CUSTOMIZATION SERVICE PROCESS

Provide customization services according to different working conditions

Performance and Characteristics

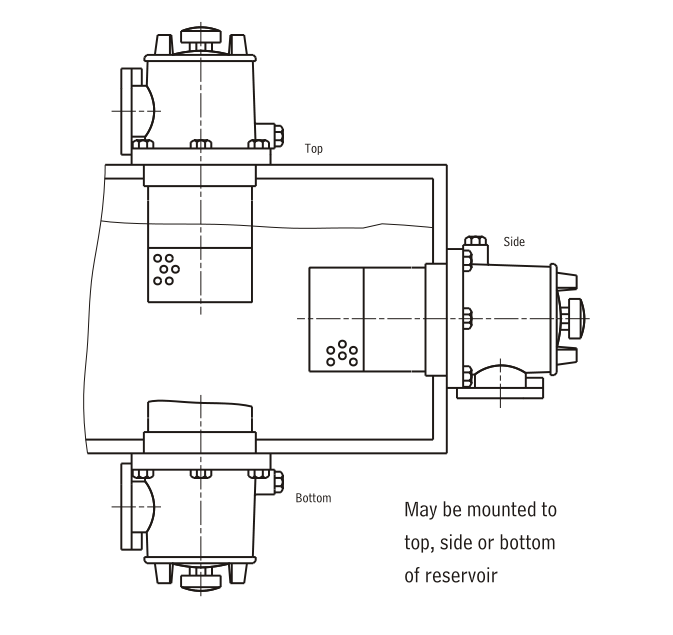

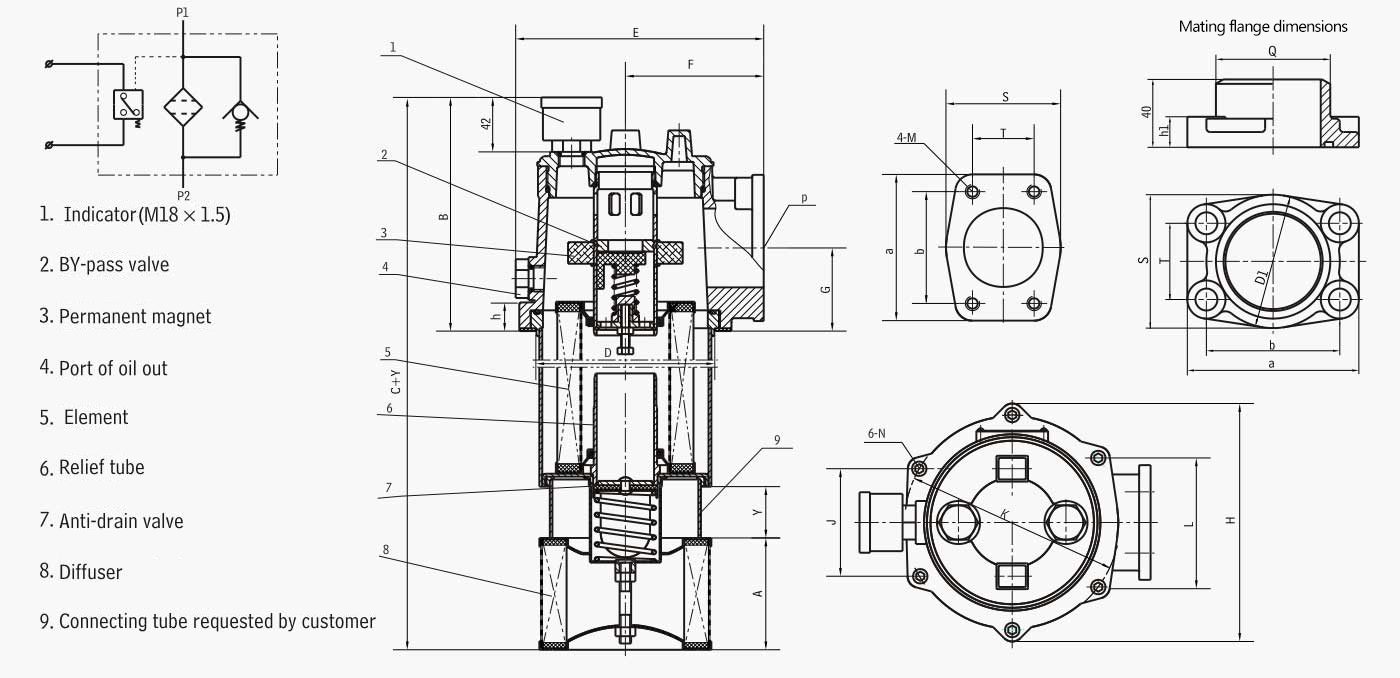

1.The filter can be directly installed on the top,side or bottom of the tank,the filter head is exposed outside the tank,and the cylinder is immersed in the tank,thus simplifying the system pipeline and making the system arrangement more compact.

2.The filter is equipped with permanent magnet,which can filter out ferromagnetic particles of more than 1 micron in oil.

3.With by-pass valve:When the filter element is blocked by pollutants or the pressure difference of the filter is too large due to low system liquid temperature,flow pulsation and other factors, and the host cannot work,the by-pass valve in parallel at the lower part of the filter cover will open automatically (the opening pressure difference is 0.4MPa) to protect the normal operation of the filter element and the system.

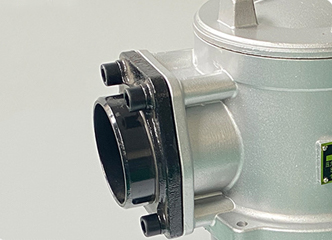

4.Equipped with check valve:the filter is installed on the side and bottom of the tank,when replacing the filter element,the oil in the tank will not flow out.

5.Equipped with liquid flow diffuser:the liquid flow diffuser located at the lower part of the cylinder can make the return oil flow smoothly into the oil tank,which is not easy to produce bubbles,reduce the re-entry air,reduce the disturbance of deposited pollutants,and play the role of coarse filtration when the by-pass valve is opened.

6.With visual indication and electric transmission in one transmission device,overflow pipe and fouling cup:when the filter element is gradually blocked,the blockage of the filter element can be observed on the visual table,and the electric transmission can be received at the same time (the transmission value is 0.35Mpa).The overflow pipe and fouling cup are set at the bottom of the filter element,which can be taken out together when replacing the filter element,so as to avoid the phenomenon of pollutants falling into the oil tank again.

7.The filter element is made of chemical fiber,which has the advantages of high filtration accuracy,large oil passing capacity, small original pressure loss,high pollutant carrying capacity and so on.The filtration accuracy is calibrated by absolute filtration accuracy,the filtration ratioβ3,5,20≥200,in line with ISO standards.

8.The filter element is made of chemical fiber,which has the advantages of high filtration accuracy,large oil passing capacity, small original pressure loss,high pollutant carrying capacity and so on.The filtration accuracy is calibrated by absolute filtration accuracy,the filtration ratioβ3,5,20≥200,in line with ISO standards.

9.With attached oil return holes:two small oil return holes are set on the side and top of the filter head,which can be used to return a small amount of oil in the system to the oil tank for filtration or add a small amount of oil to the oil tank.When the filter is installed on the side or bottom of the oil tank,unscrew the small hole cover to remove the oil containing polluting impurities in the filter,so as to prolong the service life of the filter element and facilitate the purification of oil.

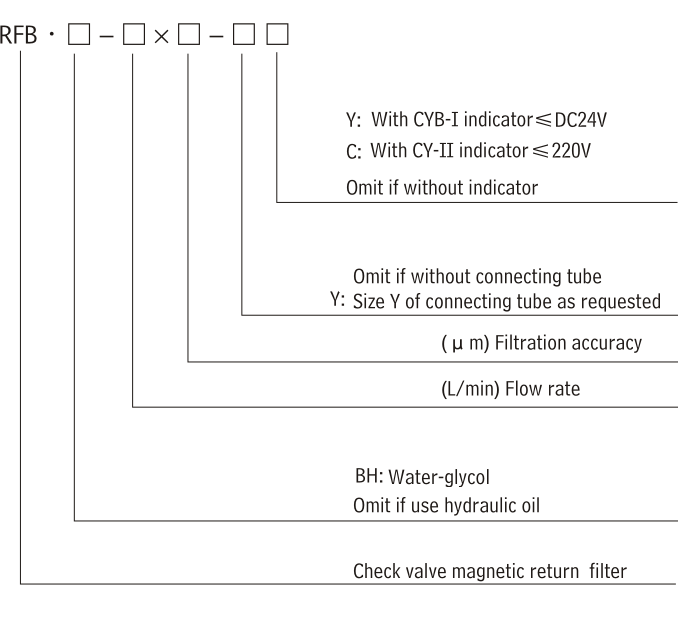

Installation diagram and model description

Technical Parameters

| model | nominal flow rate (L/min) |

filtration accuracy (μm) |

nominal pressure (MPa) |

pressure loss (MPa) |

transmitting device (V/W) |

weight (Kg) |

filter element model | ||

|---|---|---|---|---|---|---|---|---|---|

| Initial | Max. | (V) | (A) | ||||||

| RFB-25 x *C/Y | 25 | 1 3 5 10 20 30 |

1.6 | ≤0.075 | 0.35 | 12 24 63 220 |

2.5 2 1.5 0.25 |

4.6 | FBX-25 x * |

| RFB-40 x *C/Y | 40 | 4.8 | FBX-40 x * | ||||||

| RFB-63 x *C/Y | 63 | 5.3 | FBX - 63 x * | ||||||

| RFB-100 x *C/Y | 100 | 6 | FBX-100 x * | ||||||

| RFB-160 X *C/Y | 160 | 6.7 | RFB-160 X *C | ||||||

| RFB-250 X *C/Y | 250 | 12.3 | FBX-250 X * | ||||||

| RFB-400 x *C/Y | 400 | 14.7 | FBX-400 x * | ||||||

| RFB-630 x *C/Y | 630 | 17.3 | FBX-630 x * | ||||||

| RFB - 800 x *C/Y | 800 | 18.6 | FBX-800 x * | ||||||

| RFB- 1000x*C/Y | 1000 | 21.3 | FBX-1000 X * | ||||||

| RFB- 1300x*C/Y | 1300 | RFB-1300x*C | |||||||

Note:*refers to filtration accuracy.If the medium is water-glycol,nominal flow rate is 63L/min,filtration accuracy is 10μm,with CYB- I transmitter,the filter model is RFB.BH-160x 10Y,and the filter element model isFBX.BH-160X10.

Connection Size

| Model | Size (mm) | |||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | F | G | H | J | K | L | N | P | M | a | b | S | T | Q | h | |

| RFB - 25 x *C/Y | 78 | 167 | 348 | Φ124 | 175 | 96.5 | 58 | 168 | 75 | Φ150 | 90 | Φ7 | Φ55 | M10 | 102 | 78 | 80 | 43 | 60 | 20 |

| RFB - 40 x *C/Y | 374 | |||||||||||||||||||

| RFB - 63 x *C/Y | 411 | |||||||||||||||||||

| RFB - 63 x *C/Y | 473 | |||||||||||||||||||

| RFB - 160 x *C | 548 | |||||||||||||||||||

| RFB - 250 x *C/Y | 120 | 210 | 558 | Φ186 | 250 | 132 | 74 | 245 | 112 | Φ225 | 132 | Φ9 | Φ80 | M12 | 140 | 106 | 110 | 62 | 90 | 22 |

| RFB - 400 x *C/Y | 708 | |||||||||||||||||||

| RFB - 630 x *C/Y | 877 | |||||||||||||||||||

| RFB - 800 x *C/Y | 948 | |||||||||||||||||||

| RFB- 1000 x*C/Y | 1114 | |||||||||||||||||||

| RFB- 1300 x*C/Y | 1454 | |||||||||||||||||||

Note: the connecting flange of the oil inlet is provided by our company.Users only needs to prepare the q-size pipe for welding.

Production Field

product

video

Case Site

function:hydraulic oil filtrationrate of flow:1000t/h

function:hydraulic oil filtrationrate of flow:200t/h

function: oil filtratiionrate of flow:100t/h

Provide customization services according to different working conditions

Professional installation team to ensure the normal operation of the equipment

Technical Support