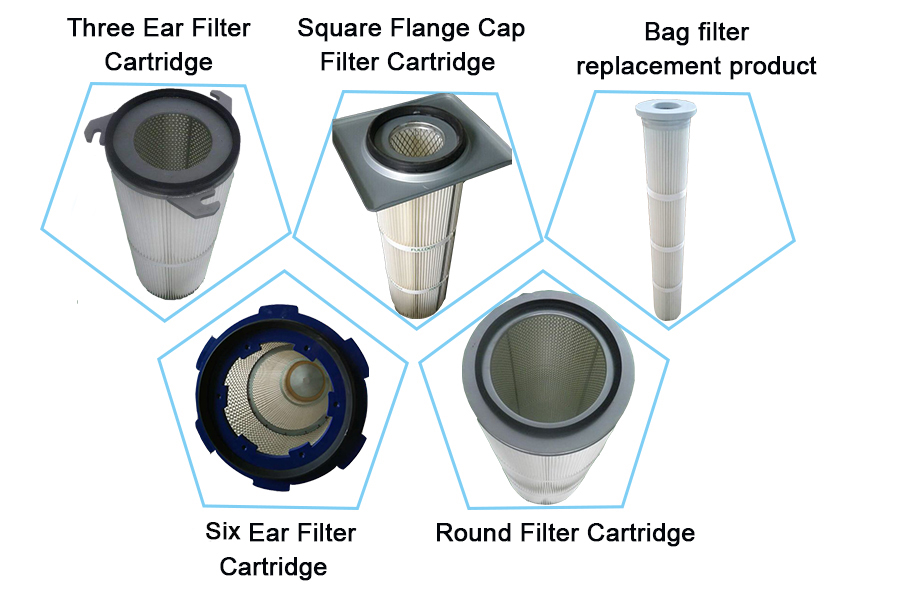

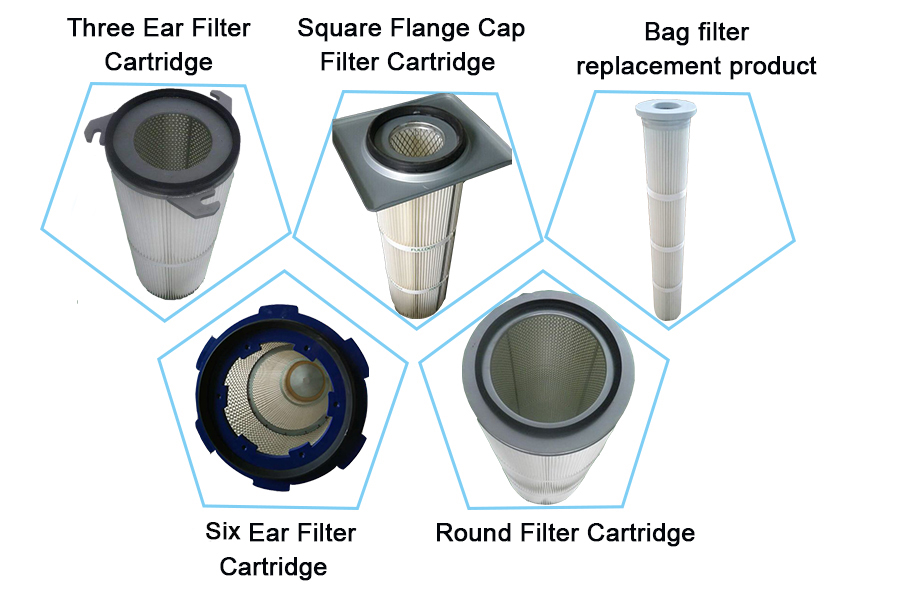

3. Filter cartridges of different shapes can play a greater role in specific application scenarios, classified by shape:

Cylindrical filter cartridge: This type of filter cartridge is shaped like a regular cylinder, and its interior is filled with filter material that captures flying particles and other impurities. Due to their shape, cylindrical filter cartridges provide a large area of filtration, which helps increase the efficiency and durability of the filter cartridge. Additionally, its shape also facilitates efficient filtration while maintaining good airflow.

Conical air filter: The top of the conical air filter is smaller than the bottom and is tapered in shape. Like other filter cartridge shapes, conical filter cartridges are designed to maximize the filtration surface, thereby improving air flow and filtration efficiency.

Conical air filter: The top of the conical air filter is smaller than the bottom and is tapered in shape. Like other filter cartridge shapes, conical filter cartridges are designed to maximize the filtration surface, thereby improving air flow and filtration efficiency.

Triangular air filter cartridge: The triangular air filter cartridge has a unique triangular shape. This design allows it to provide a larger filtration surface area in a limited space. At the same time, the triangular shape also helps improve air flow and filtration efficiency.

4. Air filter cartridges can also be divided into:

Industrial air filter cartridges: These cartridges are primarily used on production lines to prevent machine parts from being damaged by dust and other particulate matter. For example, they may be used in industrial applications such as chemical processes, food processing, wood treatment, etc.

Car air filter cartridge: In the car, the air filter cartridge is mainly used to filter the air entering the engine and remove pollutants that may be harmful to the engine to protect the engine and ensure its efficient operation.

Household air filter cartridges: usually used in household equipment such as air purifiers, air conditioners and fans to improve air quality and provide families with a healthier and safer living environment.

Medical air filters: In medical environments, such as operating rooms, wards, laboratories, etc., air filters are used to maintain air cleanliness and reduce the spread of germs and microorganisms.

HVAC air filter cartridges: In heating, ventilation, and air conditioning (HVAC) systems, air filter cartridges help provide a clean, healthy environment by removing dust and particles within the system that can cause contamination of components.

5. Classification by replacement cycle: Some filter cartridges need to be replaced more frequently, such as disposable filter cartridges, while some can be used for a longer period of time due to the materials or technology used, such as long-life filter cartridges.

What are the characteristics of air filter?

High-efficiency filtration: Our dust filter cartridges are manufactured using advanced filter materials and equipment, which can effectively filter out most particles and dust, ensure the cleanliness of the outlet airflow, and help improve the working environment and protect equipment.

Large area: Due to the shape design of the filter cartridge, it can provide a large filtration area, allowing it to maintain good filtration effects under high flow rates.

Easy to replace: We have designed the filter cartridge to be easy to replace. Simple operation can complete the replacement of the filter cartridge, avoiding complicated maintenance steps.

Durable: Our filter cartridges use corrosion-resistant materials so that they can maintain good performance in various environments and are durable for long-term use.

High cost performance: We provide cost-effective prices, and the maintenance cost of the filter cartridge is low, and the cost advantage is obvious after long-term use.

Air filter cartridge production process:

Our air filter cartridge production and quality control processes follow strict operating standards and inspection procedures:

Material selection: First select high-quality filter materials, which generally include non-woven fabrics or glass fiber and other materials.

Cutting filter material: Precisely cut using professional machines according to the designed size and shape.

Folding and fixing filter material: Use tools to fold the cut filter material into a predetermined shape. The folded filter material is then fixed in a sturdy frame or casing.

Install end caps: Install metal or plastic end caps on the upper and lower ends of the air filter cartridge.

Tight sealing: Hot melt glue or other adhesives are generally used to completely seal the filter media and frame to prevent leakage.

Complete assembly: For some products with multi-layer filtration or pre-filters, additional assembly steps are required.

Strict random inspections will be carried out at every step, focusing on the following elements:

Filter material quality: Check the filter material for cracks, breakage or other damage.

Folding uniformity: The position and depth of the folds need to meet the design requirements to ensure normal passage of air.

Installation strength: Check the end cover and filter material, and whether the connection between the filter material and the shell is firm to avoid damage or falling off during operation.

Dimensional accuracy: The geometric dimensions of each product need to meet the design requirements to ensure smooth installation.

Edge sealing effect: Check whether the filter cartridge is leaking at the end of its service life.

Finally, we will conduct air filtration performance testing and appearance inspection to ensure that the performance of each filter cartridge meets the standards before it is judged as a qualified product and is ready to be shipped out of the factory.

How to choose an air filter cartridge:

I would like to provide you with some practical guidance on selecting an air filter cartridge:

Understand your needs: Before choosing an air filter cartridge, you need to understand your specific needs. For example, what types of particles do you want to filter out? What model is your device? This is very important in choosing the right air filter cartridge.

Check the filter material: Different air filter cartridges may have different filter materials. Generally speaking, non-woven fabrics and fiberglass are commonly used filter materials, and you need to choose the appropriate filter material based on your specific needs.

Determine the size: Make sure the filter cartridge you buy is the right size for your equipment. If it is not the right size, the filter may not fit into your unit or may not filter the air effectively.

Check efficiency: The efficiency rating of a filter cartridge indicates the particle size it can filter. Generally speaking, the higher the efficiency, the smaller the dust particles that can be filtered. However, the higher the efficiency of the filter cartridge, the greater the resistance.

Choose a brand: Choose air filter cartridges from well-known brands because their product quality is more reliable and their after-service services are better.

Price: In addition to considering the above factors, price is also an important consideration. The right air filter cartridge should have the ideal balance of performance and price.

The above are some basic guidelines for choosing an air filter cartridge. I hope it can help you. If you have any other questions, please feel free to consult me at any time!

How to replace the air filter cartridge:

We are pleased to provide you with simple steps for replacing your air filter cartridge. Keep in mind that there may be slight differences between devices, but the replacement process is basically the same.

Unplug: First, turn off and disconnect power to your air purifier. This is for security reasons.

Disassemble the existing filter cartridge: Open the filter cartridge cover or filter cartridge storage chamber and take out the existing air filter cartridge. This may require undoing some screws, snaps or applying some force.

Cleaning the Equipment: Before reinstalling a new filter cartridge, clean the filter cartridge storage area with a clean, damp cloth.

Install the new air filter cartridge: Then, install the new air filter cartridge. Make sure the filter cartridge is oriented correctly and insert it into the correct position.

Reinstall to make sure it is secure: Reinstall the filter cartridge cover or storage chamber, making sure all screws or buckles are in place.

Restore power and check: Restore power to the device and wait for a while after turning it on to make sure the device is working properly.

The above is the process of how to replace a new air filter cartridge. Remember, replacement is generally recommended every three to six months, and it’s best to do this regularly based on device usage and manufacturer recommendations. If you have any other questions, please feel free to consult me at any time.

Commonly used air filter cartridge models number:

| 8PP-42057-00 | P033063 | P191281 | 7244420 | P156334 | 8PP-23099-00 | P191675 |

| P190817 | P191521 | P525984 | EZ-4490100 | P191549 | P032953 | P191843 |

| P190906 | P191649 | 8PP-40766-00 | P191564 | P191844 | P155248 | 8PP-47402-00 |

| P191204 | 8PP-22269-00 | P032949 | P191695 | P524836 | 8PP-21028-00 | P191137 |

| 3EA-24742-00 | P032948 | P191222 | P199472 | P191874 | P143515 | PP-45368-00 |

| 8PP-24627-00 | P151244 | P527080 | 8PP-25370-00 | P191877 | P607376 | P190999 |

| P190598 | P191214 | P511356 | P031575 | 8PP-32582-00 | 8PP-46638-00 | P030036 |

| 3EA-24740-00 | 8PP-21347-00 | P527078 | P613439 | P031410 | P031685 | P032355 |

| P190620 | P145891 | P030915 | 8PP-48001-00 | P190896 | 8PP-72483-01 | P191889 |

| P191812 | P191233 | P030917 | P191194 | P032801 | P134507 | P030627 |

| P191211 | P030904 | 8PP-32537-00 | 8PP-44103-00 | P191856 | P191562 | P191920 |

| P190818 | P030906 | P190911 | 8PP-47400-00 | P191861 | 8PP-72482-01 | P199413 |

| 8PP-4058-00 | P030907 | 8PP-48105-00 | P030926 | 8PP-2600-427-226 | P032952 | P199476 |

| P031626 | P031336 | 8PP-72476-01 | P190884 | 8PP-28888-00 | P191536 | P199612 |

| P199407 | P191865 | EZ-7244201 | P191133 | 8PP-48107-00 | P191563 |

|

| 8PP-72460-01 | P03-0025 | P191550 | 8PP-20247-00 | 8PP-72477-01 | P191654 |

|

| P033063 | P191037 | P031388 | 8PP-20306-00 | P032951 | P125744 |

|

| P191521 | P191280 | 8PP-20639-01 | 8PP-25116-00 | P191244 | P147320 |

|

| P191649 | P030151 | P033096 | 8PP-72478-01 | P191551 | P031789 |

|

| 8PP-22269-00 | P191039 | P191825 | P149554 | P191866 | P191900 |

|