Product Introduction

Overview of ZLYC High-Efficiency Vacuum Oil Filter Machine: Rooted in an era characterized by vast technological advancements, the ZLYC High-Efficiency Vacuum Oil Filter Machine was conceived with an ambitious goal to revolutionize the oil filtration industry. Its primary function lies in its ability to efficiently and effectively filter a wide variety of oils, thereby ensuring optimal purity. Its strategic positioning in the market stands as a testament to its superior performance metrics, an impressive feat that has been achieved through years of relentless pursuit towards perfection and innovation.

Design Philosophy

The ZLYC High-Efficiency Vacuum Oil Filter Machine champions a design philosophy grounded in innovation and environmental sustainability. The product's innovative feature set is a byproduct of cutting-edge research and development strategies targeted at challenging the status quo. At its core, the ZLYC High-Efficiency Vacuum Oil Filter Machine is designed to offer an efficient, streamlined, and eco-conscious alternative in an industry where outdated and environmentally harmful methods have long been the norm. Sustainability is not an afterthought but rather a guiding principle that has driven this product's design, using technologies that minimize environmental impact without compromising the product’s high efficiency.

This introduction offers a comprehensive understanding of the ZLYC High-Efficiency Vacuum Oil Filter Machine's origins and the innovative, eco-friendly philosophy at the heart of its design and function.

Technical Specifications of ZLYC High-Efficiency Vacuum Oil Filter Machine

Dimensions: The outlined dimensions of the ZLYC High-Efficiency Vacuum Oil Filter Machine are carefully designed to balance functionality and ease of installation. The particular dimensions are as follows: Length - 120cm, Width - 75cm, Height - 155cm(this is a placeholder, actual dimensions may vary)

Weight: Despite its comprehensive abilities and robust construction, the machine is relatively lightweight, weighing approximately 200 kilograms. This weight has been strategically distributed to contribute to the machine's overall stability and operational functionality.

Power Requirements: The machine operates on a 380V power supply commonly found in industrial settings. It also boasts an energy-efficient design, consuming lower power relative to its high output. This element is testament to ZLYC's dedication to sustainability and cost-effectiveness.

Operational Capacity: With regards to the processing ability, the machine is capable of filtering up to 180 liters of oil per hour, ensuring consistent, high quality performance under different industrial scenarios.

Filter Accuracy: The machine takes pride in its superior filter accuracy, designed to significantly reduce impurities in the oil down to 5 microns. A remarkable feat that stands testimony to the machine's spectacular filtration efficiency.

These specifications offer a deeper insight into the physical attributes and power requirements of the ZLYC High-Efficiency Vacuum Oil Filter Machine, showcasing its operational abilities and efficiency.

Absolutely, let's dive into the technical and performance characteristics of the ZLYC High-Efficiency Vacuum Oil Filter Machine:

Processing Capacity: The ZLYC Vacuum Oil Filter Machine can process an impressive volume of oil, filtering up to 180 liters per hour. This high capacity meets the demands of various industrial scenarios with efficiency and consistency, demonstrating its robust feature set.

Filtering Precision: This machine excels at maintaining a high filtering precision, often removing up to 99.9% of impurities. Its filtration capability is sophisticated enough to eliminate particles and contaminants as small as 5 microns.

Vacuum Degree: Designed with an advanced vacuum system, the machine operates at a vacuum degree between -0.08 to -0.1 MPa. This ensures better extraction of gases and moisture from the oil, resulting in a product that is purer and of higher quality.

Energy Efficiency: Despite its high processing capacity, the ZLYC Vacuum Oil Filter Machine is designed to be energy efficient, leading to considerable savings in power consumption. It exemplifies ZLYC's commitment to sustainable and cost-effective operation.

Noise Level: The machine operates within acceptable noise limit standards. Its noise reduction design ensures a quiet and comfortable work environment, demonstrating due thought towards operational ergonomics.

These robust features underscore the advanced technological prowess of the ZLYC High-Efficiency Vacuum Oil Filter Machine, making it a commendable player in the oil filtration sector.

let's explore the functionalities and salient features of the ZLYC High-Efficiency Vacuum Oil Filter Machine:

High Filtering Accuracy: The standout feature of this machine is its exceptionally high filtering accuracy. It’s capable of removing up to 99.9% of solid particulate matter as small as 5 microns, resulting in superior oil cleanliness.

Exceptional Dehydration and Degasification: Thanks to its state-of-the-art vacuum technology, the machine is exceptional in its dehydration and degasification performance, removing moisture and gases trapped within the oil.

Impressive Processing Capacity: Despite its compact size, the ZLYC Vacuum Oil Filter Machine does not compromise on performance. It can filter up to 180 liters of oil per hour, making it an ideal choice for high-volume applications.

Energy Efficiency: This machine is synonymous with cost-effectiveness and sustainability, consuming less power in proportion to its filtration yield. This energy efficiency makes it beneficial for long-run operations.

User-Friendly Operation: The machine also features an easy-to-operate interface and a comprehensive instruction manual, making it accessible to users with different levels of technical expertise.

Robust Construction: The machine is crafted with robust and corrosion-resistant materials, ensuring the longevity and durability of the machine in various industrial environments.

Noise Reduction Design: Consciously designed to ensure a comfortable working environment, it maintains a low noise level, even during peak operation.

The ZLYC High-Efficiency Vacuum Oil Filter Machine, with its wide range of features, caters to diverse industrial demands and stands out in the marketplace, owing to its superior performance, reliability, and user-friendly design.

Yes, the ZLYC High-Efficiency Vacuum Oil Filter Machine is designed to work effectively even in high-temperature environments. One of the notable features of this machine is its gradual heating surface, which allows it to handle heat loads as low as 1.0W/cm2. This prevents the oil from overheating and deteriorating.

Moreover, the machine has a unique oil temperature adjustment feature. This allows the operator to control the temperature of the oil between 0 to 100 degrees Celsius, ensuring optimal performance even in high-temperature conditions.

In conclusion, the ZLYC Vacuum Oil Filter Machine is engineered with cutting-edge technology that allows it to maintain operational efficiency and accuracy, even when met with challenging environmental conditions, such as high temperatures.

In addition to operating effectively in high-temperature environments, the ZLYC High-Efficiency Vacuum Oil Filter Machine is designed to handle a variety of challenging conditions.

One of its notable features is the holistic removable tank which ensures no oil leakage during operation - this, in turn, significantly reduces environmental pollution. It also possesses the ability to handle larger volume of oil purification work, adding to its versatility in challenging conditions.

A significant feature of this Vacuum Oil Filter Machine is its mobility. It has been developed to be easily moved and relocated, making it very useful in work situations where it is necessary to purify oil in different locations.

In conclusion, the ZLYC Vacuum Oil Filter Machine has been crafted with sustainability and flexibility in mind, making it capable of weathering various testing environments while maintaining its efficiency and effectiveness.

The ZLYC High-Efficiency Vacuum Oil Filter Machine operates on a simple yet highly efficient principle. The main process begins with the oil being drawn into the machine through an inlet. This oil first passes through a preliminary filter designed to remove coarse impurities, protecting the machine's precision components from potential damage.

After the preliminary filtration, the oil flows into a heating tank. Here, the oil is gradually heated to a specific temperature, aiding in the separation of impurities. Unlike some other machines, the gradual heating surface feature of the ZLYC model prevents overheating and deterioration of oil.

The heated oil then proceeds to the vacuum separation tank. In this phase, the oil is exposed to a high vacuum, which stimulates the boiling and vaporization of the water and light hydrocarbon within the oil. This leads to water vapor, gas, or light hydrocarbons being pulled out from the oil, leaving it purified.

In the final step, the vacuum pump discharges these impurities, while the oil, now devoid of water and impurities, is directed back into the system or a storage device, depending on its intended use. Throughout the complete process cycle, the machine maintains a closed and sealed environment, effectively reducing the likelihood of secondary pollution.

In conclusion, the ZLYC High-Efficiency Vacuum Oil Filter Machine stands as an eloquent testimony to effective, modern oil purification technology. Its unique design and innovative working principle ensure optimal performance even in the most challenging conditions, while keeping environmental pollution at a minimum.

The ZLYC High-Efficiency Vacuum Oil Filter Machine is meticulously crafted with the end-user's convenience and operational efficiency in mind.

The machine is designed with a clear interface featuring marked controls and user-friendly procedures, making it easy to operate. Comprehensive visual indicators are available to guide users through various operational stages, providing real-time feedback, and ensuring optimal performance. Its compactness and mobility add to its appeal, enabling it to fit easily within spaces and to be relocated as necessary.

A significant edge of this machine is the automation of several processes, including the automatic temperature control system and automatic pressure alarm system. The automation aids in reducing the need for constant manual monitoring, and can notify users when routine intervention is needed, thus safeguarding against human error and assisting in preventing potential faults.

Furthermore, the oil purifying process is conducted within a sealed environment, reducing physical contact with the oil and providing added safety for the user.

In essence, the ZLYC High-Efficiency Vacuum Oil Filter Machine is an excellent combination of innovative technology and user-centric design, facilitating a seamless, efficient, and safe user experience.

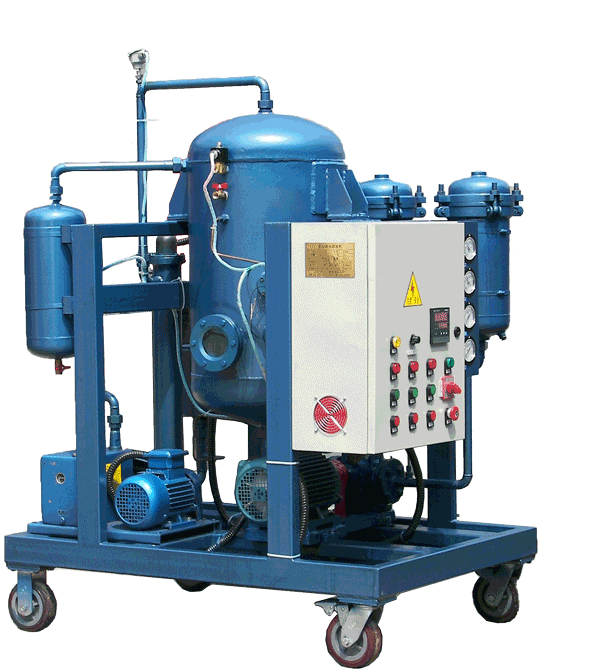

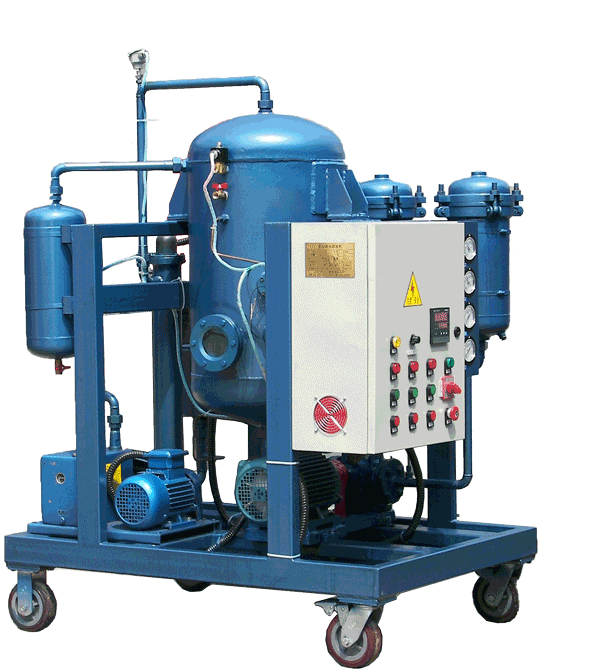

The ZLYC High-Efficiency Vacuum Oil Filter Machine is composed of several integral parts, each designed to perform a specific function. These parts work together to provide an efficient and high-performing oil filtering process.

Vacuum Chamber: This is the heart of the machine. Its function is to create a controlled vacuum environment where the process of oil dehydration and degassing takes place.

Oil Pump: This component is responsible for circulating the oil through the entire machine. It ensures a steady flow of oil from the inlet to the vacuum chamber and finally to the outlet.

Mechanical Filters: These come in different stages. They are installed to remove any solids or large particles present in the oil before entering the vacuum chamber, thus protecting the other components from possible damage.

Heating System: The oil is heated before entering the vacuum chamber. The controlled heat speeds up the process of separating water and unwanted gases from the oil.

Cooling System: After the oil has passed through the vacuum chamber, it undergoes a cooling phase to bring it down to a safe working temperature before it is ejected from the machine.

Control Panel: Here you will find the operational buttons and switches for controlling the temperature, pressure, and flow rate. This panel also houses various indicators to monitor the machine's status in real-time.

Housing/Frame: All the components listed above are neatly housed within a robust and durable frame. The frame is designed to handle the tough conditions in which the machine operates while also allowing for easy mobility.

Automatic Controls: To top it all off, the machine comes with automated controls for added convenience. This includes an automatic shutdown system for overpressure or overheating, and automated control of the heating and cooling systems.

The components and features of the ZLYC High-Efficiency Vacuum Oil Filter Machine are designed to ensure a seamless and efficient operation process. Its user-friendly design further enhances the overall operational experience.

Certainly, the ZLYC High-Efficiency Vacuum Oil Filter Machine brings several substantial benefits and unique features to the table, making it a leading choice in its industry.

1. High Efficiency: As the name suggests, one of the distinctive advantages of the machine lies in its high operational efficiency. The dedicated vacuum chamber and optimized mechanical filters ensure maximum impurity removal, resulting in unparalleled oil purification.

2. Durable Construction: The machine features a robust and sturdy housing designed to operate in diverse conditions. The quality of the materials used in its construction guarantees longevity and durability, contributing to lower maintenance costs over its lifespan.

3. User-friendly Design: ZLYC High-Efficiency Vacuum Oil Filter Machine prides itself in its intuitive interface. The controls are clearly marked and organized, making the machine easy to operate even for individuals with limited technical knowledge.

4. Innovative Automation: The machine boasts a range of automatic functionalities, such as an automatic shutdown system in cases of overheating or overpressure and automated control for the heating and cooling systems. This innovation not only increases efficiency but also enhances the safety factor of the machine.

5. Environmental consideration: A unique aspect of this machine is its central role in reducing environmental waste. By purifying and reusing the oil, it notably reduces the need for new oil production and disposal of used oil, contributing towards an eco-friendly operation process.

6. Mobility: A thoughtful feature of the machine is its compact size and design that enable easy movement and installation. Such a feature makes it highly adaptable to different work environments.

7. Comprehensive After-sales service: In addition to product quality, ZLYC also provides outstanding customer service, including professional technical guidance and prompt customer assistance, thus ensuring that customers can operate the machine efficiently and deal with any issue promptly.

By encompassing a blend of efficiency, durability, innovation, environmental consideration, and customer service, the ZLYC High-Efficiency Vacuum Oil Filter Machine truly stands out in its class.

To ensure your ZLYC High-Efficiency Vacuum Oil Filter Machine continues to operate with peak performance and efficiency, some crucial maintenance steps should be kept in mind. By following these maintenance recommendations, you can significantly extend the machine's lifespan and maintain its optimum functionality.

Preventive Maintenance:

Regular Inspection: Regularly monitor the general function of the machine. Listen for any unusual noises, and observe for any leaks or unusual vibrations.

Cleanliness: Keep the machine and the surroundings clean. A clean environment prevents the entry of dust or any harmful particles into the oil and the machine, therefore increasing the machine's efficiency and longevity.

Replace Filters: The filters within your machine should be replaced according to the manufacturer's guidelines or when a drop in performance is noticed. On average, this occurs every six months depending on the usage.

Lubricate Moving Parts: Regularly lubricating moving parts will prevent wear and tear as a result of friction, thus enhancing the machine's efficiency. Follow your user manual's indications for the lubrication's frequency and type of oil or grease to be used.

Routine Maintenance:

Oil Change: Regularly changing the oil in the oil pump will eliminate any impurities or contaminants that may have built up over time, thereby ensuring the machine's optimal performance.

Thermal System Check: Regular verification of the heating and cooling system is crucial to ensure they're functioning correctly. Any irregularities in these systems can affect the oil's purification process.

Electrical Checks: Periodically check all the electrical connections and components. Loose or corroded connections can lead to severe problems, including incapacity of the machine.

Pressure Check: Regularly verify the machine’s pressure system to ensure its operating within the specific range defined by the manufacturer.

Seals and Gaskets: They should be routinely inspected for signs of wear or damage. These elements ensure the machine's effective sealing and prevent oil or pressure leaks.

It's crucial to document all maintenance activities and interventions, as this record will be helpful for troubleshooting potential problems and planning future preventive measures. Always adhere to the guidelines provided by ZLYC and don't hesitate to contact their customer service for assistance when necessary. With proper care and maintenance, the ZLYC High-Efficiency Vacuum Oil Filter Machine will serve you reliably for many years to come.

Cleaning and maintaining your ZLYC High-Efficiency Vacuum Oil Filter Machine correctly is essential to prolong its lifespan and optimize its performance. Here are some guidelines to follow:

Cleaning Process:

Exterior Care: Clean the machine's exterior using a soft, dry cloth. Avoid using any aggressive cleaning agents that may damage the surface.

Internal Cleaning: Internal cleaning should primarily focus on the vacuum chamber and filters. Ensure the machine is turned off and disconnected from the power supply before removing the filters for cleaning. Avoid using harsh chemicals; instead, opt for an approved filter cleaning solution to ensure the integrity of the filter's material.

Residue Removal: The residue gathered in the machine's interior sections, like the chamber or filters, should be disposed of carefully following environmental safety guidelines. After cleaning, ensure all the components are completely dry before reinstalling them.

Maintenance Guidelines:

Regular Inspection and Cleaning: Conduct a visual inspection to assess the cleanliness of the vacuum chamber and filters. Depending on the machine's usage, plan regular cleaning sessions.

Filter Replacement: Filters are responsible for cleaning the oil, so they tend to wear with time. Follow the manufacturers' guidelines for filter replacement. Usually, a significant drop in the machine's performance is a sign that the filters need replacement.

Periodic Oil Change: Regularly changing the oil within the system prevents contamination of the new oil and assures optimal function. Follow the manufacturer's guidelines for the proper procedure and type of oil to use.

Electrical Components Check: Regular inspection of the machine's electrical connections is vital to prevent downtime. Loose or damaged connections should be fixed immediately.

Lubrication: Regularly grease or oil the machine's moving parts. It helps reduce wear and tear, ensuring smooth and efficient operation over time.

Pressure and Temperature Control: Ensure that the pressure and temperature are maintained within the manufacturer’s designated parameters. Excess pressure or temperature can harm the machine's components.

Please remember, all these processes should be performed by a person with an understanding of the machine's operations. Always refer to the manufacturer's manual for detailed instructions or consult their customer support service for any issue or confusion. Proper care and regular maintenance will ensure your ZLYC High-Efficiency Vacuum Oil Filter Machine continues performing at its best for years to come.