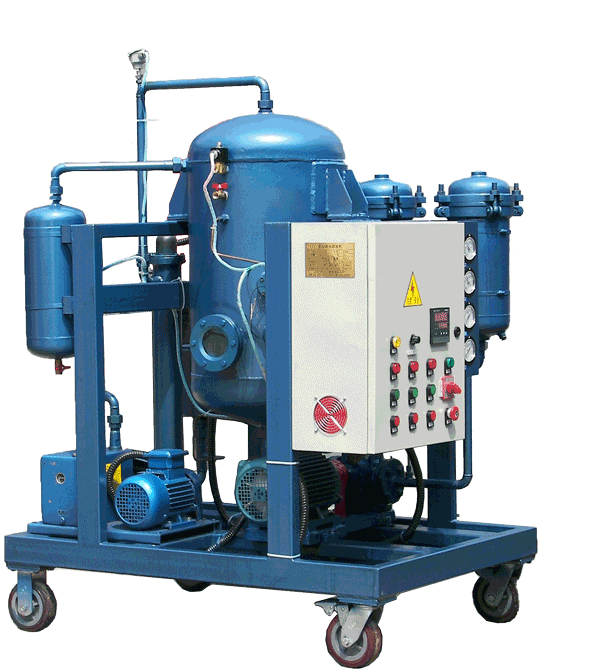

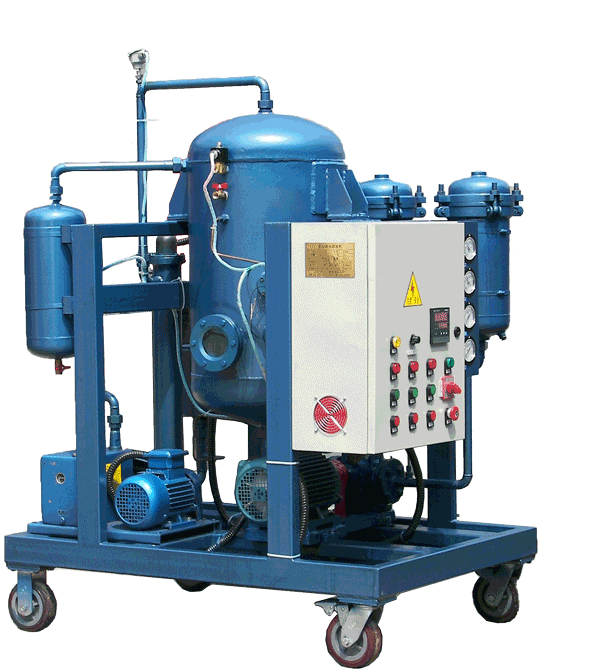

Product Description

The vacuum oil filter is designed according to the different boiling points of water and oil. It consists of a vacuum heating tank fine filter, a condenser, a prefilter, a water tank, an empty pump and an oil drain pump and an electrical cabinet. The empty pump draws out the air in the vacuum tank to form a vacuum. Under the action of atmospheric pressure, the external oil enters the primary filter through the inlet pipe to remove larger particles, and then enters the heating tank. After heating, the oil of 40~75C passes through. Automatic oil float valve, this valve is to automatically control the balance of oil in and out of the vacuum tank. The heated oil is separated into a semi-mist by the rapid rotation of the jet wing, and the water in the oil is rapidly evaporated into water vapor and continuously sucked into the condenser by the vacuum pump. The water vapor entering the condenser is cooled and then returned to the original water and released. The oil in the vacuum heating tank is discharged into the fine filter by the oil discharge pump to filter out the particulate impurities through the oil filter paper or filter element, so as to complete the vacuum oil filter quickly. The whole process of removing impurities, moisture and gas in the oil makes the clean oil drain out of the machine from the oil outlet.

Product Advantages

The ZLYC High-Efficiency Vacuum Oil Filter Machine provides numerous significant advantages that make it an effective solution for oil filtration:

Innovative Design: This vacuum oil filter machine features an optimized structure design. It increases significantly the oil's surface area in the overall vacuum system and maximizes the journey of oil within the vacuum system itself. This leads to efficient water and gas removal from the oil.

High Filtration System: The machine adopts an efficient three-filter system. The first coarse filter at the inlet protects the pump and extends the life of the main filter. Consequently, the filtration system effectively filters out impurities while significantly improving the lifespan and efficiency of the machine.

Efficient Heating System: The ZLYC High-Efficiency Vacuum Oil Filter integrates a segmentation heating system that ensures the uniform heating of oil. It results in stable oil temperature and greatly enhances overall filtration performance.

Impurities Removal Technology: This machine includes state-of-the-art impurities removal technology that features double FH trapezoidal network and absorption by high polymer, without relying on mechanical power. This mechanism not only has high efficiency but also contributes to saving energy.

Versatility: This vacuum oil filter machine is versatile enough to treat various oils. It ensures that the treated hydraulic lubricating oil consists of low emulsification value, few water content, and few impurities. Thus, it makes the oil suitable for repeated use in other applications.

High-efficiency Purification: The ZLYC High-Efficiency Vacuum Oil Filter Machine expedites the oil purification process. The high-power filtration technology it employs ensures high-speed deep cleaning. It effectively removes particles, water, and other impurities from the oil, increasing the performance of your oil-related machinery.

In a nutshell, the essential advantage of the ZLYC High-Efficiency Vacuum Oil Filter Machine stems from its high-efficiency purification, innovative design, efficient filtration and heating system, advanced impurities removal technology, and versatile oil treatment. With these features, it ensures the provision of purified oil suitable for various applications, making it an invaluable tool in many industry sectors.

Equipment performance

1. Vacuum system: It consists of vacuum tank, vacuum pump, condensation tank, liquid accumulation tank and air supply system. The optimized structure design greatly increases the surface area of the oil in the vacuum system, and maximizes the travel of the oil in the vacuum system, so that the moisture and gas in the oil can be fully overflowed. This machine adopts an advanced defoaming system, so that the oil purifier will never appear the phenomenon of oil injection commonly seen in similar products when it is working.

2. Filtration system: Three-stage filtration is adopted, and the oil suction port coarse filter protects the oil pump and prolongs the service life of the main filter. There are two-stage fine filter behind the pump, so that the oil can quickly reach a high degree of cleanliness. The filter material is made of special graded pore glass fiber material, which can filter particles of different particle sizes in layers, which greatly improves the service life of the filter element. It has a perfect filter element structure, which can effectively reduce the surface flow rate of the filter material and obtain stable filtration accuracy.

3. Heating system: It adopts stage-by-stage heating, the surface heat load is less than 1.OW/cm2, and the oil will not be deteriorated due to overheating. The oil temperature can be adjusted arbitrarily from 0 to 100°C, automatically controlled, and equipped with a protection device. When the oil intake is too small, it will automatically stop working to avoid damage to the heater caused by dry burning.

4. Automatic control system: This machine adopts a series of automatic control instruments such as frequency converter, liquid level transmitter, temperature sensor, and vacuum sensor to collect various information about the operation of the equipment, and hand it over to the central processor for processing. Automatically control the operation of the entire equipment and monitor the operation status of the equipment. The machine is equipped with various protection devices (overload protection, overvoltage protection, phase sequence protection, abnormal operation shutdown protection), which can ensure the safe operation of the equipment.

5. Whole machine structure: The whole machine-integrated bridge structure reduces the volume. The overall removable oil tank is used to ensure oil-free operation on the ground and reduce environmental pollution. There are mobile, fixed, fully enclosed, vehicle-mounted and other models to choose from.

Working Principle

The ZLYC High-Efficiency Vacuum Oil Filter Machine primarily works on the principles of vacuum filtration and adsorption technology. It operates via a series of interconnected steps which include:

Pumping and Coarse Filtration: Initially, the oil to be purified is pumped from the tank into the oil filter. The machine is equipped with a protective pump at its inlet and a primary coarse filter that initially filters large particles. This is essential to protect the machine from clogging and prolong the life of the main filter elements, ensuring efficient operation.

Heating: The oil then passes through a segmented heating system which reduces the surface velocity of the filter. The heating system features segmented heating zones which ensure thorough and uniform heating of the oil. This process helps the oil to reach an optimal temperature for efficient filtration and the extraction of impurities.

Vacuum Filtration: Post-heating, the oil enters the vacuum system. The machine's innovative structure design amplifies the surface area of the oil in the vacuum, leading to increased oil travel. This process facilitates an efficient removal of water, gas, and other elements from the oil.

Fine Filtration: After the vacuum filtration, the oil is pushed through two fine filters which ensure the oil reaches high degrees of purity. The filter elements are known for their high efficiency and precision, capable of filtering microscopic impurities to deliver near-perfect filtered oil.

Defoaming: Simultaneously, the machine also integrates an advanced defoaming system that prevents foaming of the oil during the filtration process. This ensures that the machine can carry out its operation without having to deal with similar issues typically associated with other filtration units.

Adsorption: In tandem with the vacuum filtration, the machine also employs adsorption technology. It utilizes high polymer material for the absorption of impurities, leading to deep and thorough purification of the oil.

The working mechanism of ZLYC High-Efficiency Vacuum Oil Filter Machine makes it an ideal and efficient solution for oil filtration, maintaining high purification standards for various applications and environments.

Applications

The ZLYC High-Efficiency Vacuum Oil Filter Machine finds its applications in several industries due to its high operational efficiency. These are as follows:

Power Generation Industry and Electric Appliance Factories: The machine is used for cleaning and filtering transformer and turbine oils, ensuring the smooth functioning of transformers and turbines.

Paper Mills: In the paper-making process, machinery involves a significant amount of lubricating oils and hydraulic oils. This machine can effectively remove impurities and moisture from the oils, enhancing the efficiency and life of the equipment.

Petrochemical Factories: During the petrochemical process, high-quality oils are required. The ZLYC high-efficiency vacuum oil filter machine provides efficient filtering services, greatly improving the quality of the oils.

Industrial and Mining Enterprises: The machinery in these industries requires high-quality lubricating and hydraulic oils. This machine ensures the cleanliness and quality of the oils, guaranteeing the efficient operation of the machinery.

Hydraulic and Lubrication Systems: The machine serves for the purification of turbine oil, transformer oil and for the removal of water and impurities from hydraulic lubrication oil, offering quality oil filtration services.

These varied applications demonstrate the extensive versatility and diversity of the ZLYC High-Efficiency Vacuum Oil Filter Machine, making it an invaluable asset across various industries.

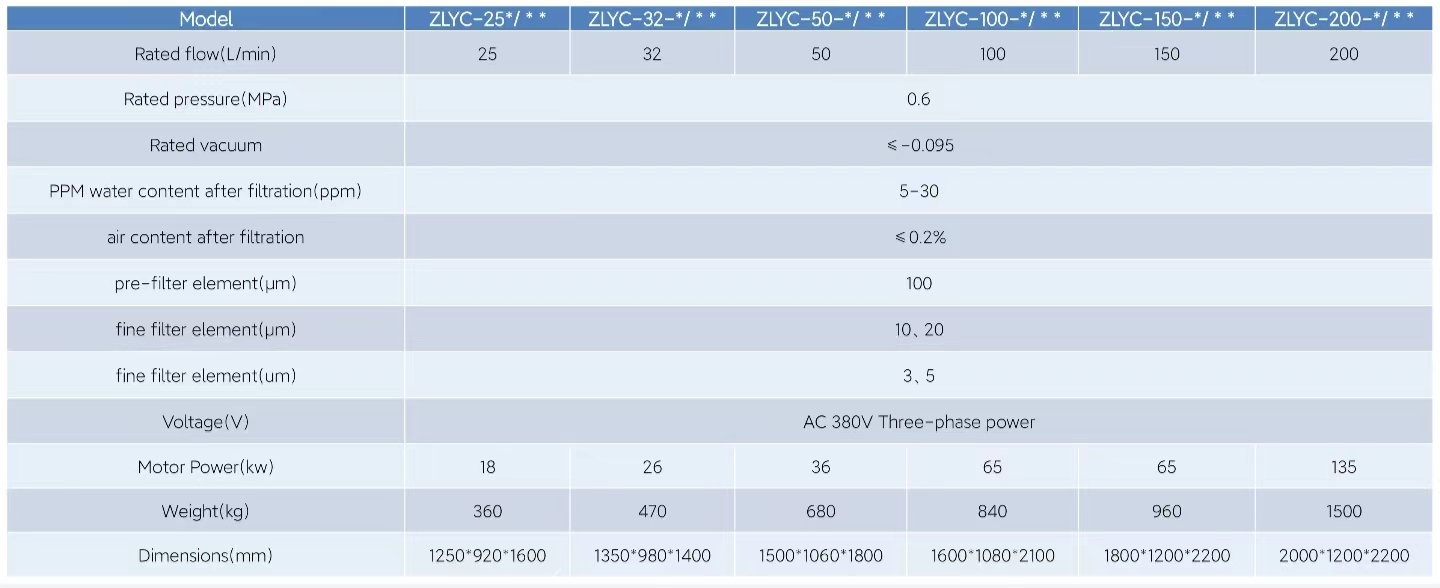

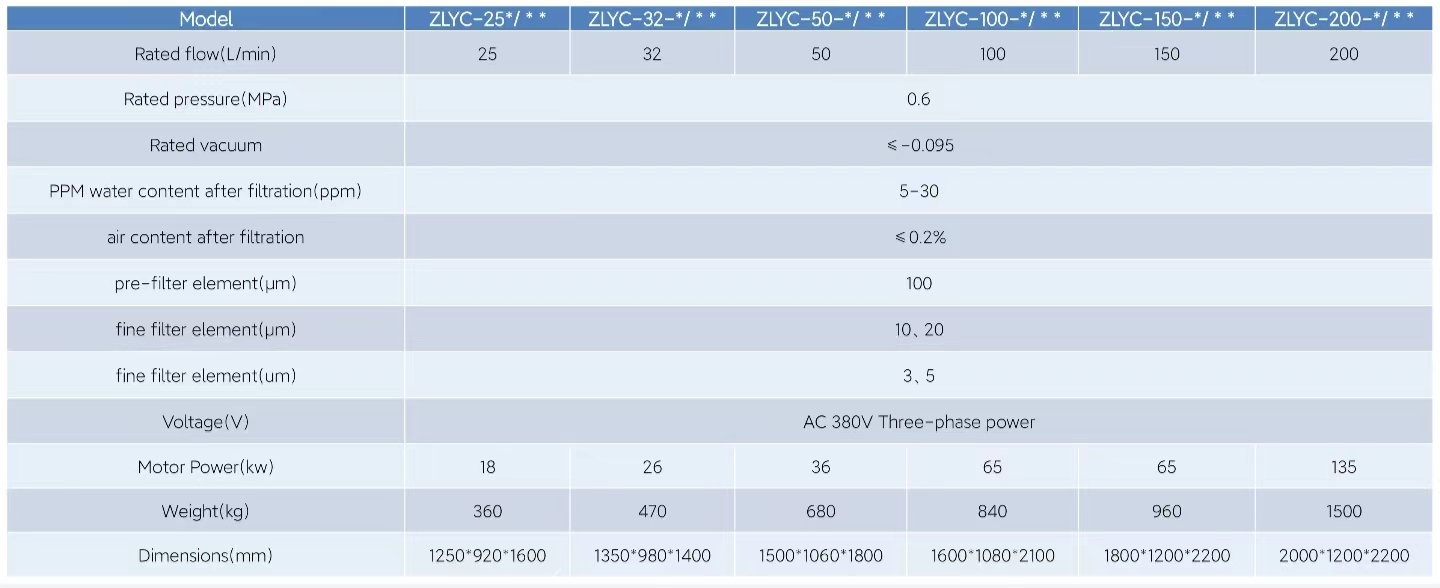

Technical parameters

RELATED PRODUCTS

LYC Portable Filter Purifier

LYC Coalescence Dehydration Oil Filter