Introduction and application of large flow filter elements

Foreword

In the past few decades, the development and progress of high-flow water filter elements has revealed mankind's profound understanding of environmental protection and sustainable development.

Historically, water sources full of mixed impurities have always brought many challenges to industrial production and human life. As far back as ancient Rome, we've been trying to purify drinking water through crude filters made of bitumen and sand. However, its cleanliness and flow rates were not up to today's standards.

In the 19th century, the unfolding of the large-scale industrial revolution brought an urgent need for efficient and clean water sources, which gradually gave rise to early high-flow filter technology. The effect of the first-generation product was not ideal, and problems such as fatigue fractures occurred frequently. However, these difficulties did not stop our determination to develop more advanced filter elements.

The rapid advancement of science and technology in the 20th century has enabled the rapid development of innovation in high-flow filter elements. In particular, advances in material science have significantly improved the load capacity, cleaning effect and service life of large-flow filter elements. In addition, the unique design of the high-flow filter element also enables it to cope with various industrial production and domestic water needs.

In the 21st century, with the strengthening of environmental awareness and the continuous development of science and technology, large-flow water filter elements have been further optimized to meet various more stringent filtration needs. Not only that, the application of high-flow filter elements has gradually expanded to agricultural irrigation, seawater desalination, wastewater treatment and other fields.

To sum up, the development of high-flow water filter elements is the result of the interaction of human wisdom, technological progress and environmental protection needs. We look forward to the future, where this pace of progress will never stop, bringing more possibilities to our environment and life.

What is a high flow filter?

The high-flow filter element is an important environmental protection equipment in our daily life and can be said to be the protector of our health. So, what exactly is it, what is it used for, and how does it work? Let’s explore the familiar and unfamiliar high-flow filter elements together.

First of all, the basic meaning of high-flow filter element lies in the two parts of "large flow" and "filter element". As the name suggests, "large flow" refers to its ability to handle a large amount of water in a short period of time, and "filter" refers to the key component used to clean this water. Simply put, a high-flow filter element is a water filter with high efficiency and large processing capacity.

So, how does it work? Its working principle is very similar to the sieve we use when cooking. The water source flows into the filter element. The microporous structure of the high-flow filter element only allows water molecules to pass through, while larger impurities will be blocked out. After the filter element is cleaned, the water becomes pure and usable.

Finally, let’s take a look at the application range of high-flow filter elements. Large-scale industrial production and public facility water supply all require the use of high-flow filters, and they can even be seen in our household water systems. The water source cleaned by the high-flow filter element can be used for drinking, cooking, bathing, laundry, and even irrigating farmland. It can be said that without the cleaning treatment of high-flow filter elements, our life will become unimaginable.

Through the above introduction, I believe you have a preliminary understanding of high-flow filter elements. Of course, there is much more to explore in this vast subject, so let’s move forward and dive into the wonderful world of high-flow filters.

The large flow filter element consists of the following parts:

The high-flow filter element is a complex filtration product, and each component plays a vital role in product performance. The following four main parts form the core of the high-flow filter element:

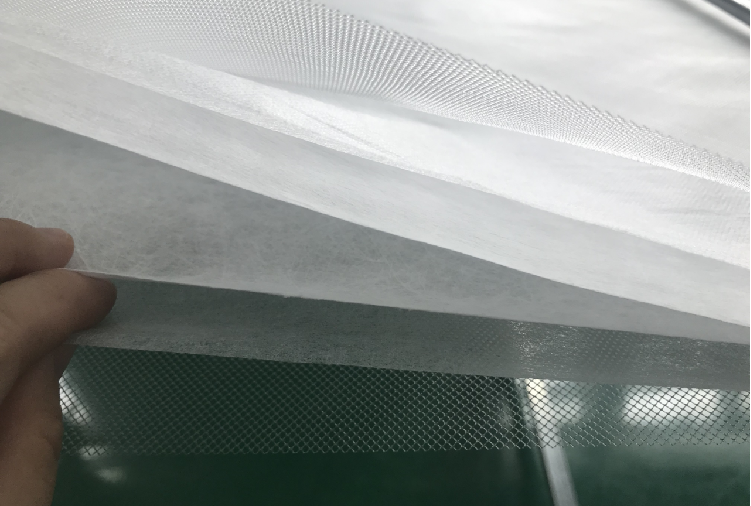

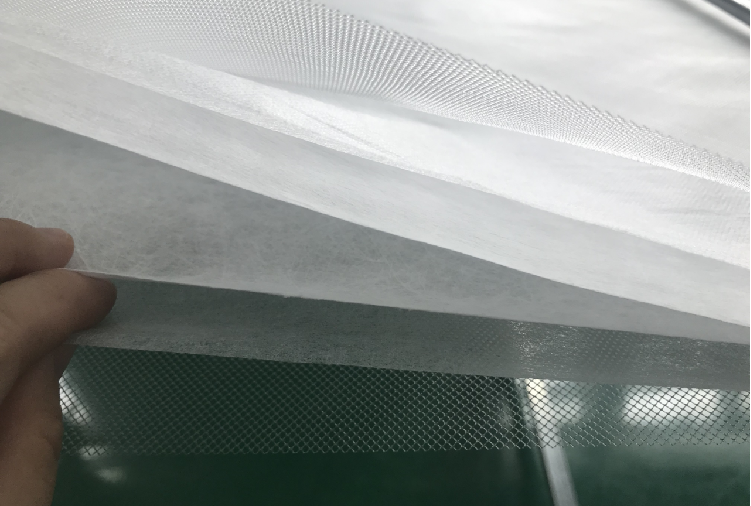

Filter material: The filter material is the core of the filter element. Common ones include pp film, glass fiber, etc. The selection and design of filter material directly determines the filtration efficiency, filtration accuracy and service life of the high-flow filter element. During the water filtration process, the microporous structure of the filter material can effectively intercept and absorb impurities and harmful substances from the water, ensuring that the water is clean.

Support structure: The support structure includes inner and outer frames and central tubes, etc. It mainly plays the role of protecting the filter material, maintaining the shape of the filter element and providing sufficient mechanical strength. The sophisticated design of this part can ensure that the filter element works stably under high flow conditions and prevent fatigue fracture of the filter element.

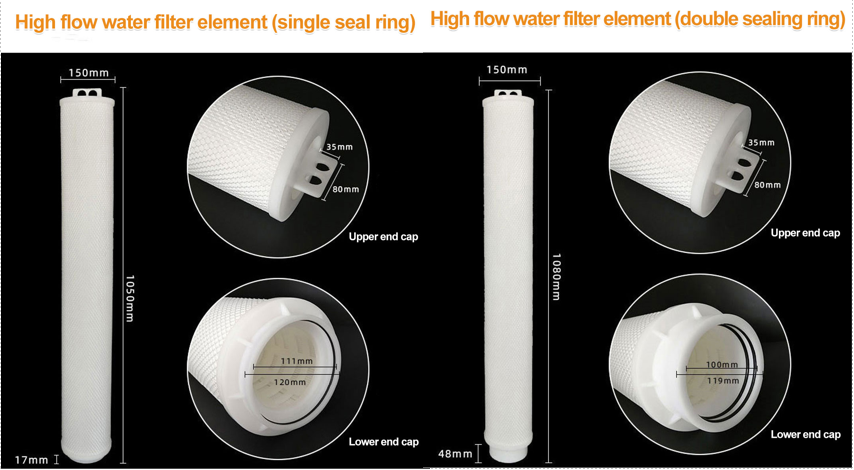

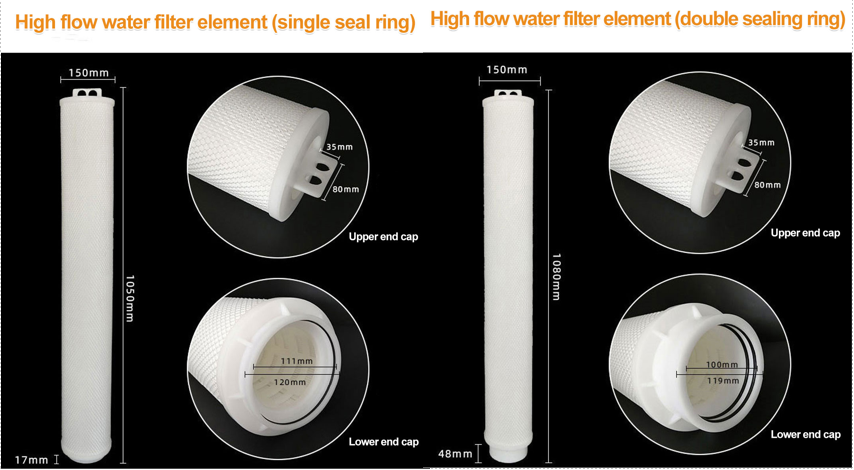

End cap: The end cap is the front and rear parts of the filter element, usually made of durable PP material. The end cap is responsible for channeling filtered water out while preventing unfiltered water and contaminants from escaping. A good end cap design can provide good sealing and prevent water leakage.

0-ring: The 0-ring is located on the surface of the head and is made of special rubber that is resistant to high temperature, acid and alkali, and wear. The role of the 0-ring in the filter element is to provide the necessary sealing and anti-leakage, so that the filter element can maintain stable filtration performance under various environmental conditions.

The above four parts together constitute the large flow filter element, and each part has its unique functions and requirements. Only with the perfect cooperation of all parts can the large-flow filter element exert excellent filtration performance and meet various stringent filtration needs.

The characteristics of high-flow filter elements:

High-efficiency filtration capacity: The most important selling point of the high-flow filter element is its high-efficiency filtration capacity. Using advanced filter material technology, the high-flow filter element can effectively remove small impurities in the water and provide us with a clean water supply source.

High-flow treatment: As the name suggests, high-flow filters can process large amounts of water in a short period of time, which is critical for sites that require large-scale water treatment (such as public facilities, industrial production lines, etc.).

Long-term durability: Through carefully designed internal and external structures and high-quality material selection, the high-flow filter element has excellent durability and stability, reducing the frequency of replacement and lowering maintenance costs.

Wide scope of application: Whether it is a household water supply system or an industrial production environment, the high-flow filter element can exert its excellent performance. Its product lines with different formats and specifications can meet various customized needs.

Environmentally friendly and energy-saving: The large-flow filter element uses physical filtration method and does not require electricity, which is both energy-saving and environmentally friendly. At the same time, clean wastewater can be recycled and used to reduce the waste of water resources.

Classification of high flow filter elements:

length:

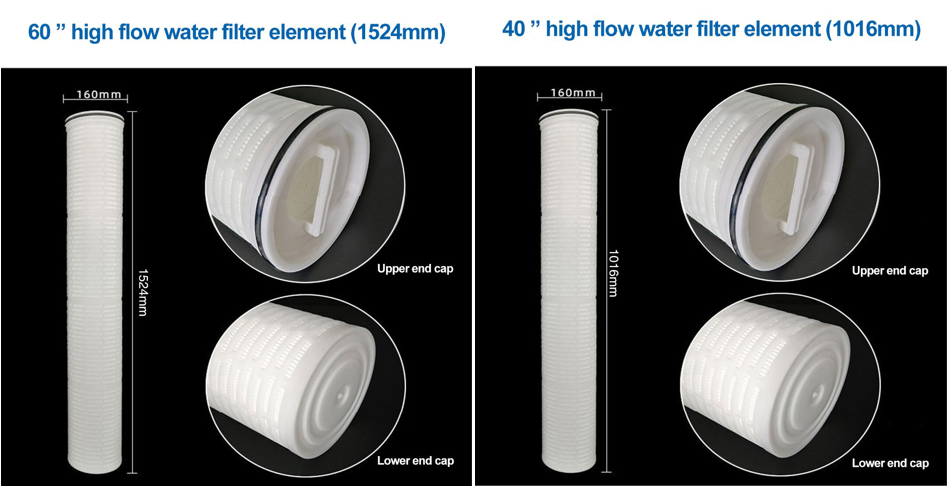

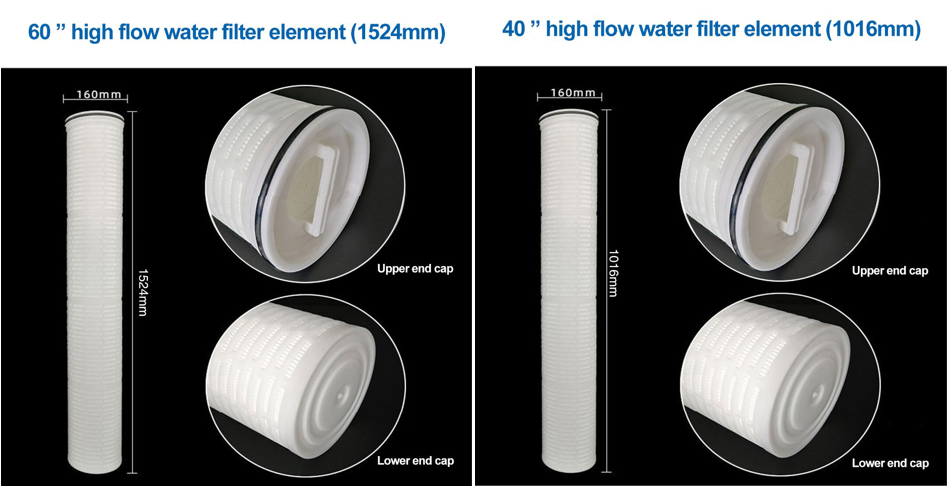

Can be divided into 20″ high flow filter element, 40″ high flow filter element, 60″ high flow filter element

Filter brand:

According to the manufacturer, high-flow filter elements can also be divided into PALL high-flow filter elements, PARKER high-flow filter elements, 3M high-flow filter elements, Pentair high-flow filter elements, etc.

Filter material:

According to the different filter materials, the materials of large flow filter elements mainly include PP, glass fiber, etc.

Filter type:

Some high-flow filters are used to remove solid particles from industrial water, others are used to remove particles from oil.

The production process of high-flow filter elements usually includes the following steps:

1. Injection molding of end caps and outer frames: This is the first step in manufacturing the filter element and involves the injection molding of end caps and outer frames.

2. Polypropylene/glass fiber blanking: Choose high-quality polypropylene/glass fiber as filter material.

3. Use a corrugation forming machine to deeply fold the polypropylene in the order of the supported layer and filter layer.

4. Assembly and bonding of the end cap, frame, and filter layer polypropylene: This step is to assemble and bond the injection molded end cap and frame with the polypropylene filter material.

5. Wait for colloid bonding: This is a time-intensive process that requires waiting for the adhesive to solidify between the various parts of the filter element.

6. Send to the testing center for random inspection: Each produced filter element needs to be quality tested to ensure that it meets the usage requirements.

7. Only when the pass rate reaches 99% or above can it leave the factory: This is part of quality control. Only when it meets a certain pass rate can the filter element be sold and leave the factory.

8. Packaging and shaping: The last step is to package the filter element and prepare it for shipment to the point of sale.

How we control product quality of high flow filter:

Material control: We control quality from the source and conduct strict quality inspections on all incoming raw materials to ensure that they meet the quality standards we set.

Production process control: During the production process, we have strict operating procedures and complete quality inspection links. Unqualified semi-finished products will not enter the next process.

Factory inspection: Before the products leave the factory, we will conduct full inspection or random inspection to ensure that every product leaving the factory is of high quality.

Traceability system: We have established a complete quality traceability system to facilitate traceability of product quality at one time.

Here are some common industries and applications:

Industrial manufacturing:

Parts of use: cooling water systems, flushing and cleaning equipment in the manufacturing process, etc.

Usage: Depending on the size and production needs of the plant, high-flow filters are typically required, such as treating thousands to hundreds of thousands of gallons of water per hour.

Service life: The service life of high-flow filter elements depends on water quality and filter element type, generally ranging from several months to one year.

Achieved results: The large-flow filter element can effectively remove suspended solids, particulate matter, sediment and other impurities, protect equipment from pollution and blockage, and improve production efficiency and equipment life.

Hotel and catering industry:

Parts used: main water source inlet, pre-treatment system, drinking water equipment, etc.

Usage: Depending on the size of the hotel and customer needs, the usage of the filter element will vary, usually to accommodate high water flow requirements.

Service life: The service life of high-flow filter elements depends on water quality and filter element type, generally ranging from several months to one year.

Effect achieved: The large-flow filter element can remove residual chlorine, odor, particulate matter and bacteria in the water, provide clean and safe water source, and ensure the health and satisfaction of guests.

Medical and Laboratory:

Parts of use: water supply system, purified water equipment, etc.

Usage: Hospitals and laboratories usually require high-purity water, so the usage of high-flow filter elements is relatively small, but high-efficiency filtration capabilities are required.

Service life: The service life of high-flow filter elements depends on water quality and filter element type, generally ranging from several months to one year.

Achieved results: The large-flow filter element can remove microorganisms, bacteria, viruses, organic matter and dissolved solids in the water, ensuring the provision of pure, sterile water sources that meet medical and laboratory requirements.

Public facilities and large buildings:

Application parts: water supply systems, cooling towers, etc. in schools, office buildings, shopping malls, etc.

Usage: Depending on the size of the building and daily water consumption, high-flow filters need to be able to meet high-flow requirements.

Service life: The service life of high-flow filter elements depends on water quality and filter element type, generally ranging from several months to one year.

Achieved results: The large-flow filter element can remove impurities, sediments, rust and organic matter in the water, provide a clean and healthy water environment, and maintain the operation of public facilities and user comfort.

Please note that specific applications and usage may vary based on industry and specific needs. Service life is also affected by water quality. When selecting and installing a high-flow filter element, it is recommended to work with a professional water treatment engineer or supplier to ensure the performance and adaptability of the filter element to your specific needs.

Selection of high flow filter elements:

Choosing the right high-flow filter element is very important, as it can improve the operating efficiency of your equipment and reduce subsequent maintenance costs. Here are some important factors you can consider when choosing a high-flow filter element:

Filter element material: Choose the most suitable filter element material according to your filtration needs and working conditions. For example: activated carbon filter element is suitable for removing chlorine, color, taste, etc. in water; PP filter element is more suitable for removing large-size particles and suspended solids in drinking water, electronics industry and chemical industry.

Pore Size: You need to know how large particles are in the liquid you are filtering so you can choose a filter with the appropriate pore size. If the pore size is too large, small particles will pass through the filter element; if the pore size is too small, large particles will block the filter element.

Filtration efficiency: You should choose a filter element with appropriate filtration efficiency based on your filtration requirements (for example, how much impurities you need to filter out) and your flexibility needs (for example, how much time you have available for filtration).

Pressure resistance and corrosion resistance: Depending on your use environment, whether the filter element needs to have a certain pressure resistance and corrosion resistance.

Supplier: Choose a supplier with reliable quality and good after-sales service. They should be able to provide you with detailed information about the filter element, such as the service life of the filter element, cleaning cycle, replacement method, etc., and provide you with any problems you encounter during use. Questions and answers are provided.

Overall, choosing a high-flow filter requires a lot of consideration and making the best choice for your specific needs. If you have any further questions, please feel free to consult us at any time and we will be happy to serve you.

The replacement method of high-flow water filter element:

Although the process of replacing a high-flow water filter element is not complicated, there are some details that need to be paid attention to. Here is a step-by-step description:

Turn off the water source: First, close the water inlet valve to stop the flow of water. This is to prevent water from gushing when you replace the filter element.

Drain the water from the device: After turning off the water source, open the drain valve of the device to drain the water from the device to prevent water from overflowing during replacement.

Open the filter cabin door: For safety reasons, most filter cabins are equipped with a safety lock. After unlocking, open the door.

Remove the old filter element: Grasp the upper end of the filter element and gently pull out the replaced filter element in the direction of removal.

Check the filter element seat: Before installing a new filter element, check the filter element seat for impurities or damage to ensure that the new filter element can be installed correctly and run well.

Install a new filter element: Place the new filter element into the filter element holder. Pay attention to whether the inlet and outlet directions of the filter element are correct and whether the filter element is firmly installed.

Close the filter element door and lock it: After closing the door tightly, install the safety lock.

Turn the water back on: At this point you can open the water inlet valve and start using the new filter element. When using it for the first time, in order to remove possible impurities and air in the filter element, it is recommended to flush it for 2-3 minutes, and then you can use the new filter element normally.

I would like to emphasize that the frequency of filter replacement depends on your usage environment and water quality. Generally speaking, under normal conditions, we recommend replacing the filter element every 6-12 months.

If you encounter any problems during the replacement process, or have any questions about the replacement cycle, you can consult us at any time and we will be happy to help you.

Precautions for using large flow filter elements:

Correct installation: Ensure that the filter element is installed correctly in the equipment. Refer to the equipment manufacturer's instructions to ensure correct position and orientation.

Check the status of the filter element: Check the status of the filter element regularly during use to see if there are any problems such as wear and cracks. If there are any questions or problems, they should be replaced in time.

Avoid using the wrong filter: Make sure the filter you use is suitable for your equipment and the material you need to filter. Using an inappropriate filter element can cause equipment problems and other potential safety risks.

Avoid excessive pressure: Although high-flow filter elements can withstand large operating pressures, excessive pressure can cause structural rupture of the filter element or reduced performance. Therefore, make sure the pressure used is within the manufacturer's recommended range.

Replace regularly: Replace filters regularly according to the manufacturer's recommendations and your specific usage. The filter element cannot be used indefinitely, and its life span depends on many factors such as the filter material and the working environment.

Cleaning: Some types of filter elements (for example, backwash filter elements) can be cleaned and reused, but not all filter elements can be cleaned. For non-cleanable filter elements, attempting to clean them may cause structural damage or reduced performance of the filter element.

Storage: If you have unused filters, they should be stored in a dry, ventilated and dark place. In addition, try to use the filter element within its expiration date.

The above precautions will help you use high-flow filter elements better and safer.