Our customers

The softened water equipment needs to be designed according to the actual situation on site. Lefilter provides a full set of on-site measurement, scheme design, installation and commissioning and after-sales service.

------Equipment selection: softened water equipment

The machining industry plays a fundamental role in the national industry, and it is also a pillar industry of a country, which can greatly affect the development of the national economy. In recent years, the global machining and manufacturing technology

has developed rapidly, and the production efficiency and technical precision have been continuously improved. At this stage, the pollution of mechanical processing is also very serious. It is necessary to strengthen the supervision

and management of the oily wastewater and other toxic and harmful wastewater treatment work by enterprises, and strictly prevent the excessive discharge of toxic and harmful wastewater in the production process, which endangers human

health and pollutes the surrounding environment.

t present, the pollution of mechanical addition T is mainly caused by the pollution of various residual liquids in the dry manufacturing process. In the process

of machinery manufacturing, the wastes generated by lubricating oil, cutting fluid, polyurethane, cleaning fluid, cooling fluid, etc. are not thoroughly treated, and are directly discharged to the ground, polluting the groundwater.

In the mechanical processing industry, the more common wastewaters are: painting wastewater, dust removal wastewater, Fu, chemical liquid preparation wastewater, etc. The main methods of waste water generation are partial discharge

of circulating water and all discharge and renewal of circulating water after long-term use. Wastewater pollutants are mainly divided into two categories: domestic sewage and production wastewater. Domestic waste water mainly includes

waste water from Hetang Hall, accommodation waste water and domestic office waste water; production waste water in the machining industry mainly includes painting waste water, dust removal waste water, emulsion preparation waste water

and so on. In order to save trouble, some factories directly discharge these waste water, and then seriously pollute the groundwater.

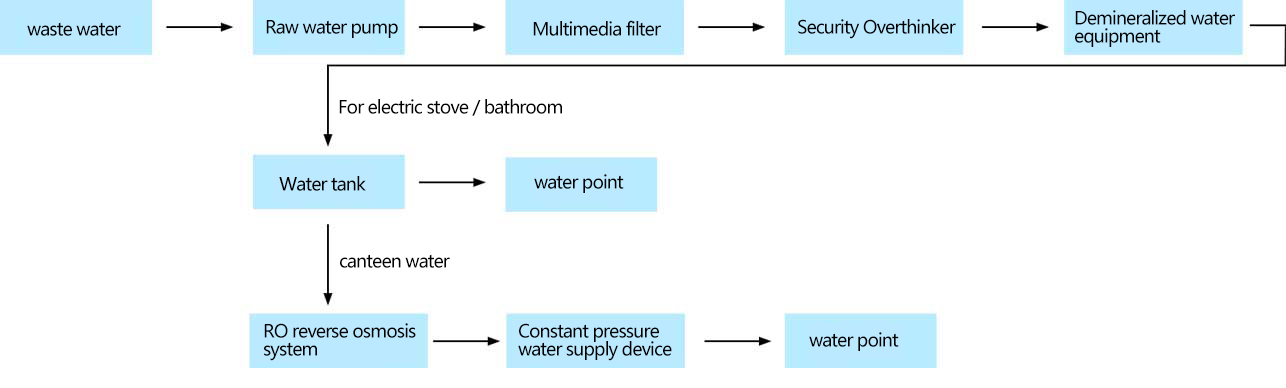

The waste liquid and washing wastewater discharged from machining various metal products mainly contain various metal ions, which are highly toxic. Wastewater involves a wide range and is highly polluting, and is one of the key industrial wastewaters to be controlled. Therefore, the multi-media and reverse osmosis equipment solutions are equipment units recommended for purifying water quality based on the water quality and other relevant conditions provided by various polluting enterprises, taking into account the concepts of water saving, environmental protection, and low energy consumption.

The waste water is discharged from the cleaning line and collected into the regulating tank, which mainly regulates the water quality and quantity. The effluent of the regulating tank is lifted by the pump and enters the reaction tank. Since there are many metal ions in the wastewater (if the metal ions are insufficient, they can be supplemented), sodium hydroxide is added into the reaction tank, and the agitator is used to stir and mix, so that the metal ions and the hydroxide radicals are mixed. The ionic reaction produces a metal hydroxide precipitate that is insoluble in water. The pump is lifted into the multi-media filter reverse osmosis equipment for processing.

Overview:The softening water equipment is composed of automatic softening water controller, salt box, strong acid type sodium ion cation resin, resin tank and water softener accessories. Through the control of water flow and time, commands are sent to solenoid valves or multi-channel servo valves to complete the water supply and regeneration of softened water equipment. The most widely used hard water softening treatment equipment in boilers and other occasions.

Application:steam boiler, hot water boiler, heat exchanger, condenser, central air conditioner, direct combustion engine, domestic water, industrial water and other systems.

The softened water equipment needs to be designed according to the actual situation on site. Lefilter provides a full set of on-site measurement, scheme design, installation and commissioning and after-sales service.