CUSTOMIZATION SERVICE PROCESS

Provide customization services according to different working conditions

Working principle

The wire wound filter element is formed by winding the textile fiber on the multi skeleton in a specific way. When winding, the filter elements with different filtering precision can be made by controlling the winding density of the filter elements. The filter element has a large outside diameter and a small inside diameter, which has an excellent deep filtering effect.

Advantages

Large filter area;

Large filter area

High filtering precision:

Relative filtration accuracy, the retention rate is more than 90%, A wide range of filtration precision can meet various application requirements, with good pollution interception effect and longer service life.

Internal thread structure;Enhanced compression resistance;

Internal thread structure for enhanced compression resistance:

Wide chemical compatibility, large flux, low differential pressure, Can be washed and regenerated, economical, Sterilize by chemical method, in-line steam sterilization.

Polypropylene composite filter membrane

Food grade material

Filter media: polypropylene fiber membrane Upper and lower flow support material: polypropylene Support frame and structural elements:Polypropylene Sealing material: silicone rubber, nitrile rubber, EPDM rubber, fluorine rubber.

Structure

Structure:

Sparse outside and dense inside, honeycomb structure, Large amount of pollution.

Technical parameter

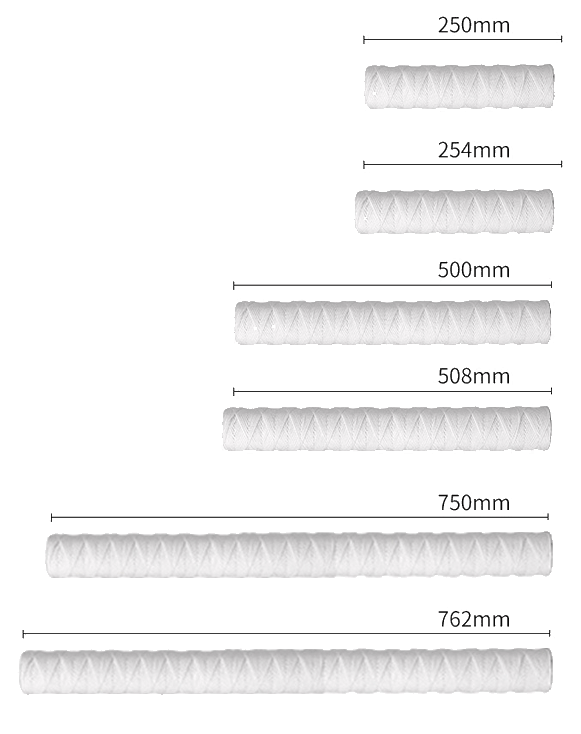

Name: Wire wound filter element Filter Length:10″,20″,30″,40″

Filter Outer Diameter:Φ60mm,Φ65mm; Filter inner diameter:Φ28mm,Φ30mm;

Central frame: polypropylene PP frame, stainless steel frame; Maximum pressure: ≤0.5MPa; maximum pressure drop: 0.2MPa.

Filtration accuracy:1μm,5μm,10μm,20μm,30μm,50μm,75μm,100μm; Filter material: polypropylene PP thread, absorbent cotton thread, glass fiber thread

Maximum working temperature: polypropylene thread: polypropylene frame≤60°C; stainless steel frame≤80°C. Absorbent cotton thread: stainless steel frame≤120°C.

Can be customized according to different working conditions

Product details

Pictures

Product details

Video

Cases

Application: security filter elementFlow: 20t/h

Application: Circulating water treatmentFlow: 20t/h

Uses: security filter circulating water treatmentFlow: 200m3/h

Provide customization services according to different working conditions

Professional installation team to ensure the normal operation of the equipment

Technical Support