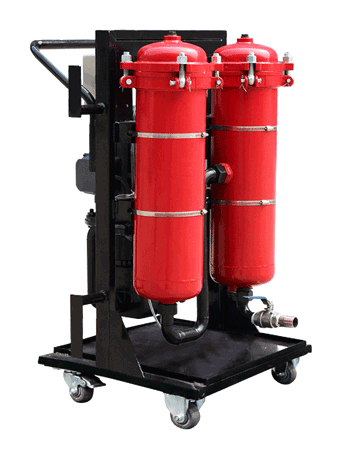

The LYC series high-precision oil filter serves a pivotal role in purifying and separating impurities from various types of oils. Whether for hydraulic oil, transformer oil, or even cooking oil, this high-precision filtration system is effective in ensuring the purity and enhancing the quality of oil.

The primary purpose of the LYC series high-precision oil filter is to remove unwanted particles, thereby improving the longevity of machinery reliant on oil for operation. This process aids the overall efficiency and reliability of several systems, from manufacturing mechanisms to cooking appliances and more.

The core functionality of the LYC series, at its most basic, is to sieve through oils and filter out particles below specific size thresholds. Depending on the demands from different industries, these oil filters can detect and capture particles as small as 1 Micron.

Most commonly, the LYC series finds its applications in industries that work with hydraulic lubrication systems, like manufacturing, power plants, automotive and aerospace sectors. It contributes significantly to maintaining the oil's cleanliness, the prevention of machine damage and the enhancement of operational efficiency.

Prominent features of the LYC series high-precision oil filter include not only its high filtration accuracy but also its wide applicability, robust design catering to tough conditions, and easy maintenance.

These unique advantages prove vital in various contexts, where maintaining the highest level of oil cleanliness can prevent costly machinery damage, enhance reliability, and improve operational efficiency. Because of these benefits, LYC series stands as a preferred choice for high-precision oil filtration across multiple industries.

Absolutely. With its unique balance of durability, reliability, and versatility, the LYC series high-precision oil filter holds supreme positioning in the oil purification industry. Let's discuss its specific advantages in more detail:

High Filtering Precision: The main strength of the LYC series oil filter lies in its extraordinary precision. With the capacity to filter out particles as tiny as 1 micron, it ensures the removal of both macro and micro impurities from the oil. This level of accuracy not only enhances oil purity but also contributes significantly towards the operational efficiency of machinery and systems which rely on oil. The increased life of oil further saves considerable costs related to oil changes and maintenance.

Broad Oil Compatibility: The LYC series demonstrates remarkable versatility as it is engineered to purify a wide range of oils. From hydraulic oil, coolant oil to insulating oil and more, this oil filter stands versatile and ready. This feature makes it a valuable asset for multiple industries—right from manufacturing to power plants, and from the automotive sector to the aerospace industry.

Excellent Reliability and Longevity: Aside from its high precision and versatility, the LYC series oil filter is known for its robust and durable design. Created for long-term use, it brings resilience to withstand challenging operating conditions while maintaining its high performance. Its steadily-built housing and core components are resistant to wear and tear, promoting a longer lifespan than many other filters. This reliability reduces frequent replacements and thereby saves costs in the long run.

In summary, the LYC high-precision oil filter packs impressive features and capabilities - featuring high filtration accuracy, a broad range of oil compatibility, and excellent longevity. All these qualities make the LYC series oil filter an industry favorite, fulfilling their varied demands while ensuring optimal system performance and cost-effectiveness.

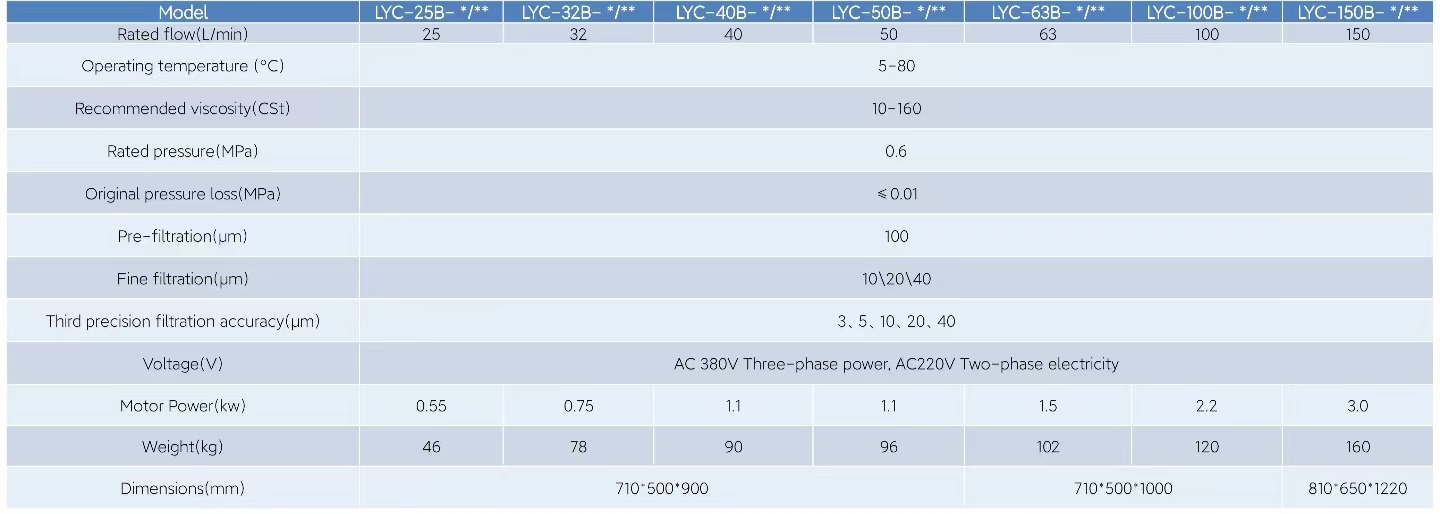

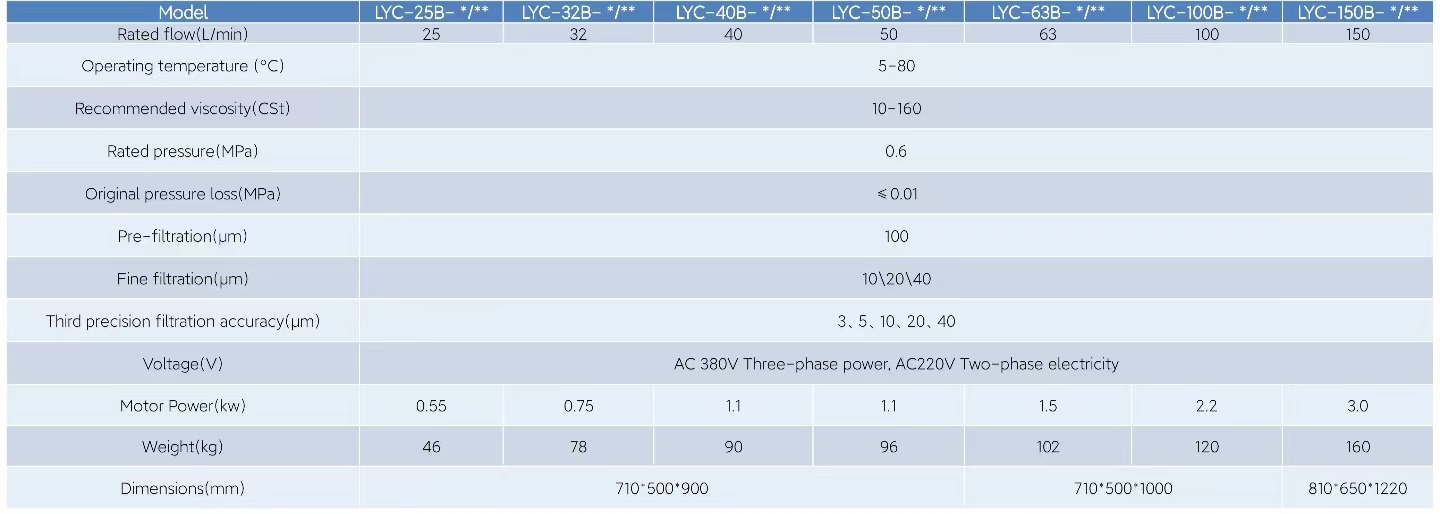

The technical specifications of the LYC series high-precision oil filter

Filtering Accuracy: The LYC series high-precision oil filter boasts a first coase filtration accuracy of 100μm and secondary precision filtration ranging from 10-40μm to as low as 3μm depending on model and configuration. This precise filtration ability ensures that impurities of varying sizes are effectively captured and removed.

Operating Pressure: The rated pressure for this oil filter series is approximately 0.6 MPa. This reflects the maximum working pressure that the filter can handle without experiencing functional problems or failures.

Operational Temperature Range: Specific operational temperature ranges depend on factors like model and usage conditions. However, most oil filters are designed to withstand wide temperature variations, ensuring effective performance in diverse working environments.

Dimensions: The size of the oil filter can differ based on specific models. For instance, the LYC-32B model measures 710mm x 500mm x 900mm. The compact size makes this oil filter easy to install in various spaces.

Weight: Similar to dimensions, the weight also varies depending on the model. The LYC-32B model weighs approximately 78kg. This relative light weight contributes to the ease of installation and mobility of the unit.

Please note that the specific technical specifications might show slight variations based on the exact model of the LYC series high-precision oil filter used.

This oil filter series is recognized for its top-notch performance and unyielding mechanism, which makes it sturdy enough for repeated use. Its high compatibility with different oils and its advanced filtration accuracy contribute to the overall value that it provides, managing to stand as a reliable asset for any industry.

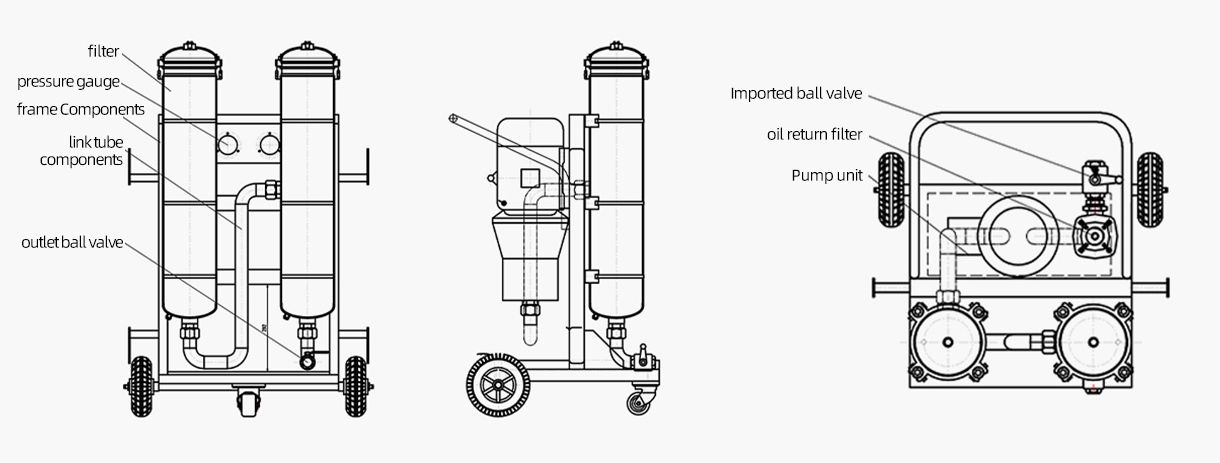

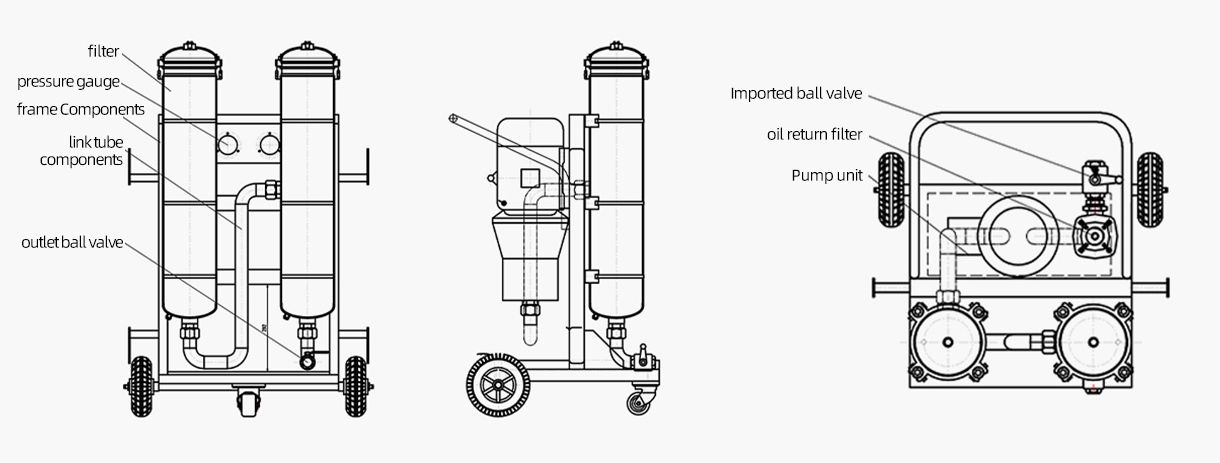

The LYC series high-precision oil filter operates on a sophisticated and innovative mechanism that ensures the comprehensive purification of oil. Here's a step-by-step breakdown of how this oil filter works:

Initial Filtration: The oil first encounters a coarser outlying filter which is designed to capture larger impurities. This preliminary filtration ensures that the bulk of the solid pollutants are removed early in the process to prevent damage to more delicate components.

Pump Circulation: This filtered oil is then circulated by a pump that pushes it further into the system. This pump is carefully engineered to offer strong self-priming ability and stable operation, reducing the risk of cavitation and the accompanying damage.

Precision Filtration: In this refining stage, the oil goes through a high-precision filter. Here, minute impurities as small as 1 to 40 microns according to model and configuration, are removed. This secondary precise filtration enhances the purity of the oil by removing both macro and micro contaminants.

Flow Regulation: This filter includes a flow control valve to regulate the amount of oil that is dispensed from it. This is crucial in maintaining a consistent flow rate which promotes steady operation and prevents sudden pressure spikes that could damage the system.

Final Output: Ultimately, what emerges from the LYC series high-precision oil filter is clean, high-quality oil. The removal of impurities protects engine components from unwanted wear and tear, ensuring longer component life and improving system performance.

In summary, starting from capturing larger impurities in the primary stage to eliminating minute pollutants in the precision stage, the LYC series high-precision oil filter ensures thorough filtering. All of this is done to ensure that the oil circulated is free from contaminants and can perform optimally in various forms of machinery.

The LYC Series High-Precision Oil Filter is an exemplary device in its class and offers several impressive features:

Variable Filtration Precision: With precision filtration accuracies ranging from 3, 5, 10, 20, to 40 micrometers, it caters to varied needs. This variability ensures that it can be effectively deployed in a myriad of industrial scenarios requiring different filtration demands.

Comprehensive Filtering Process: The LYC series emphasizes a two-stage filtration process. An initial coarse filtration stage, accurate to 100 micrometers, catches larger particles and heavy contaminants. The secondary precision filtration stage refines the oil, capturing smaller impurities. This dual-phase process ensures exceptional filtration performance.

Robust Design: One notable feature is its robust construction. Made of high-quality materials and components, it provides long-lasting, reliable service. It is designed to tolerate harsh operating conditions typical in the industrial environment.

Superior Operational Performance: The LYC series high-precision oil filter boasts an efficient pump designed for strong self-priming capabilities, reducing the possibility of cavitation and facilitating stable performance.

Flow Control: A unique feature within this oil filter is the integration of a flow control valve, an essential function that maintains a consistent flow rate of the filtered oil. This not only enhances operational efficiency but also sustains the service life of machinery where the oil is utilized.

High Particle Retention: Owing to the meticulous engineering behind the filtration elements, this filter is able to retain a significant amount of impurities both in the coarse and precision filter. This high particle retention ensures that the oil output is of optimal purity.

In summary, the LYC series high-precision oil filter offers a robust, effective, and efficient solution for oil purification needs with a high degree of filtration precision. Its unique design and operational features prove incredibly beneficial for a wide range of industrial applications.

The LYC series high-precision oil filter finds application across numerous sectors, including but not limited to:

Manufacturing Industry: Given its superior precision filtration, it's commonly used in the manufacturing sector where machinery often requires clean, refined oil.

Automotive Industry: Vehicles, especially those involving heavy-duty operations, rely on high purity oil for optimal engine performance.

Power Plants: In electricity generation units, where turbines and generators require high-quality lubrication, the LYC series oil filters prove crucial.

Oil Refineries, Petrochemical Plants: These sectors necessitate a high level of refined oil, making this filter an indispensable choice.

As for machinery types, the filter finds use in hydraulic systems, lubrication systems, mechanical transmission systems, oil cooling systems and more, where unprocessed oil can lead to the rapid degradation of components.

Implementing the LYC series high-precision oil filter within these sectors significantly enhances performance and extends the lifespan of products in several ways:

Impurity Removal: By eliminating tiny particles and contaminants, the oil filter ensures that mechanical components are exposed to less wear and tear, thereby enhancing the overall performance and lifespan of the machinery.

Ensuring Consistent Oil Quality: The oil filter maintains high oil purity consistently, which optimizes equipment functionality and improves efficiency.

Preventing Engine Damage: With the filter's ability to seize even the minutest of impurities, the chances of engine damage, jamming or oilway blockage are drastically reduced, enabling smoother, longer operation.

Reducing Maintenance Cost: The application of this oil filter minimizes the frequency of oil changes and equipment maintenance, effectively reducing operation costs and extending the lifespan of machinery.

Environmental Conservation: By prolonging the lifespan of oil, the LYC series high-precision oil filter indirectly contributes to less waste and better resource conservation.

To summarize, the LYC series high-precision oil filter offers superior filtration performance, enhancing machinery operation and extending the lifespan of components across various sectors and machinery types. This not only improves performance and reliability but also cuts down on maintenance and operation costs, making it an invaluable asset in industrial applications.

Certainly, proper installation and maintenance are key to maximizing the longevity, performance, and safety of the LYC series high-precision oil filter. Here are some guidelines and tips:

INSTALLATION:

Ensure compatibility: Before installing the oil filter, verify that it's compatible with your machinery or engine.

Cleanliness is paramount: Make sure the location for installation is clean to prevent contamination of the filter.

Direction matters: The oil filter should be installed in the direction of oil flow. There should be clear labels indicating the correct installation direction.

MAINTENANCE TIPS:

Regular Inspections: Frequent checks are essential to ensure the equipment's optimal operation. Look out for any leaks, abnormal noises, or pressure changes.

Do not Overuse: Always follow the manufacturer's guidelines for filter replacement. Prolonged use beyond the advised limit can result in diminished filtration efficiency, damage to the equipment, or even system failure.

Keep a Record: Documenting the filter changes and noting any abnormalities can be helpful in spotting trends or recurrent issues.

TO MAXIMIZE LONGEVITY & PERFORMANCE:

Timely Replacement: Replace the filter timely to prevent clogging, which can hinder filtration performance and damage the equipment.

Keep it clean: External cleanliness of the filter just as important as interior cleanliness. So, Deterioration of the filter’s exterior can lead to internal contamination.

Always Use Genuine Parts: Non-genuine parts might impair performance and may even damage the equipment and void warranty.

ENSURING SAFE OPERATION:

Appropriate Handling: The filter should be handled, installed, and removed with care to prevent any harm or damage caused by improper handling.

Never Bypass The Filter: Running the system without the filter can lead to damage to the equipment and can also be hazardous.

To conclude, the key to maximizing the performance of the LYC series high-precision oil filter lies in proper installation, regular inspections, and scheduled maintenance in adherence with the manufacturer's guidelines.

Certainly, the LYC series high-precision oil filters must have certain features and benefits that discern them from other competitors in the market. Although the specific comparative advantages may vary depending on the competitor, some potential advantages could include:

High Precision: As the name implies, LYC series filters are high-precision filters that provide exceptionally fine filtration precision. This feature enables them to effectively remove micro-level impurities, ensuring oil cleanliness to the maximum extent.

Multi-Stage Filtration: LYC series filters typically comprise multiple stages of filtration. This design enhances filtration effectiveness by ensuring that contaminants of all sizes are effectively eliminated.

Advanced Materials: The use of high-quality, advanced materials helps these filters withstand high temperatures and shock. This aspect extends the lifetime of the filters and ensures consistent performance even under harsh operational conditions.

Versatility: LYC series filters may come in various models, each designed for a specific type of fluid or application. This versatility allows consumers the flexibility to choose a model that fits their specific needs perfectly.

Ease of Maintenance: These filters often feature an easy-to-clean design. Routine maintenance and filter replacement is typically straightforward and hassle-free, minimizing the interruption to your daily operations.

High Absorption: LYC filters are known for their high absorption capacity, which guarantees smooth operation of your machinery by providing a stable and clean oil supply.

Please note that these are potential advantages based on typical high-precision filter features. The actual advantages of LYC series filters can vary depending on the specific model and are best established through practical application and professional testing.