CUSTOMIZATION SERVICE PROCESS

Provide customization services according to different working conditions

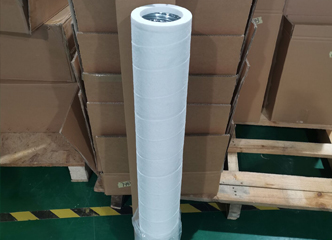

During the transportation of gas pipeline, gas source impurities and pipeline mechanical impurities will affect the gas transmission quality and damage some metering and pressure regulating equipment on the pipeline. Therefore, gas filtering equipment shall be installed in front of each receiving and dispatching station or important equipment to ensure the safety of downstream equipment (sometimes it may go through multi-stage filtering). Filter element is also the main component of these filter equipment, so the selection of filter element directly affects the filtering effect. According to the unique properties of gas, stainless steel metal mesh is selected as the main filter material, and the filter area of the filter element is increased through the wave breaking structure, so as to ensure the good circulation of gas and increase the amount of pollutants. High and low temperature resistant asbestos gasket is used as sealing material to ensure good sealing of some low-temperature gases, such as compressed liquefied petroleum gas. The filter element shall be cleaned or replaced in time according to the change of differential pressure during use.

Large filter area; High precision, large filtering area, large flow, small equipment diameter and small footprint.

High filtration precision:

Relative filtration precision, retention rate is more than 90%, wide range of filtration precision can meet various application requirements, good pollution interception effect and longer service life.

Internal thread structure; Enhanced compression resistance;

Internal thread structure for enhanced compression resistance:

Wide chemical compatibility, large flux, low differential pressure, Can be washed and regenerated, economical.

Made of multi-layer sintering

Material:

Material: multi-layer sintering

Structure

Structure:

Sparse outside and dense inside, honeycomb structure, large dirt holding capacity.

Name: natural gas filter element Maximum operating temperature: 115℃

Sealing torque: 6.9~ 13.8 N-M Filter element precision: 1,5,10 (SCW = 0.3)

Filter element replacement pressure drop: 0.08 - 0.1MPa (not more than 0.17 MPa)

Customized according to different working conditions

Pictures

Video

Application: security filter elementFlow:20t/h

Application: Circulating water treatmentFlow:20t/h

Uses: security filter circulating water treatmentFlow:200m3/h

Provide customization services according to different working conditions

Professional installation team to ensure the normal operation of the equipment

Technical Support