1, the development of reasonable filtration wind speed

Bag dust collector resistance depends largely on the filtration wind speed, the whole structure of the dust collector, dust bag, dust layer resistance will be added with the progress of the filtration wind speed. A pulse bag dust collector, no matter what filter material, its net filtration wind speed should not be 1m/min, on the fine dust layer, because of the dust particles lap each other, then the need for low filtration wind speed, otherwise it will add the dust collector's operating resistance. However, many dust removal equipment manufacturers in the selection of products in order to compete in the market, competitive and regardless of other progress in the filtration wind speed, in order to achieve the intention of reducing the cost of the equipment, this dust collector equipment resistance, will be higher than the normal value.

However, blindly reduce the filtration wind speed, and can not progress in dust removal power, but also may not be able to reduce the filtration resistance, but also may form an uneconomical loss; only in a full understanding of the nature of the dust and the characteristics of the system based on the basis of the optimisation of the structure of the dust collector body planning, the correct economic and technical analysis, in order to reasonably determine the filtration wind speed.

2、Manipulate the rising speed of airflow

Airflow rising speed refers to the activity speed of the flue gas in the dust bag space, airflow rising speed is an important parameter to measure the function of the dust collector structure, the function of the low-pressure pulse bag dust collector has a greater impact. Under the condition of the same processing air volume, the rising speed of the airflow gets big, it is stated that the distance between the dust bag and the bag is small in the space of the useful bag room, the dust bag is placed compactly, and the external dimensions of the dust collector is small, but the rising speed of the airflow is too big, and the operating resistance of the dust collector will be increased accordingly. Normally, the airflow rising speed is controlled at about 1m/s to give full play to the function of the dust collector.

3、Manipulate part of the airflow speed

Part of the airflow speed of the low pressure bag house dust collector includes inlet and outlet wind speed, inlet and outlet valve wind speed, progress valve wind speed, clean air chamber wind speed, flower plate hole wind speed, etc. These wind speeds will have an effect on the resistance of the dust collector. In the process of dust collector planning, we need to try to increase the size of air inlet and outlet, air inlet branch valve mouth and progress valve mouth, in order to reduce the passing speed of airflow, and then reduce the operating resistance of the dust collector. The wind speed of the clean air chamber needs to be completed by raising the height of the clean air chamber, but raising the height of the clean air chamber means that the equipment cost increases, so the wind speed should be selected to have a reasonable scale, under normal circumstances, the wind speed of the clean air chamber manipulation in the 3m/s ~ 5m/s. The wind speed of the flower plate holes and the filter bag LD ratio is proportional to the length of the same diameter of the filter bag length, the longer the length of the flower plate holes, the higher the wind speed. Dust bag L/D ratio is less than 60, otherwise it will not only increase the operating resistance of the dust collector, but also affect the cleaning effect of the dust bag.

4, pre-dusting

Dust collector resistance rising speed and the concentration of dust in the flue gas is related to the size of the flue gas, if the flue gas through the appropriate methods to collect part of the dust, and then filtered by the filter bag for filtration and purification, can reduce the filter load of the dust collector, the resistance rising speed will also decline. There are many methods of pre-dusting, such as: adding a cyclone dust collector in the front of the dust collector or adding cyclone equipment inside the dust collector, through the cyclone centrifugal effect to collect dust to reach the intention of pre-dusting; the downward inlet method of the bag dust collector because the flue gas passes through the dust hopper, because of the sudden expansion of the airflow space, the coarse particles of dust and some of the fine particles of dust will be precipitated, therefore, the downward inlet method is the most recognised method of bagged dust collector in the air inlet. Therefore, the downward air intake method is recognised as the better air intake method in the bag house dust collector.

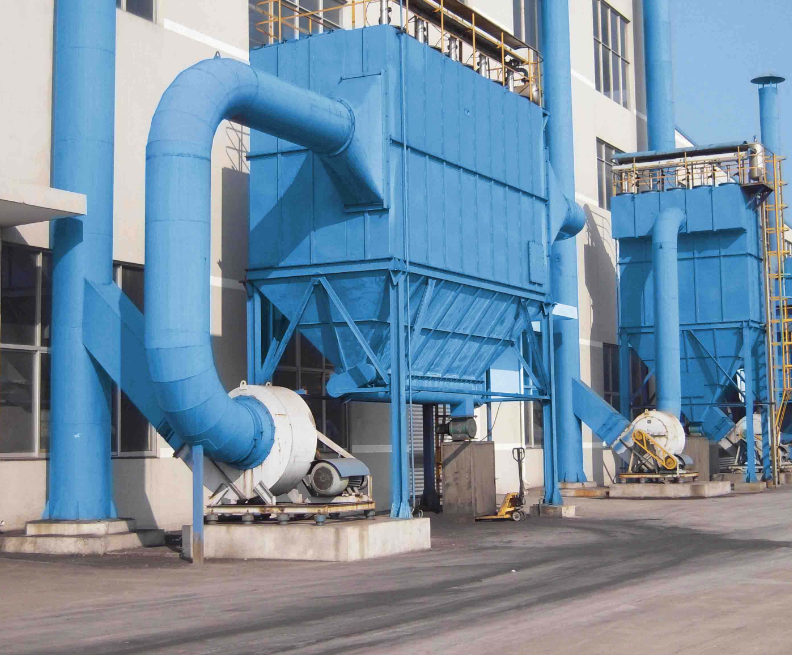

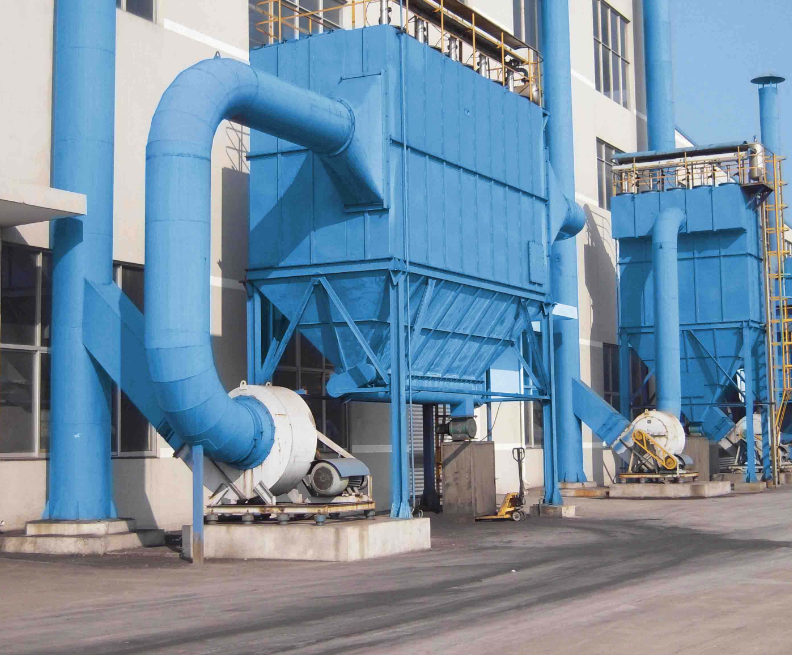

Related Dust Collecting Equipment products:

Baghouse Dust Collector

Cartridge Dust Collector

Self-cleaning Air Filter