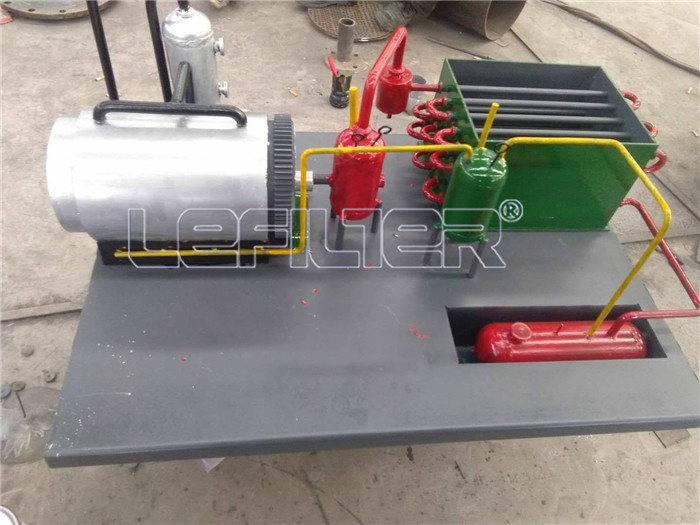

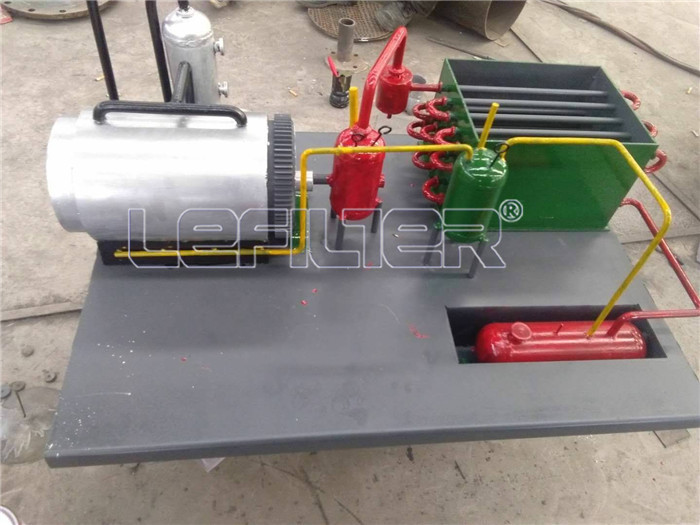

Lefilter waste tire recycling equipment uses thermal decomposition technology to decompose macromolecules into smaller molecules when high temperature.

It is 100% recycling equipment, not only a profitable business, but also helpful for improving the local environment, avoid garbage pollution.

FAQ ----

Q1: What fuel does the plant need?

A: Any types, like natural gas, diesel oil,wood,etc.

Q2: How many operators are needed during processing?

A: It depends on equipment you buy,if it’s automatic,just 1 worker,otherwises,4-6 workers.

Q3: Will it need to cut the waste tires before feeding?

A:If you don’t want to cut,it’s ok.But we advise you cutting .It’ll be easier to process with high efficiency.

Q4: Will the tire steel wire need to be removed before feeding?

A: If you don’t want to remove,it’s ok.But we advise you removing it.The steel wire can be sold at better price and benefits you.

Q5: Is the oil yield stable?What does aspect it?

A:The above oil yield is theoretical value,but many factors would affect the oil yield.

1).Raw material:different tire would have a different oil yield, bigger tires would have a higher oil yield.

2).During the tires using and storage, oxidation degree would affect the oil yield of the material.

3).Environmental temperature would influence temperature of the condensing water, which directly affect the oil yield, we can used a water condensing tower to keep the condensing water cool.

4).The pyrolysis plant operation would affect the condensing efficient, proper control of fire and heating would ensure efficient oil condensing and oil quality.

Q6: Is there bad smell during the pyrolysis processing?

A: The entire processing is in sealed, no oil or gas is outlet, so there’s no bad smell during processing. But slight smell would produced during oil transfer.

Q7: How to clean the emission to meet environmental standard?

A:After our engineers over 10 years test&improvement,now it is 0 emission.Our pyrolysis equipment is sealed,there is purification system and the gas also can be burned as fuel for the operation,it’s environmental recycling totally.

Q8: How about your after-sales service?

A: We have experienced after-sales service engineers and staff, who’s always ready to install and guide to operate it.

Q9: Can I mix tire, plastic or other together to operate?

A: Generally, we don’t recommend you to mix them. Tire and plastic need different temperature and time to be processed. If you put them together, much fuel will be wasted. Besides, the quality and rate of final oil will also change.

{sval:sql sql='SELECT n_parameter FROM dede_addonarticle WHERE aid = ~aid~ ' } {/sval:sql}

{sval:sql sql='SELECT n_parameter FROM dede_addonarticle WHERE aid = ~aid~ ' } {/sval:sql}