The refrigeration filter cartridge effectively intercepts impurities such as metal debris, oil stains, and moisture in the refrigeration system through precise filtration technology. With excellent filtration performance and long - life design, it becomes a key component to ensure the stable operation of refrigeration equipment.

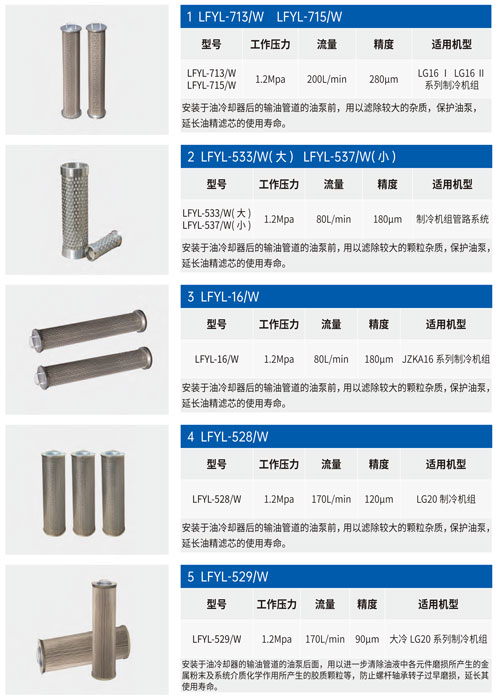

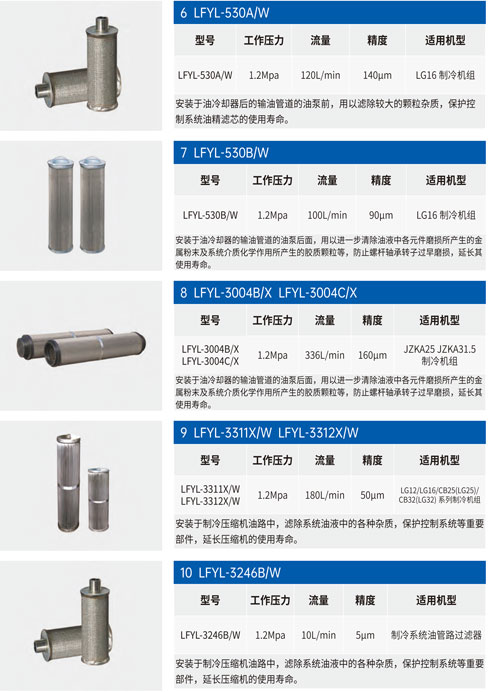

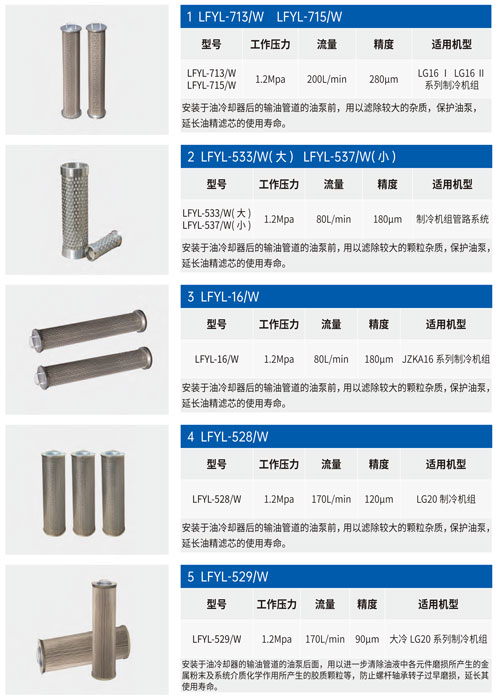

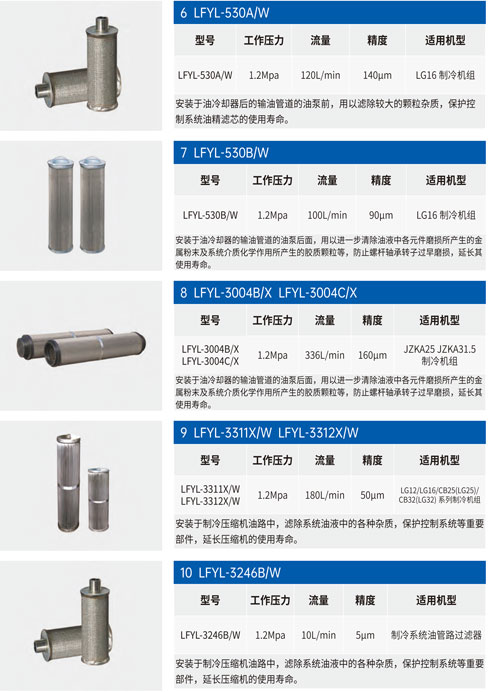

The filter element of the refrigeration filter is installed in front of the oil pump on the oil pipeline after the oil cooler, to filter out larger impurities, protect the oil pump and extend the service life of the oil fine filter element.

Refrigerant Circulation Inflow: The refrigerant carrying impurities enters the filtration chamber through the cartridge inlet with the system circulation.

Multi - layer Interception Filtration:

Primary Interception: The outer metal mesh initially intercepts larger particles, such as welding debris and rust.

Deep Purification: The middle - layer adsorption material absorbs moisture, acidic substances, and tiny metal particles.

Fine Filtration: The inner polymer filter material intercepts micron - level impurities, ensuring the purity of the refrigerant.

Clean Output: The refrigerant after three - stage filtration flows out from the cartridge outlet and re - enters the refrigeration cycle system.

Blockage Warning and Replacement: When the pressure difference across the cartridge exceeds the set threshold (e.g., 0.1MPa), the system issues a warning. The equipment needs to be shut down in a timely manner, and the cartridge should be replaced to maintain refrigeration efficiency.

| Key Advantages | Description |

|---|

| High - precision Filtration | Filtration accuracy ranges from 5 - 25μm, effectively intercepting metal particles, oil stains, etc., with an interception rate ≥99%. |

| Efficient Water Absorption and Acid Removal | Built - in adsorbents such as molecular sieves and desiccants quickly absorb moisture in the refrigerant and neutralize acidic substances, preventing ice blockages and equipment corrosion. |

| Long - life Design | Adopts high - strength corrosion - resistant housing and fatigue - resistant filter materials, with a service life of over 5 years under normal conditions, reducing replacement frequency. |

| Low - resistance Energy - saving | Optimized fluid channel structure, with an operating pressure drop <0.05MPa, reducing compressor energy consumption and saving operating costs. |

| Standardized Adaptability | Complies with international standards such as ISO and ASHRAE, is suitable for various refrigeration equipment, and supports customized sizes and filtration accuracies. |

| Industry | Application Scenarios | Core Value |

|---|

| Air Conditioning and Refrigeration | Domestic air conditioners, commercial central air - conditioning systems | Prevents compressor wear, improves refrigeration efficiency, extends equipment service life, and reduces maintenance costs. |

| Cold Chain Logistics | Cold storage, refrigerated truck refrigeration units | Ensures stable low - temperature environments, avoids refrigeration failures caused by impurities, and guarantees the safety of fresh food storage. |

| Industrial Refrigeration | Chemical and pharmaceutical industry freezing equipment | Maintains the stable operation of the refrigeration system, ensures production process accuracy, and avoids equipment failures and safety hazards caused by impurities. |

| Transportation | Automobile air conditioners, high - speed train refrigeration systems | Improves refrigeration effect, reduces maintenance frequency, and optimizes passenger comfort and equipment reliability. |

How often does the refrigeration filter cartridge need to be replaced?

The replacement cycle depends on the usage environment and frequency, generally 1 - 3 years. If the equipment experiences reduced refrigeration efficiency, abnormal compressor noise, or a pressure difference exceeding 0.1MPa, replacement is required.

Can the cartridge filter moisture in the refrigerant?

Yes. The cartridge is equipped with high - efficiency water - absorbing materials (such as molecular sieves), which can effectively adsorb moisture in the refrigerant and prevent ice blockages and system corrosion.

Can filter cartridges of different brands be used interchangeably for refrigeration equipment?

Cartridges need to be matched according to equipment models, refrigerant types, and system parameters. It is recommended to give priority to original factory specifications or certified compatible models.

The refrigeration filter cartridge has become the core guarantee for the normal operation of refrigeration equipment, thanks to its efficient filtration and stable durability. Whether for daily household air conditioners or large - scale industrial refrigeration systems, reasonable selection and maintenance can effectively improve equipment performance and reduce failure rates. In the future, with the development of refrigeration technology towards energy - saving and intelligentization, filter cartridges will continue to optimize material and structural designs, providing more reliable filtration solutions for the industry.

If you are interested in this product or have any questions, please feel free to contact us at any time.

1.Reverse Osmosis Equipment

2.Demineralized water equipment