Why the LYC-J Series Coalescence Dehydrated Oil Filter can Prolong Equipment Lifespan ?

The answear is LYC-J Series Coalescence Dehydrated Oil Filter extends the lifespan of equipment by effectively removing water, gas and impurities from oil. Through its advanced filtration and dehydration process, it can prevent corrosion, improve the performance reliability and durability of the equipment, reducing machine downtime and maintenance costs over time.

Introducing the LYC-J Series Coalescence Dehydrated Oil Filter, a state-of-the-art product from Xinxiang Lefilter Filter Corporation. This multifunctional machine is designed uniquely to combine precision filtration and efficient dehydration, making it a standout piece of equipment in the filtration industry.

Designed thoughtfully for application versatility, our LYC-J series coalescence dehydrated oil filter integrates precision filtration and high efficiency dehydration which aids in the removal of particle impurities and excess moisture from oils. Simultaneously, it also ensures the safeguarding of machinery and devices, thereby increasing their lifespan and promoting efficient operation.

The LYC-J Series operates on a high efficiency particulate filter system, which includes a large filtration area design to effectively filter out impurities in the oil. The coalescence dehydration oil filter has a five-stage filtration system, integrating precision filtration and efficient dehydration to safeguard the functionality of your equipment.

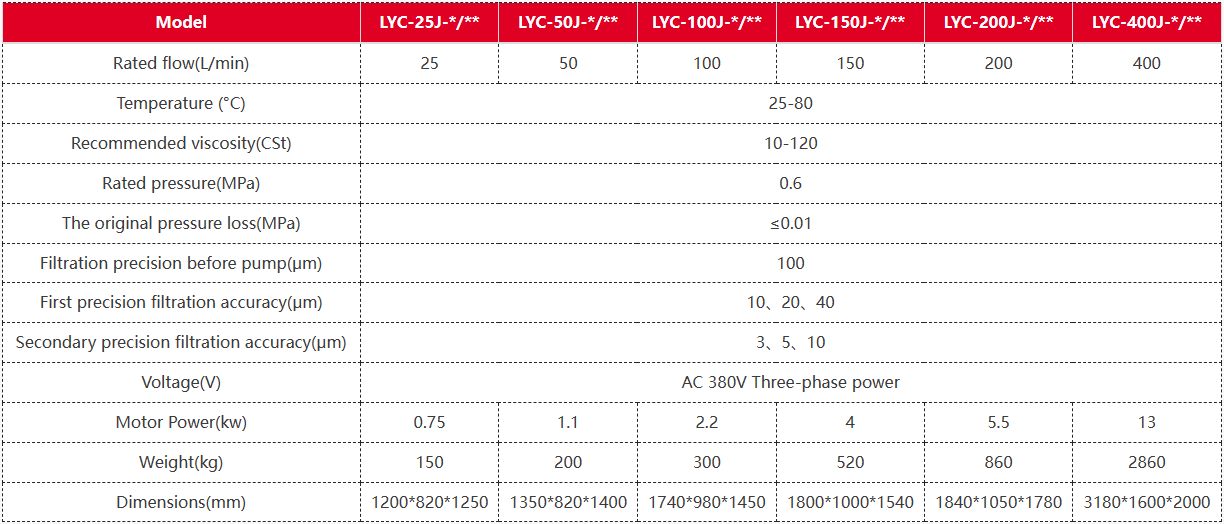

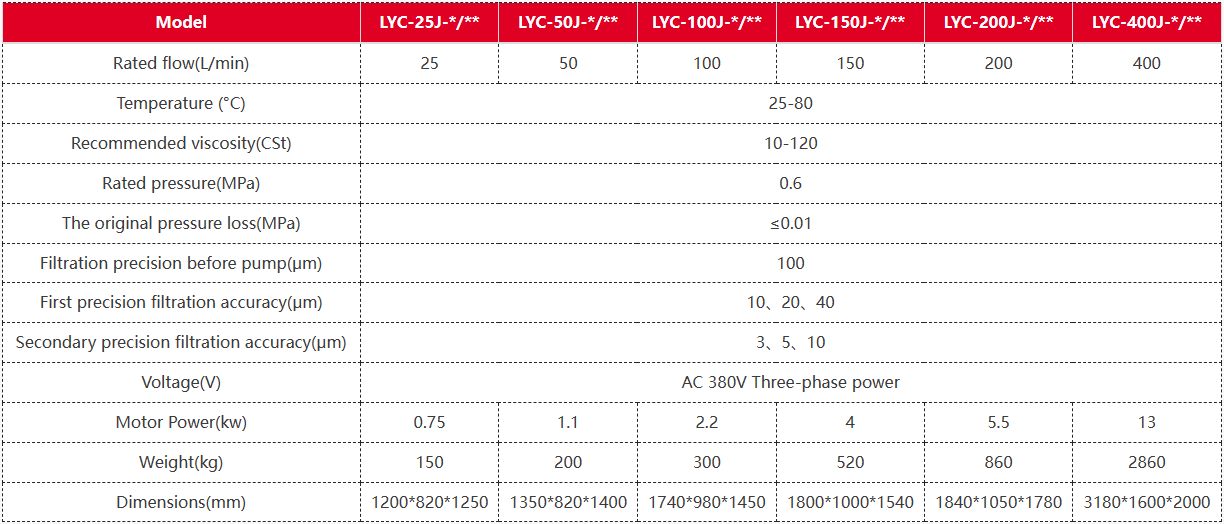

Recommended for oils with a viscosity range of 10-120 CST, it operates with a rated pressure of 0.6 MPa thereby minimizing original pressure loss. Its operating temperature ranges from 5℃ to 80℃, catering to a variety of environments and performance requirements.

Our LYC-J Series Dehydrated Oil Filter is a filtration product designed with a customer-centric approach. We understand the varying requirements of different industries, and as such the LYC-J Series is applicable across diverse sectors like heavy machinery, petroleum, food and beverage among others.

Investing in the LYC-J Series is not just an equipment enhancement, but a commitment to longevity and operational efficiency. It supports the functionality of systems and machinery by ensuring that they run on clean and moisture-free oil, guaranteeing unhampered operation and reduced downtime.

This coalescence dehydrated oil filter stands as a testament to Xinxiang Lefilter Filter Corporation's dedication to providing innovative and highly efficient filter solutions.We welcome you to experience the difference with our LYC-J series coalescence dehydrated oil filter. Making the smart choice today can set a path for assured and efficient operations for tomorrow.

Applications:

1.Heavy Machinery Industry: In heavy-duty machinery, minute impurities can lead to significant issues over time. The LYC-J Series improves the operational efficiency of this equipment by filtering out any impurities, protecting the machine parts from potential damage, and reducing the frequency of overhaul and maintenance.

2.Petroleum and Chemical Industry: Ensuring the purity and quality of petroleum and chemical products is paramount. It's here where the LYC-J series is proving valuable. It can effectively remove particle impurities and moisture from petroleum and chemical products, maintaining their quality and ensuring smooth operations.

3.Power Industry: In power plants and substations, the LYC-J Series aids in maintaining the efficiency of the insulating oil in transformers and circuit breakers by removing moisture and impurities, thus reducing downtime and enhancing electricity generation.

4.Metallurgical Industry: In steel-making processes, hydraulic fluid is pivotal. With our LYC-J series, contaminants and moisture are removed effectively, enhancing its efficiency, and ensuring a high-quality end product.

5.Food and Beverage Industry: Cleanliness and hygiene are vital in this industry. The LYC-J Series ensures the purity of the oil used in food processing machines, contributing to safe manufacturing and packaging process.

6.Automotive Industry: For vehicles, clean oil directly affects engine performance. The LYC-J Series keeps the engine oil free from any moisture and impurities, thereby increasing the lifespan of the engine and enhancing vehicle performance.

7.Ships and Marine Industry: In marine diesel engines, hydraulic units, and lubrication systems, the LYC-J series effectively removes impurities and water content from oil, ensuring the smooth functioning of maritime operations.

The aforementioned industrial applications only scratch the surface of where LYC-J Series Coalescence Dehydrated Oil Filter can contribute. Ultimately, wherever there's a requirement for oil filtration and dehydration, the LYC-J series serves as an innovative and efficient solution. This versatile product, with its wide array of applications, stands as a testament to the adaptability and innovative nature of Xinxiang Lefilter Filter Corporation.

Advantages:

1.High Precision Filtration: The LYC-J Series features a high-efficiency particulate filter system, guaranteeing the removal of the minutest degree of impurities, thus delivering clean and safe oil for smooth machinery operation.

2.Efficient Dehydration: The integrated coalescing separation system ensures the effective removal of moisture from the oil. This prevents the premature wear and tear of equipment, extending its service life and operational efficiency.

3.Versatility: Constructed for universal application, the filter is found to be effective in a wide range of sectors. From heavy machinery, petrochemical, and food industries to transport and maritime sectors, its versatility is its strength.

4.Temperature Resilience: The LYC-J Series operates effectively within a broad temperature range, from 5℃ to 80℃, making it suitable for industries functioning in diverse climates and operational environments.

5.Durability: This series is built to last, featuring a robust and rugged design that stands up to tough operating conditions. This durability translates into cost savings from reduced maintenance and replacement needs.

6.Environmentally Friendly: The filter prolongs the life of the oil, meaning less waste and reduced environmental impact. This aligns with the increasing focus on environmentally-conscious practices in industries worldwide.

7.Easy to Use: The LYC-J Series is designed for operational ease and simplicity. Requiring negligible manpower, this product is epitomized by user-friendly design and easy maintenance.

8.Cost-Efficient: The LYC-J Series provides an economic advantage by decreasing the frequency of oil changes, minimizing equipment downtime, and extending the lifespan of machinery, which reduces overall operational costs.

In sum, the LYC-J Series Coalescence Dehydrated Oil Filter brings significant benefits to businesses, with its ability to safeguard machinery, optimize operations, and contribute to more sustainable practices. T With the LYC-J series, businesses across dimensions can look forward to achieving enhanced operational efficiencies and environmental friendliness for an assured path to sustainable growth.

The filtration process is a step-by-step sequence:

The LYC-J Series Coalescence Dehydrated Oil Filter operates through a complex system to deliver superior performance. Let's explore how each individual part contributes to the entire process of filtration and dehydration.

1.Particulate Filter System: This high-efficiency filter media used in this system possesses a large filtration area. It effectively filters out impurities present in oil, even at a very fine level. This ensures that the oil being output is of the highest quality and free from contaminants.

2.Coalescence and Separation System: Here's where the dehydration takes place. The coalescence process utilizes a filter to combine minute water droplets present in the oil into larger droplets. Once the water droplets are large enough, they separate naturally from the oil due to gravity, hence the term "separation". This system successfully removes any moisture that is present in the oil.

3.Oil Output System: This is the final stage where the purified and dehydrated oil is expelled. Only after passing through the above stringent steps does the oil qualify to be dispatched. This ensures that only the finest quality oil, free of impurities and moisture, is released, guaranteeing the smooth functioning of your machinery or equipment.

Apart from these, there may be other essential components like Inlet/Outlet Ports, for managing the entry and exit of the oil, and Pressure Control Mechanisms, to maintain the adequate pressure inside the machine for optimal performance.

The LYC-J Series Coalescence Dehydrated Oil Filter operates using a systematic and multi-level procedure to ensure the delivery of the purest, moisture-free oil. Each component of this system plays its unique part in ensuring this process is carried out smoothly and effectively. From entry, through processing, to the eventual delivery, each part in this filtration system ensures optimal performance towards achieving a single goal: providing clean and pure, dehydrated oil for your machinery and equipment.

"How is the filtration efficiency of this oil filter?"

The LYC-J Series Coalescence Dehydrated Oil Filter is renowned for its high filtration efficiency. This machine has an integrated system that combines five stages of filtration and powerful dewatering capabilities, ensuring precise filtration and efficient dehydration in one thorough process.The LYC-J Series adopts a high-efficiency filter media, which has an extensive filtration area design. This design allows it to filter out an array of extremely small grain impurities effectively. As a result, this offers a substantial boost to its filtration efficiency.

Additionally, the oil filter system optimizes the oil's cleanliness level to NAS6 or even higher. This indicates that the system can filter solid particles in the oil down to a size of approximately 5 micrometers, providing you with highly purified oil that meets stringent standards.

By utilizing the advanced concept of coalescing separation, it effectively removes particle impurities and water from the oil. This is achieved through the process of merging microscopic water droplets in the oil, which then separate due to gravity.The rated pressure for the LYC-J Series is 0.6 MPa, while the original pressure loss is less than or equal to 0.01 MPa, signifying minimal pressure drop and thus higher filtration efficiency.

Technical parameters:

Step FivProduct Use, After-sales Service:

At the heart of our company's commitment to excellence, the LYC-J Series Coalescence Dehydrated Oil Filter stands as a leading innovation in the field of dehydrated oil filtration. The successful use, effective after-sales service, and genuine customer feedback continue to shape the product's narrative and dominance in the marketplace.

Start from its utility. The LYC-J series has revolutionized oil filtration with its dual-function design for filtering impurities and removing water simultaneously. It's a testament to technological advancements, ease of use and efficiency. This product has been engineered keeping customer's needs in mind. It ensures a seamless and convenient dismantling process which makes replacing the filter elements a walk in the park. Hence, it significantly minimizes downtime in any industrial environment.

Our user guidelines further ensure a smooth experience. Each product comes with a dedicated user manual containing detailed steps for installation and usage, ensuring users get the maximum performance out of their filtration systems.The quality of our after-sales service has been appreciated widely. We have an efficiently trained service team that is reliable, responsive and capable of troubleshooting any minor to major issues in real-time. We have streamlined our feedback system where customers can report any issues while our service team dispatches the required solution instantly. Our dedicated customer support promptly handles maintenance requests to keep downtime to a minimum.

More importantly, we take customer feedback seriously. The relationships we have with our customers extend beyond the initial sale, and valuable feedbacks continue to alert us to areas of our products and services that might need improvement. We take pride in our customers who have experienced significant productivity improvements and they vouch for our product's performance and reliabilities. This customer satisfaction is a testament to the quality of our products which inspires us in further innovation and enhancement.