Product Description

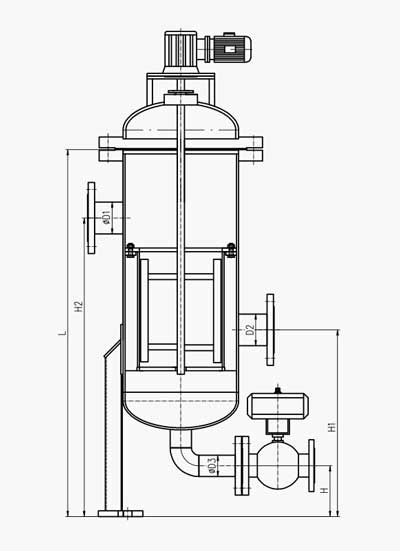

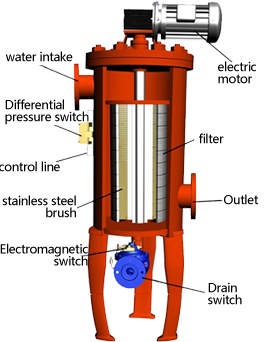

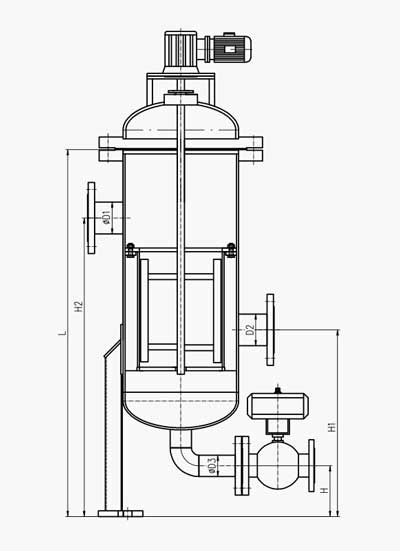

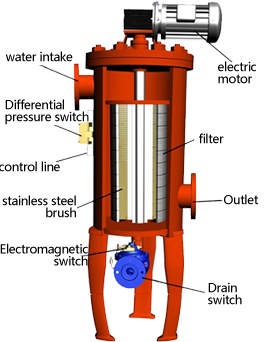

The Brush type self-cleaning filter is a highly precise type of filter, consisting of high-strength filter elements such as stainless steel or wedge nets. Its functionality is extended by a specially designed cleaning device which helps maintain the system during operation without going through a shutdown phase, thereby reducing any maintenance required.

The operation is rather easy, and it can automatically discharge the wastewater through a drain pipe after each cleaning cycle. This makes it especially suitable for continuous operations, and it’s also environmentally friendly due to no emissions involved.

Due to its robust structure and design, it is capable of handling judicially significant loads and conditions. Furthermore, its optional range of filtering accuracy varies from as low as 50 microns to as high as 5000 microns, making it a versatile tool for various industry requirements.

Technical parameters

Use pressure:0.2-2.5Mpa | Tank material: Q253B, 304,316, 316L, carbon steel lined with rubber |

Operating temperature: ≤ 80℃ | Cleaning brush material:304 316L |

Using voltage: 380v 50hz | Cleaning method: brush type |

Backwashing water consumption:≤2% | Cleaning time: 60s or adjustable |

Filtration precision: 50-5000 microns | Control mode: manual, automati |

Filter element material: 304 316L 2205 |

|

Working Principle

The Brush type self-cleaning filter works uniquely in offering consistent and efficient filtration performance without constant need for manual cleaning of the filter elements, thus making it highly user-friendly.

Here is a detailed working principle of this filter:

Inlet of liquid: The filter starts its process when the liquid enters the filter from the inlet, flowing inward through the filter element. The impurities are blocked on the inner surface of the filter element, thus separating and trapping them from the liquid. This filtration process from the inside-to-out approach aptly ensures maximum filtration surface usage and less frequent cleaning cycles as compared to traditional methods.

Monitoring of pressure: The differential pressure across the filter increases due to a gradual build-up of impurities on the filter element's inner surface. A pressure difference transmitter is typically used to monitor the differential pressure, giving an accurate and precise reading.

Initiation of cleaning cycle: Upon reaching a specified level relating to the filter impurity concentration or a preset time interval (whichever is first), the cleaning cycle will be initiated. This automatic function allows for a seamless filtration operation without stopping the main flow of liquid.

Cleaning process: The cleaning process is performed by a motor driven brush which moves along the inner surface of the filter element. The brush effectively and efficiently removes the trapped particles and deposits on the filter element. The collected debris is subsequently guided to the drain chamber located at the bottom of the filter by gravity.

Draining of impurities: Once a sufficient amount of impurities has accumulated in the drain sump, the outlet drain valve gets activated, allowing the impurities to be flushed out from the system. This ensures a successful regeneration of the filtration function and allows for continuous filtration operation.

The amazing part of this self-cleaning filter is that it doesn't interrupt the regular flow of the process liquid during the cleaning cycle. This fact alone proves its efficiency, where other conventional filters would need a shutdown period for filter cleaning.

Lastly, the design of this self-cleaning filter ensures effective cleaning and reduces the volume of discharge water used in the cleaning process, thus lessening the overall environmental footprint. It's an ideal option for wide-ranging industrial applications that require filtration processes.

Product Advantages

The Brush Type Self-Cleaning Filter possesses diverse advantages and unique features that make it an excellent choice for a variety of industrial filtration applications. Here is a detailed list of these features and benefits:

Efficient Self-Cleaning: The filter’s most notable feature is its innovative self-cleaning mechanism. It enables regular and prompt cleaning operations which significantly reduces the accumulation of impurities. The cleaning protocol guarantees the consistency of its filtration efficiency.

Continuous Operation: The filter’s design ensures that the filtration process remains unimpeded during the cleaning cycle. It closely maintains the flow volume and pressure, ensuring a continuous and uninterrupted operation.

Low Maintenance: Automatic self-cleaning filters typically require minimal maintenance. Because they constantly clean themselves, manual cleaning is rarely necessary - reducing time, labor, and cost for operation.

Versatility: Due to its wide range of filter accuracy options (from as low as 50 microns to as high as 5000 microns), it is highly versatile, catering to various industrial requirements. The brush type handles different liquids and types of impurities effectively.

Environmentally Friendly: It's designed to be environmentally friendly, minimizing waste. The cleaning cycle only uses a small volume of drain water, reducing overall consumption. Filter element materials are durable and reusable, minimizing waste.

Rugged and Durable: The filter is often constructed from high-strength materials, such as stainless steel or monel, providing excellent resistance to the mechanical and chemical stresses they might experience in service.

Compact Design: Its design is quite compact for its capacity, allowing for a smaller footprint and weight than many alternative solutions. This makes it an excellent option for applications where available space is at a premium.

Return On Investment: Whilst the initial cost may be higher than conventional filters, the long-term cost savings that come from reduced maintenance, reduced downtime, and increased efficiency effectively give a good return on investment.

Applications

※Large filtration area

※ high pollution capacity,

※high cycle monitoring

※Strong maintainability, easy to install and disassemble

※Equipped with motor overload protection

※Short cleaning time and low water consumption for sewage discharge

Order Information:

RELATED PRODUCTS

Multi-column self-cleaning filter

Sucking self-cleaning filter