Nowadays, everything is evaluated by quality, and no exception for oil. Although we can get pyrolysis oil from waste tire, rubber or plastic by pyrolysis plant and the oil can be applied to generators, ships and trucks, it seems lots of people would like to pursue higher quality oil, like diesel and gasoline. Thereby, the pyrolysis oil distillation becomes a very hot and highly profitable green project, which cost low, collect raw material easily and convert pyrolysis oil to diesel or gasoline efficiently (oil recovery rate is about 90%). The machine uses the green technology to realize the distillation of the crude or waste oil and finally produces the diesel or other oil. The waste oil mainly includes the recycled engine oil from cars, trucks, etc. and the pyrolysis oil which is produced by using the pyrolysis technology to process the waste materials, such as waste plastic, waste tyre, waster rubber, oil sludge as well as biomass. Then the waste oil will be refined in the crude oil distillation machine with the high temperature into diesel. The products of crude oil distillation are mainly the diesel and gasoline.

What’s worthy of being mentioned is that the products we have researched are capable of processing both oil refined by pyrolysis equipment and variety of waste oil, such as used engine oil, slag oil, crude oil, raw oil, waste fuel oil and so on. It is also called as used engine oil recycle equipment, waste oil to fuel oil machine, etc. Here we’d like to introduce more detailed information for you, our distinguished customers.

Main features of distillation plant

1) Semi-continuous production, less artificial, the cost of production.

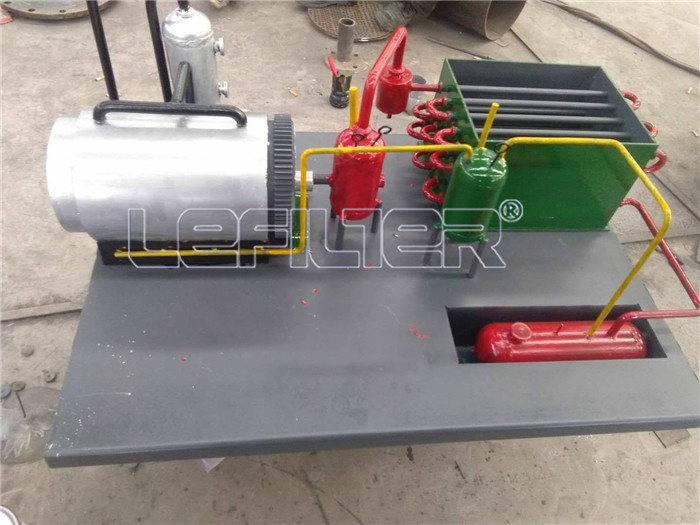

2) Unique horizontal design, the oil rate as high as 90%,100% conversion rate, high efficiency, considerable profits.

3) Good oil,good quality,can replace the use of GB diesel.

4) Safety: automatic submerged arc welding technology, ultrasonic non-destructive testing,manual and automatic installation device.

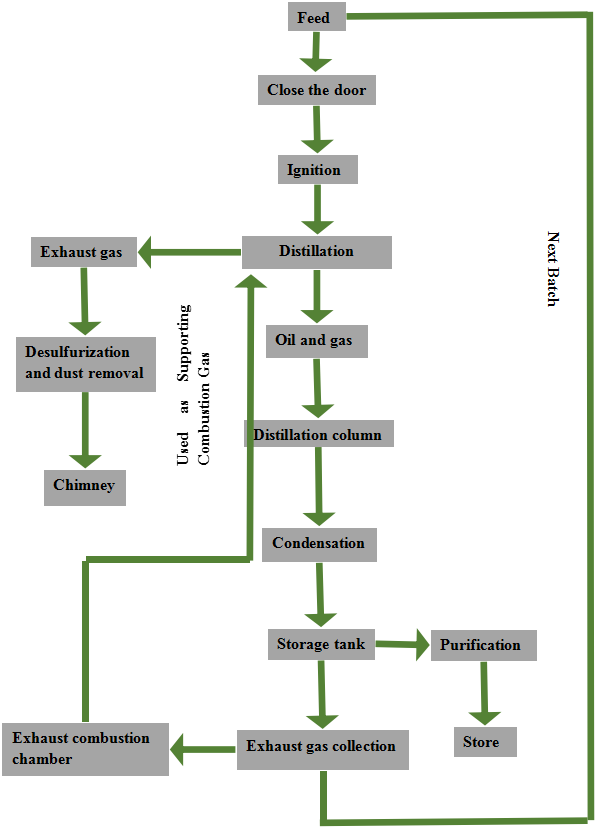

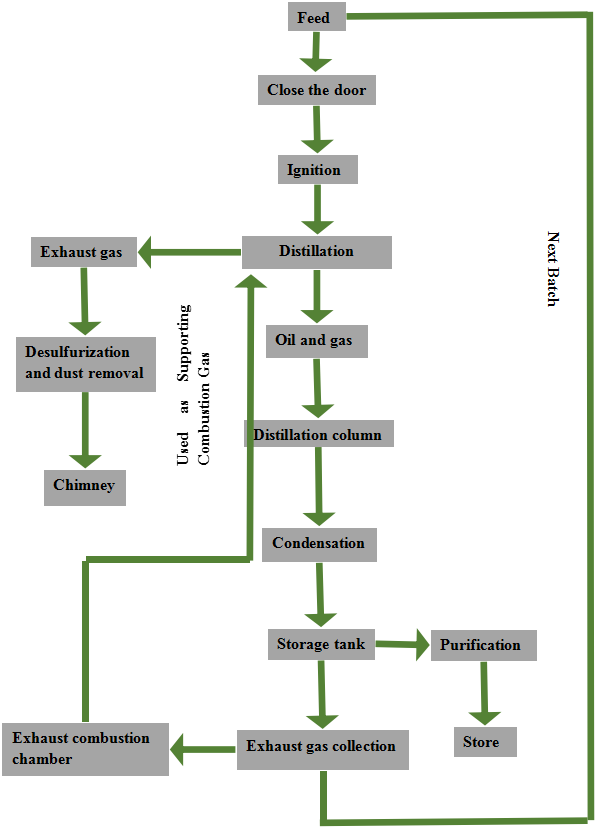

5) Exhaust gas recovery system: full combustion after recovery,save burning, prevent pollution.

6) Unique thermal insulation design: excellent thermal insulation effect, good energy-saving effect.

7) Condenser cooling completely, the high rate of oil, oil quality, long life, easy to clean.

8) Original water film desulfurization dust: can effectively remove acid gases and dust, reaching the relevant national standards.

Our services include:

1. Design the layout drawings according to the site of customers.

2. For each set of pyrolysis oil distillation plant, one engineer will be sent to complete the installation, test the machine and train the workers.

3.After-service department will give periodical call visit to make sure there is no problem of the equipment or find the problem timely and solve it immediately.

{sval:sql sql='SELECT n_parameter FROM dede_addonarticle WHERE aid = ~aid~ ' } {/sval:sql}

{sval:sql sql='SELECT n_parameter FROM dede_addonarticle WHERE aid = ~aid~ ' } {/sval:sql}