Welcome to the lefilter website

Oil Purification products

Air Compressor & Inline Filter

Precision Filter element

Air Filter

Hydraulic Filter Housing

Hydraulic Part

Oil Filter Machine

Filter Element

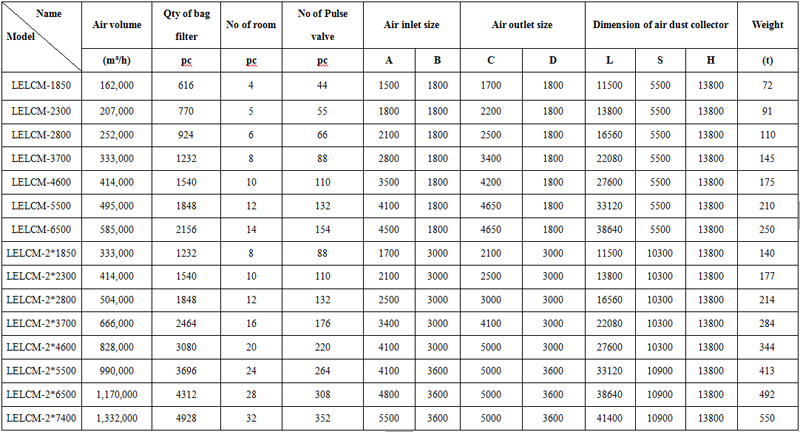

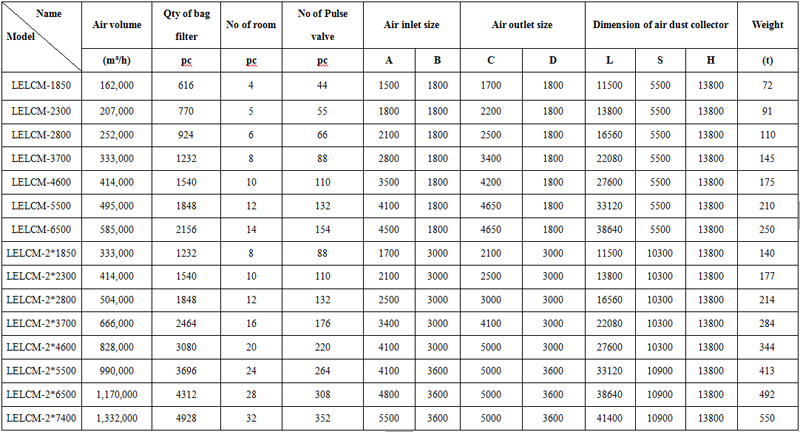

Brand Name: LEFILTER

Model Number: hc9600fkp13h

Nominal filtration rating:

Application:metallurgical industry steelmaking blast furnace, raw coal injection preparation plant, building mate

Operating pressure:

Working temperature:

Replacement or not:Replacement

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()